Modified asphalt mixture and preparation method thereof

A modified asphalt and mixture technology, which is applied in the field of modified asphalt mixture and its preparation, can solve problems such as resource scarcity and ecological damage, and achieve the effects of reducing early damage, prolonging service life, and enhancing the performance of asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of modified asphalt mixture comprises the following steps:

[0041] Step 1, adding 88 parts of aggregate and 10 parts of filler into the stirring device for dry mixing;

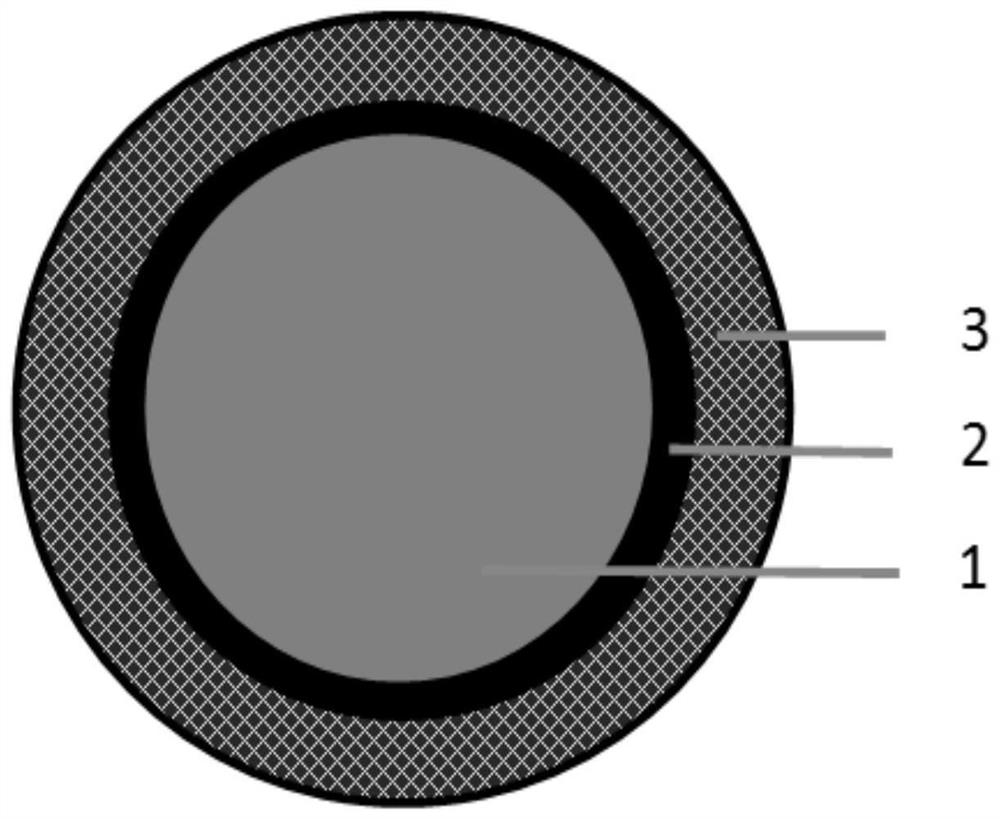

[0042] Step 2: Transport 2 parts of epoxy-modified asphalt (a kind of thermosetting resin-modified asphalt) from the asphalt insulation tank 1 to the mixing device, and fully mix it so that the surface of the aggregate and filler forms a first layer of heat-fixing modification Asphalt film to obtain a thermosetting modified asphalt premix;

[0043] Step 3: Transport 4 parts of SBS modified asphalt (one of the SBS polymers) from the asphalt insulation tank 2 to the mixing device for full mixing, so that a second layer of thermoplastic modified asphalt film is formed on the surface of the aggregate and filler.

Embodiment 2

[0045] Step 1. Add 94 parts of aggregate and 5 parts of filler into the stirring device for dry mixing;

[0046] Step 2: Transport 1 part of epoxy-modified asphalt from the asphalt insulation tank 1 to the mixing device, and fully mix it so that the first layer of thermally fixed modified asphalt film is formed on the surface of the aggregate and filler to obtain a thermosetting modified asphalt premix ;

[0047] Step 3: Transport 8 parts of SBS modified asphalt from the asphalt insulation tank 2 to the mixing device for full mixing, so that a second layer of thermoplastic modified asphalt film is formed on the surface of the aggregate and filler.

Embodiment 3

[0049] Step 1. Add 98.5 parts of aggregate and 1 part of filler into the mixing device for dry mixing;

[0050] Step 2: Transport 0.5 parts of epoxy-modified asphalt from the asphalt insulation tank 1 to the mixing device, and fully mix it so that the first layer of thermally fixed modified asphalt film is formed on the surface of the aggregate and filler to obtain a thermosetting modified asphalt premix ;

[0051] Step 3: Transport 10 parts of SBS modified asphalt from the asphalt insulation tank 2 to the mixing device for full mixing, so that a second layer of thermoplastic modified asphalt film is formed on the surface of the aggregate and filler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com