Magnetic fixing device for prefabricated part mold

A technology of prefabricated components and fixtures, applied in the direction of mold fixtures, manufacturing tools, mold auxiliary parts, etc., can solve the problems of weak structural reliability, affecting the service life of steel rings, reducing bonding force, etc., and achieving the utilization rate of magnets Effective, guaranteeing performance durability, reducing the effect of tolerance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

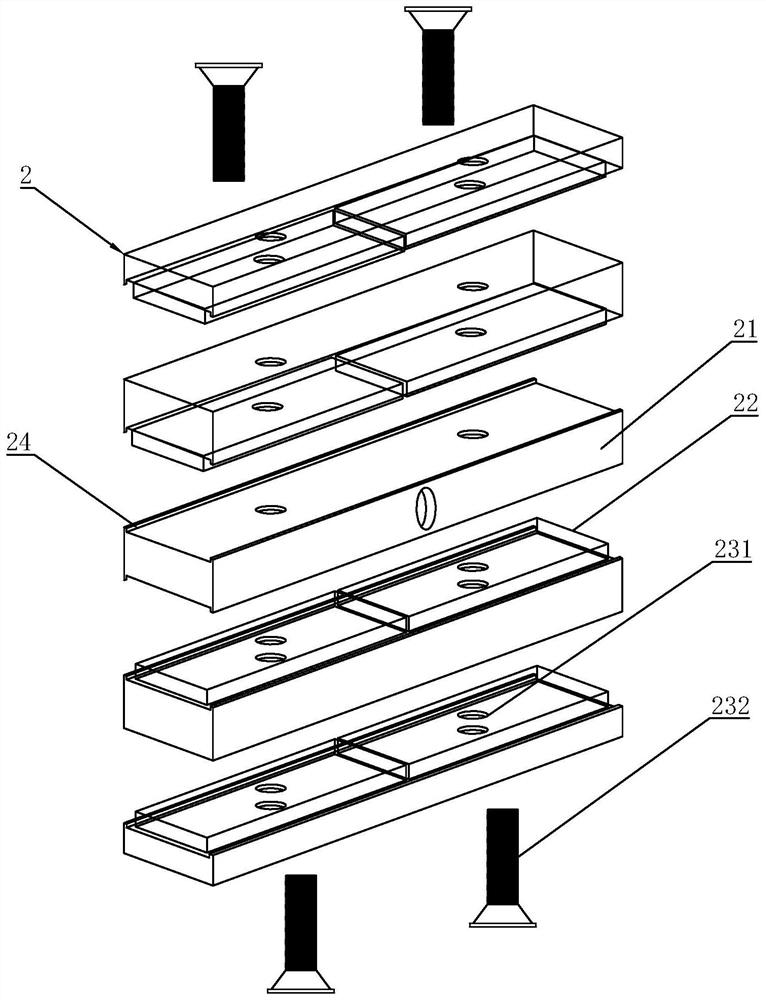

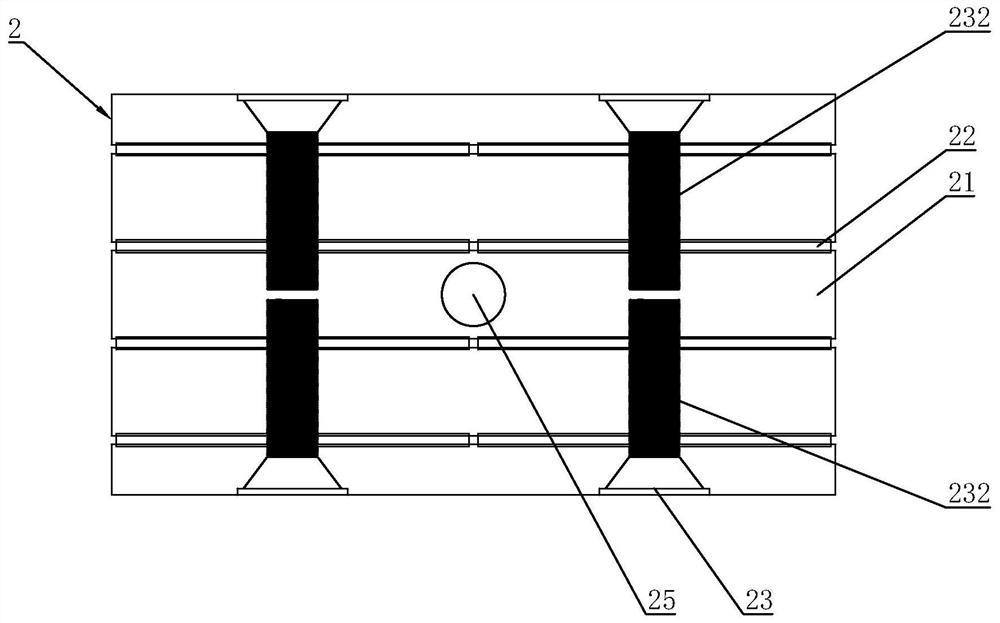

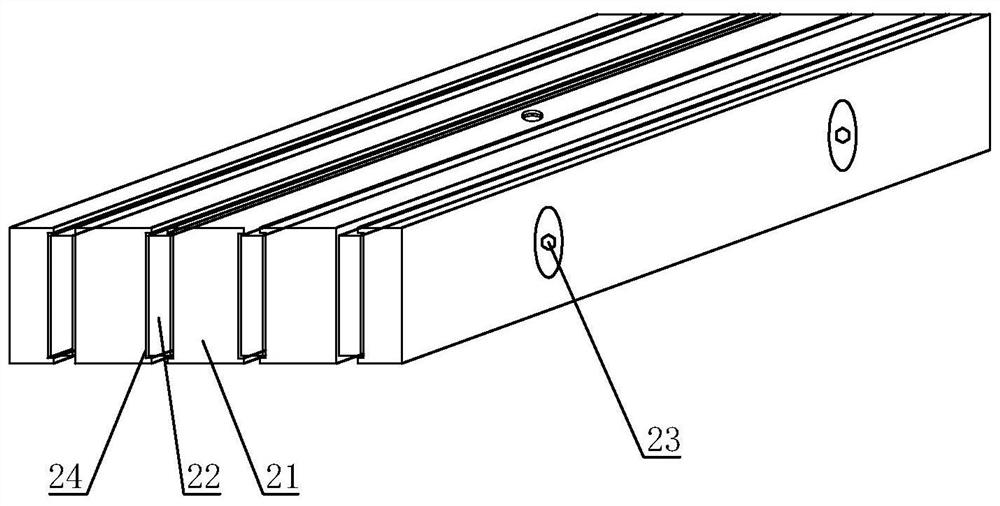

[0025]As shown in the figure, a magnetic fixing device for a prefabricated component mold includes an outer casing 1, an installation cavity 11 is opened at the bottom of the outer casing 1, and a magnetic seat assembly 2 is movable up and down in the installation cavity 11, and the top of the outer casing 1 A magnetic control mechanism 3 that is connected to the magnetic base assembly 2 and can control the up and down movement of the magnetic base assembly 2 is provided. The outer shell 1 is also provided with a mold fixing mechanism 4 for fixing the mold of the prefabricated component. The magnetic base assembly 2 includes at least three guides. Magnetic fixed block 21, the permanent magnet 22 that is arranged between adjacent magnetically permeable fixed blocks 21 and