CuS@Ni(OH)2 double-layer structure composite cube

A double-layer structure and cube technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor conductivity utilization, etc., and achieve the effect of short reaction cycle, stable structure and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

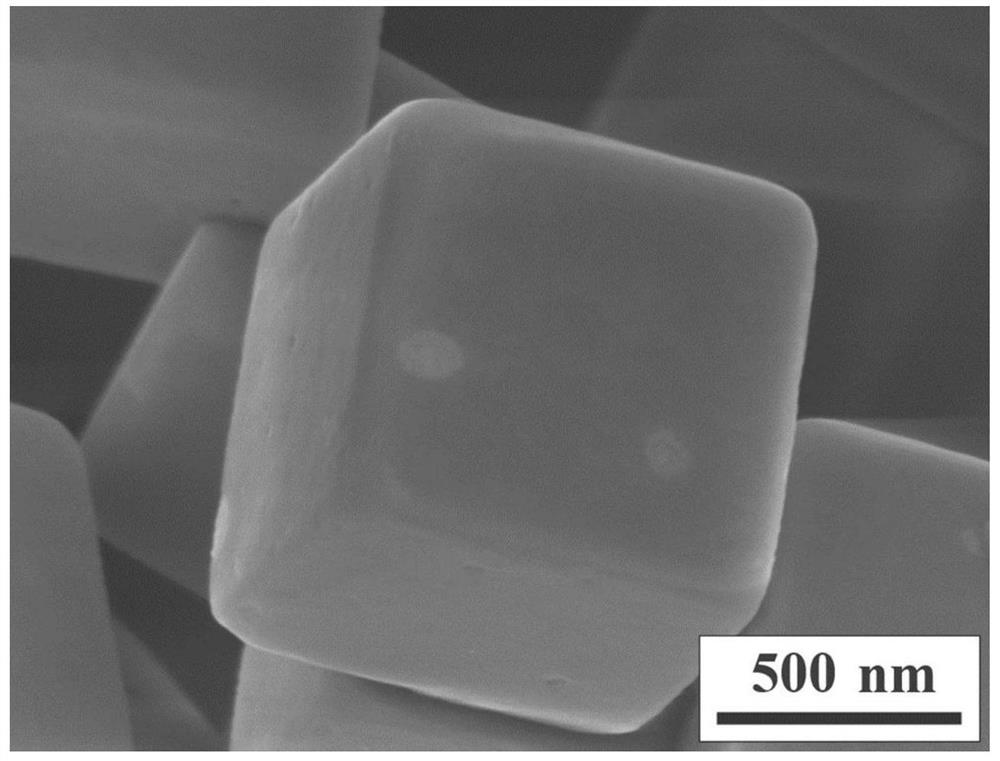

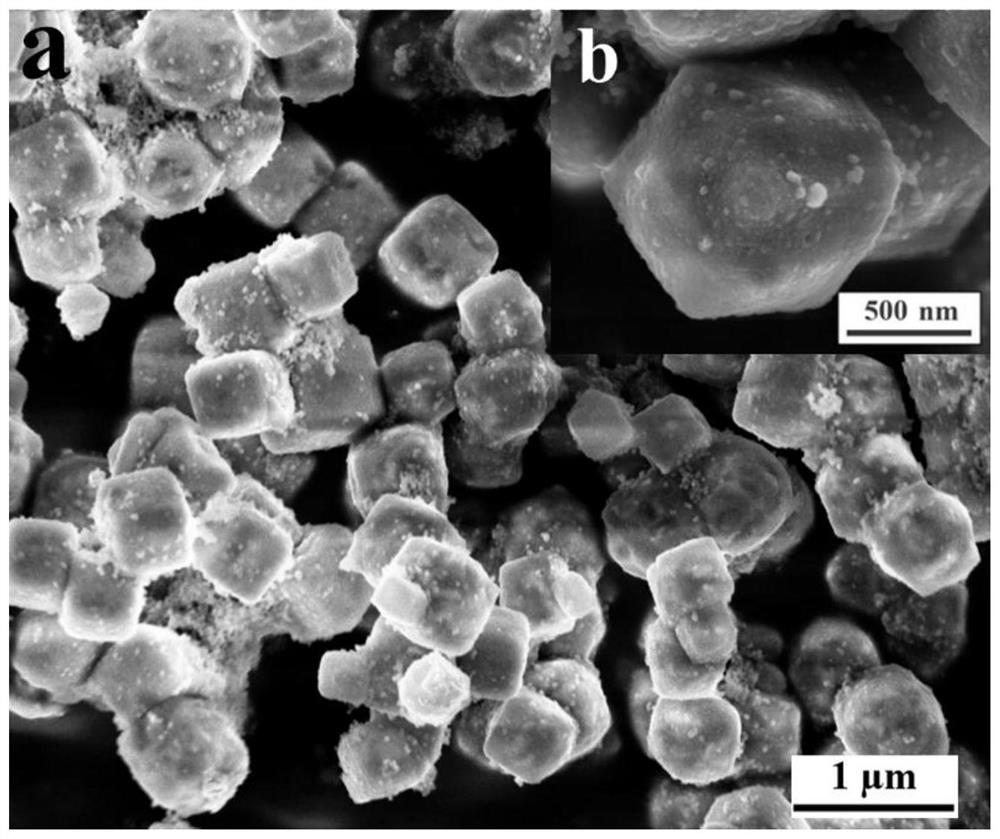

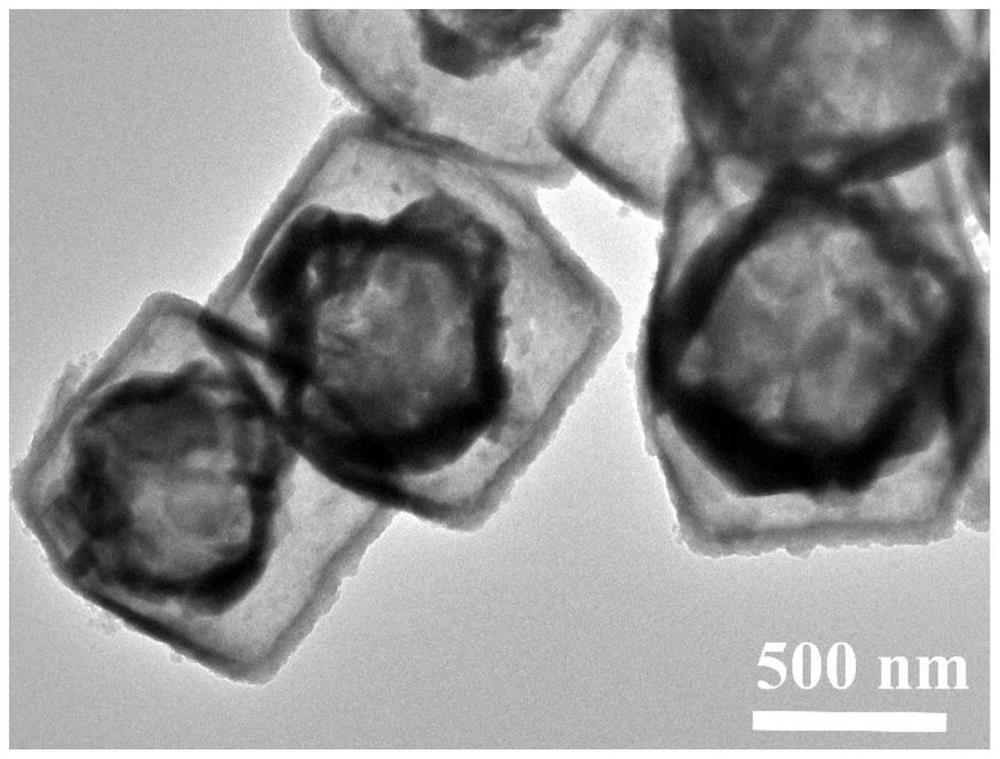

Embodiment 1

[0022] Weigh 100mg Cu 2 O cubic template and 35mg nickel chloride hexahydrate were dispersed in 100mL ethanol / deionized water mixed solution (volume ratio 1:1), ultrasonicated for 8 minutes; 3.3g polyvinylpyrrolidone (Mw=40,000) was added to the above solution, and magnetically stirred 30 minutes; 40mL sodium thiosulfate pentahydrate solution (1M) was added dropwise to the above solution, centrifuged after 2 minutes of reaction to obtain Cu 2 O@Ni(OH) 2 Composite structure; the collected precipitate was dispersed in a mixed solution of ethanol / deionized water, then 20 mL of sodium sulfide solution (0.086M) was added dropwise, and centrifuged after 10 minutes to obtain Cu 2 O@CuS@Ni(OH) 2 The composite structure was then dispersed in ethanol / deionized water mixture; finally, the remaining Cu 2 The O template was removed, and the precipitate was centrifuged, washed 5 times with water, ethanol / deionized water mixture and ethanol, and dried in an oven to obtain CuS@Ni(OH) 2 Do...

Embodiment 2

[0028] Weigh 100mg Cu 2 O cubic template and 35mg nickel chloride hexahydrate were dispersed in 100mL ethanol / deionized water mixed solution (volume ratio 1:1), ultrasonicated for 8 minutes; 3.3g polyvinylpyrrolidone (Mw=40,000) was added to the above solution, and magnetically stirred 30 minutes; 40mL