Metal powder and preparation method thereof, and metal alloy and preparation method thereof

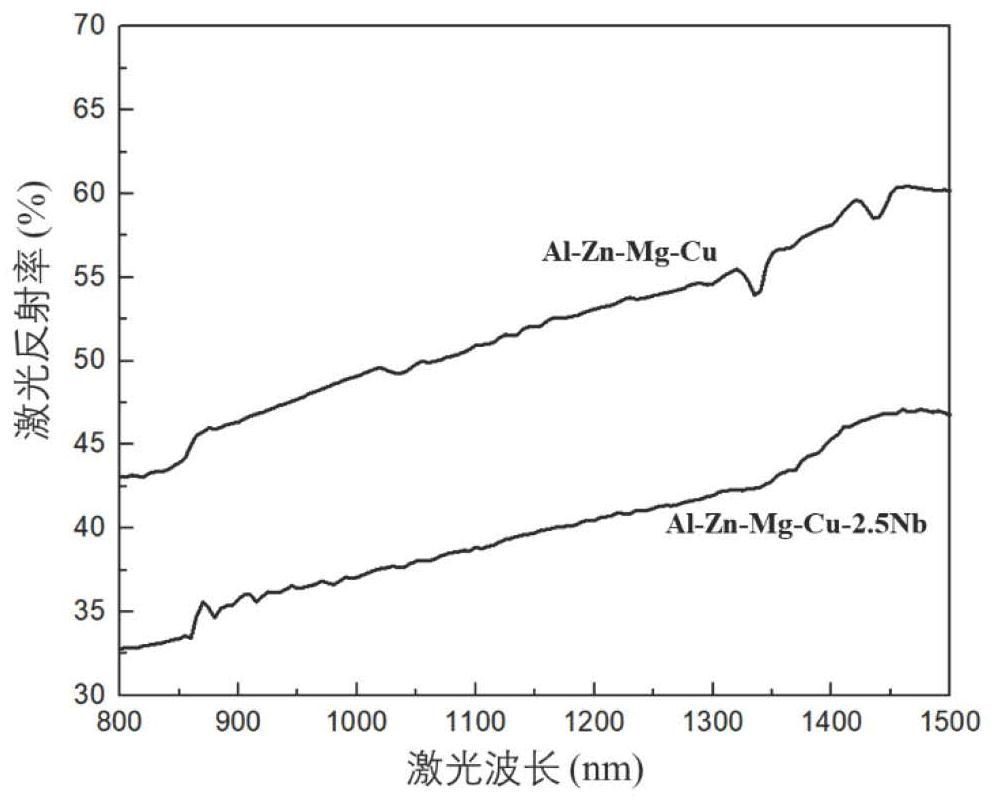

A metal powder and metal alloy technology, applied in the field of alloys, can solve the problems of high thermal cracking sensitivity of aluminum alloys, failure to meet the needs of use, and easy cracks, etc., to improve the laser absorption rate, promote the transformation to fine equiaxed crystals, The effect of reducing the probability of crack generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In a second aspect, the embodiment of the present application provides a method for preparing the metal powder according to the embodiment of the first aspect, comprising: mixing aluminum alloy powder and niobium to obtain metal powder.