the fastening mechanism 23 that all magnetically permeable fixed blocks 21 and permanent magnets 22 are connected as a whole, on the magnetically permeable fixed block 21 and permanent magnet 22 is provided wit...

Embodiment 2

[0028] This embodiment proposes a magnetic fixing device for a prefabricated component mould. On the basis of the first embodiment, the specific structure of the groove is supplemented. In this embodiment, the groove depth of the groove 24 is 0.5mm. In other embodiments, the groove depth can also be 0.3, 0.8, 1.0mm, etc., and the surface gap between adjacent magnetically permeable fixing blocks 21 is 1.5mm. In other embodiments The surface gap can also be 1.0, 1.2, 1.8, 2.0, 2.5 mm, etc.

Embodiment 3

[0030] This embodiment proposes a magnetic fixing device for a prefabricated component mould, which provides a supplementary description of the specific structure of the fastening mechanism on the basis of Embodiment 1 or 2. In this embodiment, the fastening mechanism 23 is composed of a threaded hole 231 vertically penetrating through the magnetically permeable fixed block 21 and the permanent magnet 22 and a pair of fastening bolts 232 symmetrically arranged in the threaded hole 231. The threaded holes 231 cooperate to connect all the magnetically permeable fixing blocks 21 and the permanent magnets 22 as a whole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com