sodium thiosulfate pentahydrate solution (0.6M) was added dropwise to the above solution, centrifuged after 2 minutes of reaction to obtain Cu 2 O@Ni(OH) 2 Composite structure; the collected precipitate was dispersed in a mixed solution of ethanol / deionized water, then 20 mL of sodium sulfide solution (0.086M) was added dropwise, and centrifuged after 5 minutes to obtain Cu 2 O@CuS@Ni(OH) 2 The composite structure was then dispersed in ethanol / deionized water mixture; finally, the remaining Cu 2 The O template was removed, and the precipitate was centrifuged, washed with water, ethanol / deionized water mixture and ethanol 5 times each, and dried in an oven to obtain CuS@Ni(OH)...

Embodiment 3

[0030] Weigh 100mg Cu 2 O cubic template and 35 mg of nickel chloride hexahydrate were dispersed in 100 mL of ethanol / deionized water mixed solution (volume ratio 2:1), ultrasonicated for 10 minutes; 3.3 g of polyvinylpyrrolidone (Mw=58,000) was added to the above solution, and magnetically stirred 30 minutes; 40mL sodium thiosulfate pentahydrate solution (0.6M) was added dropwise to the above solution, centrifuged after 5 minutes of reaction to obtain Cu 2 O@Ni(OH) 2 Composite structure; the collected precipitate was dispersed in a mixed solution of ethanol / deionized water, then 20 mL of sodium sulfide solution (0.086M) was added dropwise, and centrifuged after 10 minutes to obtain Cu 2 O@CuS@Ni(OH) 2 The composite structure was then dispersed in ethanol / deionized water mixture; finally, the remaining Cu 2 The O template was removed, and the precipitate was centrifuged, washed with water, ethanol / deionized water mixture and ethanol 5 times each, and dried in an oven to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com