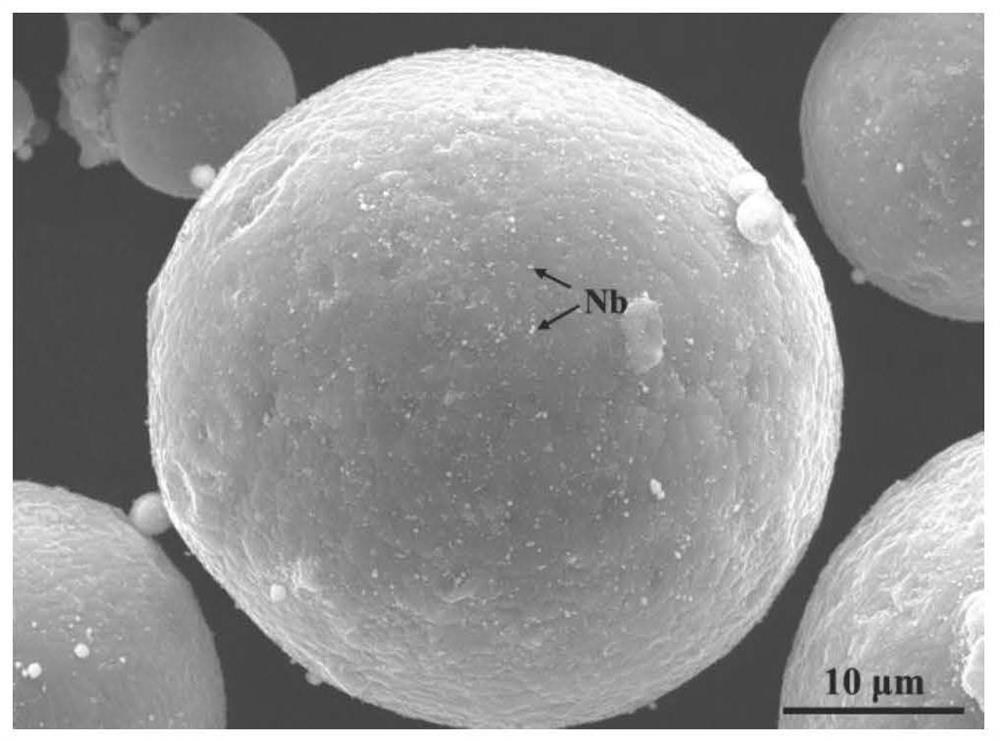

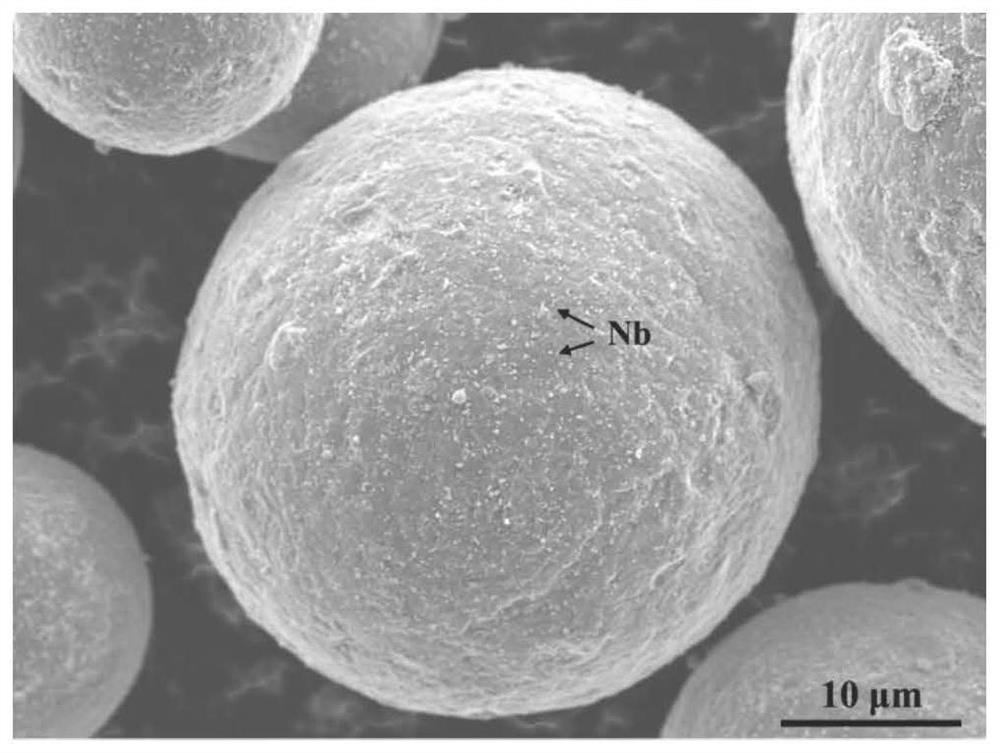

[0043] The particle size of niobium is ≤200nm. Nano-shaped niobium has a small size effect. In the process of mixing with aluminum alloy powder, the characteristics of large specific surface area and insufficient coordination of surface atoms make it under the action of van der Waals force. Spontaneously attaching to the surface of the aluminum alloy powder forms the metal powder of the embodiment of the present application.

[0044] In addition to aluminum, the aluminum alloy powder also contains other metal elements. The inventors of the present application have found that if aluminum micropowder, other metal element micropowders and Nb nanopowder are directly mixed and then melted, the composition of the metal alloy will easily be fo...

Embodiment 1

[0065] This embodiment provides a metal powder, which includes aluminum alloy powder and niobium on the surface of the aluminum alloy powder, the particle size of the aluminum alloy powder is 10-60 μm, the particle size of niobium is 20-200 nm, and the mass of niobium is 100 μm of the metal powder. 1.5% of mass. Among them, the aluminum alloy powder includes by weight percentage: Zn: 4.8wt%, Mg: 2.3wt%, Cu: 1.8wt%, Cr: 0.18wt%, impurity elements <0.15wt%, O≤0.05wt%, N≤ 0.05wt% and the rest of Al, impurity elements include Fe, Si, Mn and Ti.

[0066] This embodiment provides a method for preparing the above-mentioned metal powder, the preparation steps of which include:

[0067] (1) Melt Al, Zn, Mg and Cu metal blocks at 700°C, hold for 10 minutes, and cast them into 7-series Al-Zn-Mg-Cu alloy ingots, and control the content of Fe, Si, Mn and Ti to less than 0.15wt %, control the content of O and N to be lower than 0.03wt%.

[0068] (2) Melting the alloy ingot prepared in st...

Embodiment 2

[0075] This embodiment provides a metal powder, which includes aluminum alloy powder and niobium on the surface of the aluminum alloy powder. 2% of mass. Among them, the aluminum alloy powder includes by weight percentage: Zn: 5.1wt%, Mg: 2.1wt%, Cu: 1.9wt%, Cr: 0.18wt%, impurity elements <0.15wt%, O≤0.05wt%, N≤ 0.05wt% and the rest of Al, impurity elements include Fe, Si, Mn and Ti.

[0076] This embodiment provides a method for preparing the above-mentioned metal powder, the preparation steps of which include:

[0077] (1) Melt Al, Zn, Mg and Cu metal blocks at 700°C, hold for 10 minutes, and cast them into 7-series Al-Zn-Mg-Cu alloy ingots, and control the content of Fe, Si, Mn and Ti to less than 0.15wt %, control the content of O and N to be lower than 0.03wt%.

[0078] (2) Melting the alloy ingot prepared in step (1) to obtain alloy powder by gas atomization, and drying the alloy powder by using vacuum pneumatic sieve to obtain aluminum alloy powder with a particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com