Hydroxypropyl methylcellulose hollow capsule and preparation process thereof

A technology of hypromellose and hydroxypropyl methylcellulose, which is applied in the field of hypromellose hollow capsules and their preparation, can solve the problems of incomplete dissolution of hypromellose and low energy consumption, and achieves No food safety risk, ingredient safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

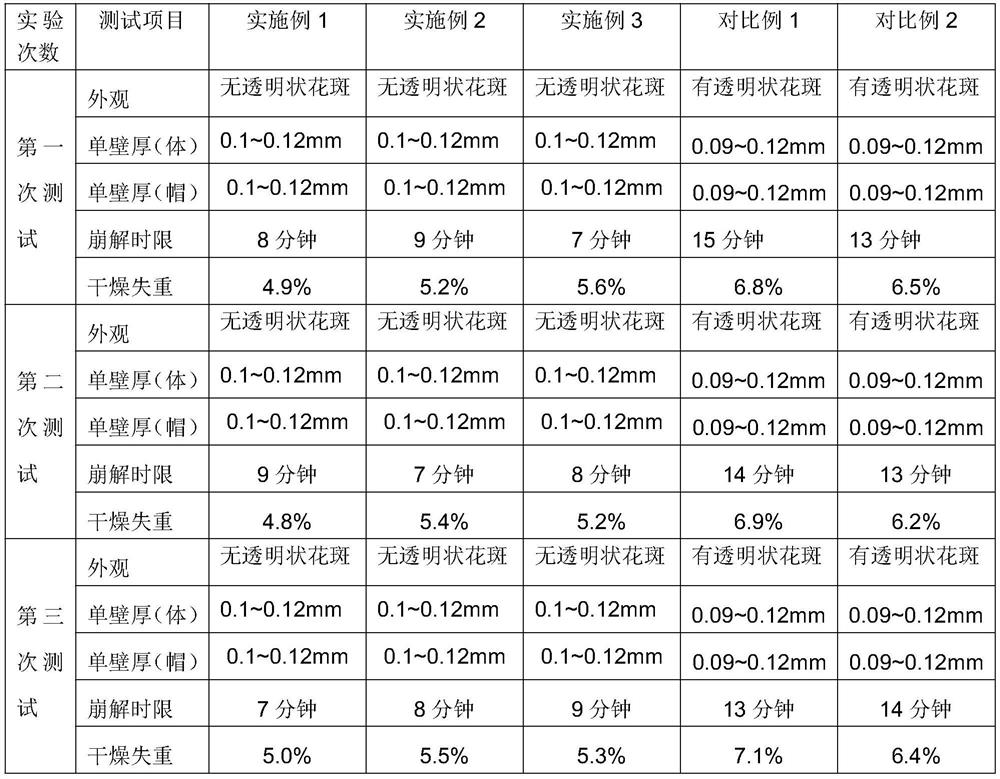

Examples

Embodiment 1

[0022] Low-temperature hypromellose hollow capsule production process, weighing the following components: hydroxypropyl methylcellulose 10kg, carrageenan (BL9002) 140g, carrageenan (BLI 1120) 30g, potassium chloride 35g, sodium acetate 35g , polyethylene glycol 6008g, 15°C purified water 45kg.

[0023] The above-mentioned low-temperature hypromellose hollow capsule production process comprises the following steps:

[0024] Step 1, weigh the following components in parts by weight: hydroxypropyl methylcellulose 10kg, carrageenan (BL9002) 140g, carrageenan (BLI 1120) 30g, potassium chloride 35g, sodium acetate 35g, polyethylene glycol Alcohol 6008g, 15°C purified water 45kg.

[0025] Step 2, weigh 35kg of purified water at 15°C, add the full amount of hydroxypropyl methylcellulose and polyethylene glycol 600, and stir continuously at 15°C for 2 hours until it dissolves into a transparent glue ①;

[0026] Step 3, weigh 8kg of purified water, add the full amount of carrageenan (...

Embodiment 2

[0030] Low-temperature hypromellose hollow capsule production process, weighing the following components: hydroxypropyl methylcellulose 10kg, carrageenan (BL9002) 170g, carrageenan (BLI 1120) 20g, potassium chloride 44g, sodium acetate 44g , polyethylene glycol 6008g, 25°C purified water 45kg.

[0031] The above-mentioned low-temperature hypromellose hollow capsule production process comprises the following steps:

[0032] Step 1, weigh the following components in parts by weight: hydroxypropyl methylcellulose 10kg, carrageenan (BL9002) 170g, carrageenan (BLI 1120) 30g, potassium chloride 44g, sodium acetate 44g, polyethylene glycol Alcohol 6008g, 25°C purified water 45kg.

[0033] Step 2, weigh 35kg of purified water at 25°C, add the full amount of hydroxypropyl methylcellulose and polyethylene glycol 600, and stir continuously at 25°C for 2 hours until it dissolves into a transparent glue ①;

[0034] Step 3, weigh 8kg of purified water, add the full amount of carrageenan (...

Embodiment 3

[0038] Low-temperature hypromellose hollow capsule production process, weighing the following components: hydroxypropyl methylcellulose 10kg, carrageenan (BL9002) 180g, carrageenan (BLI 1120) 40g, potassium chloride 40g, sodium acetate 40g , polyethylene glycol 6008g, 30°C purified water 45kg.

[0039] The above-mentioned low-temperature hypromellose hollow capsule production process comprises the following steps:

[0040] Step 1, weigh the following components in parts by weight: hydroxypropyl methylcellulose 10kg, carrageenan (BL9002) 180g, carrageenan (BLI 1120) 40g, potassium chloride 40g, sodium acetate 40g, polyethylene glycol Alcohol 6008g, 30°C purified water 45kg.

[0041] Step 2, weigh 35kg of purified water at 30°C, add the full amount of hydroxypropyl methylcellulose and polyethylene glycol 600, and stir continuously at 35°C for 2 hours until it dissolves into a transparent glue ①;

[0042] Step 3, weigh 8kg of purified water, add the full amount of carrageenan (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com