Ultrasonic puncture instrument capable of rotatably sampling

An instrument and ultrasonic technology, applied in the directions of puncture needles, puncture needles, suction instruments, etc., can solve the problems of danger, inability to obtain enough biopsy tissue, and large damage to skin and tissue, and achieve the effect of reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

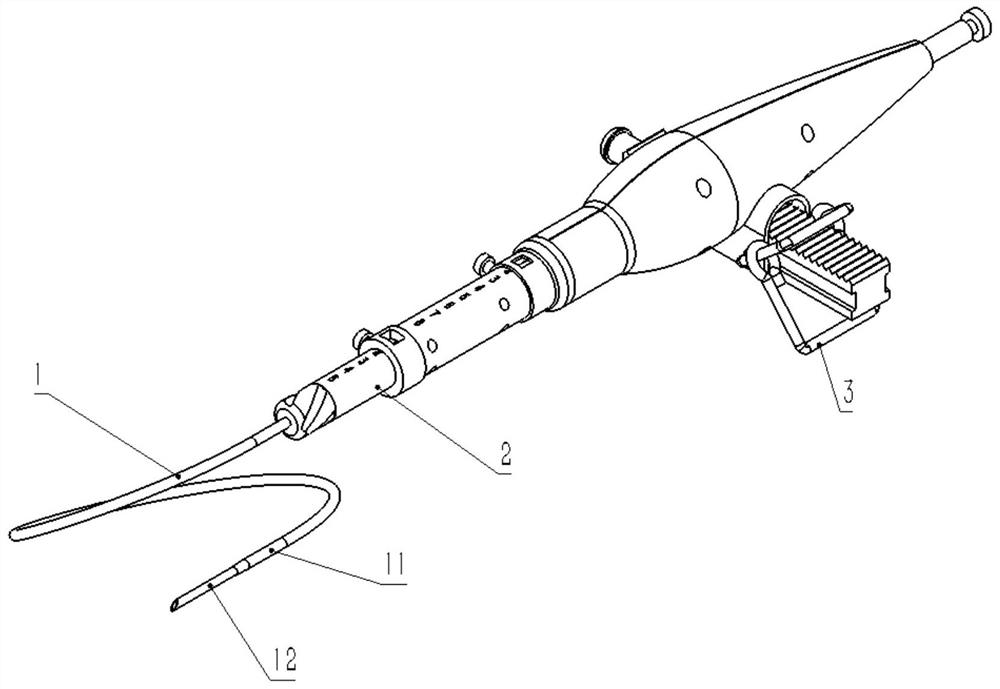

[0062] Such as figure 1 As shown, it is a rotatable sampling ultrasonic puncture instrument of this embodiment, which includes a needle tube assembly 1 and an adjustment assembly 2 for adjusting the position of the needle tube; the needle tube assembly 1 includes an outer sheath tube 11 and an inner rotating needle 12; The needle 12 is arranged inside the outer sheath tube 11; the adjustment assembly 2 includes a position adjustment structure and a power assembly for driving the needle tube assembly 1 to rotate; the power assembly is arranged inside the position adjustment structure and is connected with the position adjustment structure; the inner rotating needle 12 It is connected with the power structure; the positioning structure includes the front end adjustment tube 22 and the middle adjustment tube 23; the outer sheath tube 11 is connected with the front end adjustment tube 22; the inner rotating needle 12 is connected with the middle adjustment tube 23.

[0063] The po...

Embodiment 2

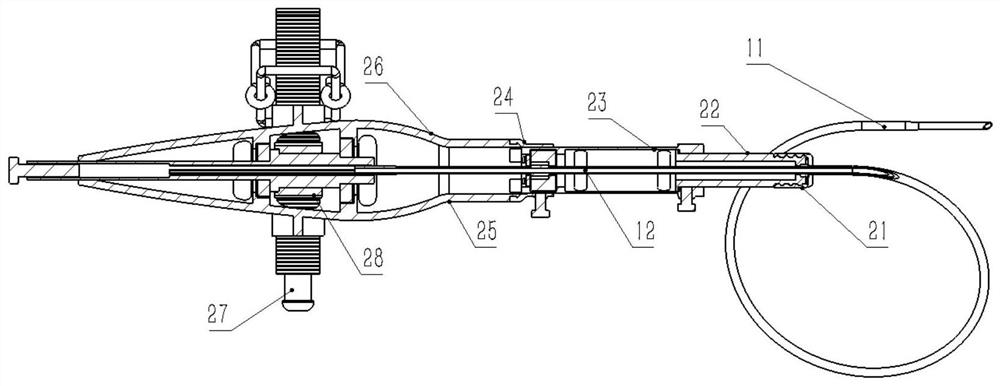

[0068] Such as Figure 2-4 As shown, the following technical features are specifically set on the basis of Embodiment 1 for this embodiment:

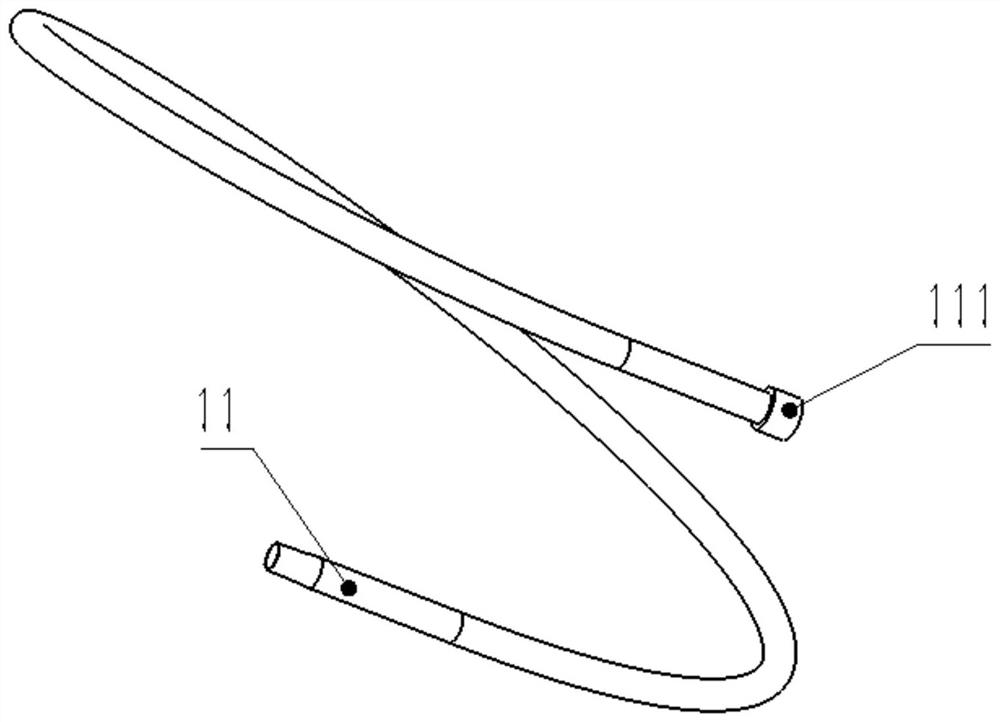

[0069] The inner rotating needle 12 is arranged inside the outer sheath tube 11; the bottom of the outer sheath tube 11 is provided with the outer sheath tube fixing seat 111, and the outer sheath tube 11 is integrally connected with the outer sheath tube fixing seat 111; the outer sheath tube fixing seat 111 It is plugged with the front end adjustment tube 22; the middle part of the inner rotation needle 12 is provided with an inner rotation needle fixing seat 121 for plugging with the middle adjustment tube 23; the bottom of the inner rotation needle 12 is plugged with the connection seat 122; one end of the connection seat 122 is connected to the The inner rotating needle 12 is plugged in, and the other end is plugged in with the tube plug 123; when the tube plug 123 is opened, the inner rotating needle 12 and the connecting seat 122...

Embodiment 3

[0072] Such as Figure 5-12 As shown, the following technical features are specifically set on the basis of Embodiment 2 for this embodiment:

[0073] One end of the front end adjustment tube 22 is threadedly connected with the end cover 21, and the other end is plugged with the middle adjustment tube 23; one end of the middle adjustment tube 23 is plugged with the front end adjustment tube 22, and the other end is plugged with the fixed ring 24; the inside of the fixed ring 24 is connected to the middle The regulating pipe 23 is plugged in, and one end is detachably connected with the outer casing.

[0074] The end cap 21 is a circular cylindrical structure, and an internal thread for threaded connection with the front end adjustment pipe 22 is provided inside.

[0075] The front end locking structure 2213 at one end of the marking rod one 222 is fixedly connected, and the other end is fixedly connected with the slider 223;

[0076] The front-end locking structure 2213 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com