Compression molding system and method for automotive upholstery

A technology for automotive interior parts and press molding, which is applied in the field of auto parts production, can solve the problems of carpet wrinkles, improper demoulding, carpet demoulding burrs, etc., and achieve the effects of strong anti-wrinkle ability, improved pressing effect, and stable demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

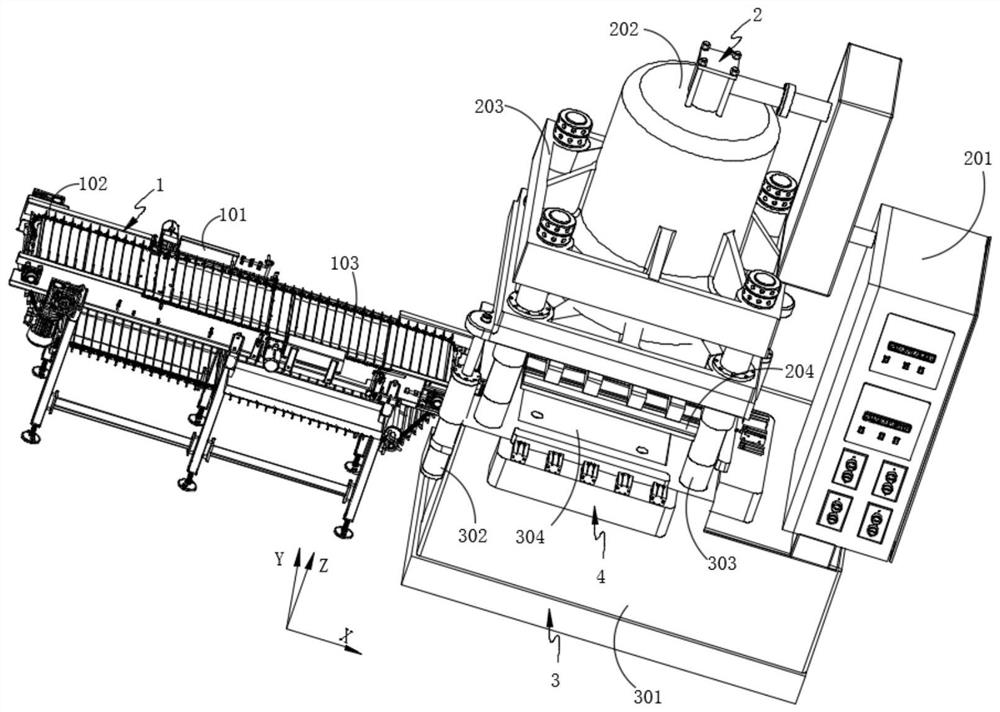

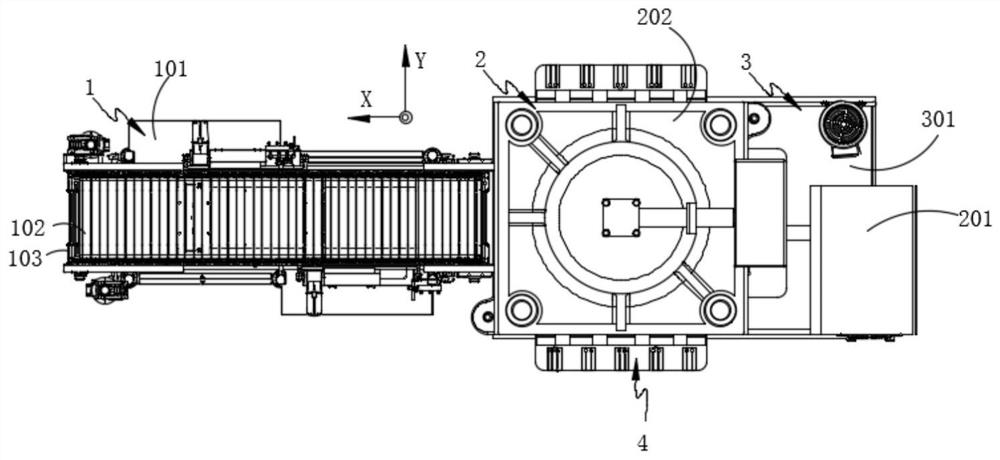

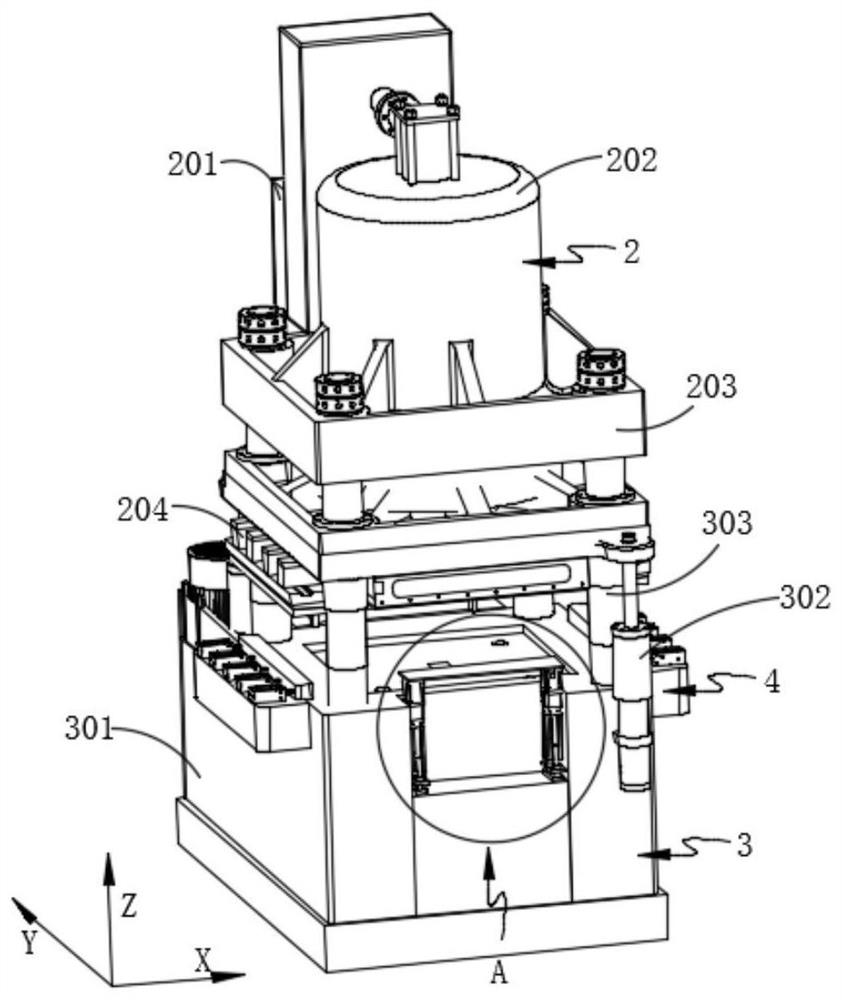

[0046] Such as Figure 1-8 As shown, a press molding system for automotive interior parts, including:

[0047] A transmission mechanism 1, the transmission mechanism 1 comprising a support frame 101;

[0048] Also includes:

[0049] A pressurizing mechanism 2, the pressurizing mechanism 2 is installed on one side of the transmission mechanism 1;

[0050] A pressing mechanism 3, the pressing mechanism 3 is arranged at the bottom of the pressing mechanism 2;

[0051] A pushing mechanism 4, the pushing mechanism 4 is connected to the outside of the pressing mechanism 3;

[0052] A demoulding unit 5, the demoulding unit 5 is arranged inside the pressing mechanism 3;

[0053] The pushing mechanism 4 pushes the composite material to the central position of the pressing mechanism 3, so that the pressing mechanism 2 and the pressing mechanism 3 can press and shape the composite material.

[0054]Further, such as figure 1 As shown, the surface of the support frame 101 is provided...

Embodiment 2

[0068] A method for press-molding an automotive interior trim using a press-molding system for an automotive interior trim described in the first technical solution of the above-mentioned embodiment comprises the following steps:

[0069] Step 1: transporting materials; placing the softened composite material on the surface of the transmission mechanism 1, so that the transmission mechanism 1 transports the composite material to the interior of the pressing mechanism 3;

[0070] Step 2: pushing and positioning; through the movement of the pushing mechanism 4, the pushing mechanism 4 on the outside of the pressing mechanism 3 is converged to the inside, so that the composite material is moved to the center of the top surface of the pressing mechanism 3, and the pushing mechanism 4 Reset after moving to the specified position;

[0071] Step 3: pressing, through the closing of the pressing mechanism 3 and the pressing mechanism 2, the pressing mechanism 2 performs shaping and pre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap