Base supporting frame, device and method for epitaxial growth of silicon wafer

A technology of epitaxial growth and support frame, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc. It can solve the problems of uneven thickness of epitaxial layer and poor flatness of epitaxial silicon wafer, etc., and achieve good flatness and uniform thickness , the effect of balanced growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

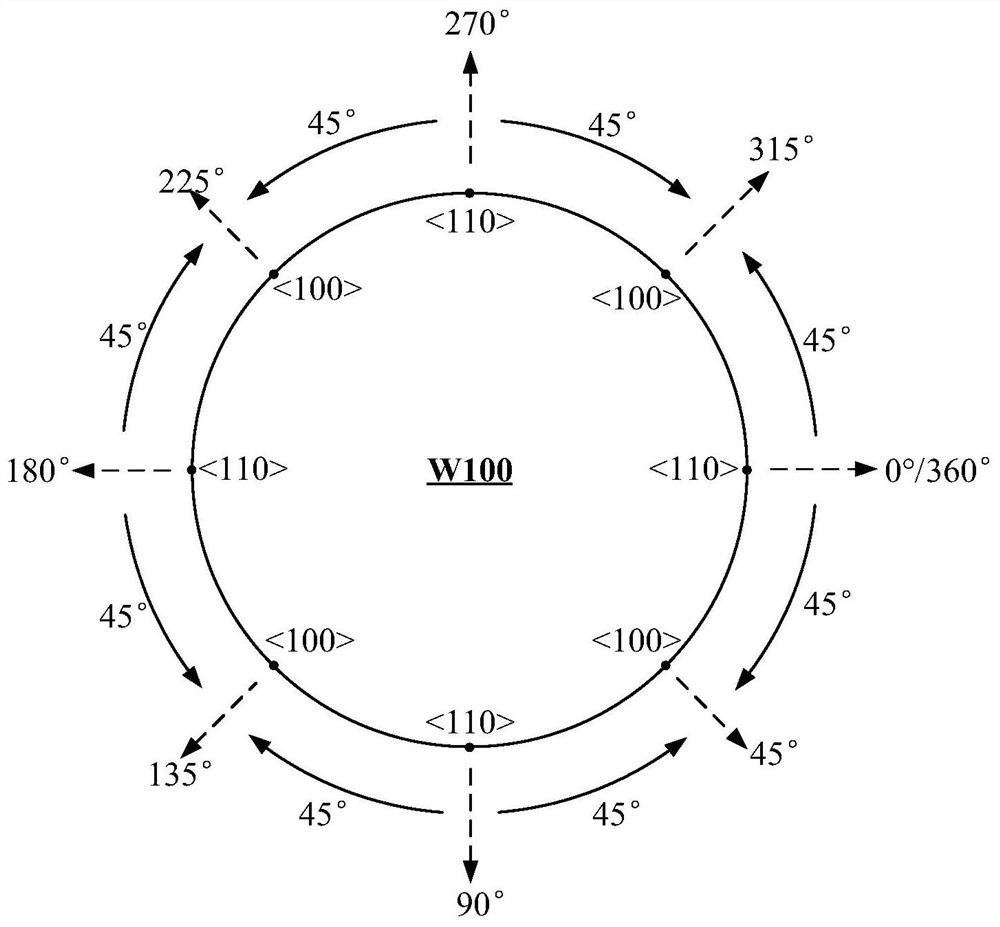

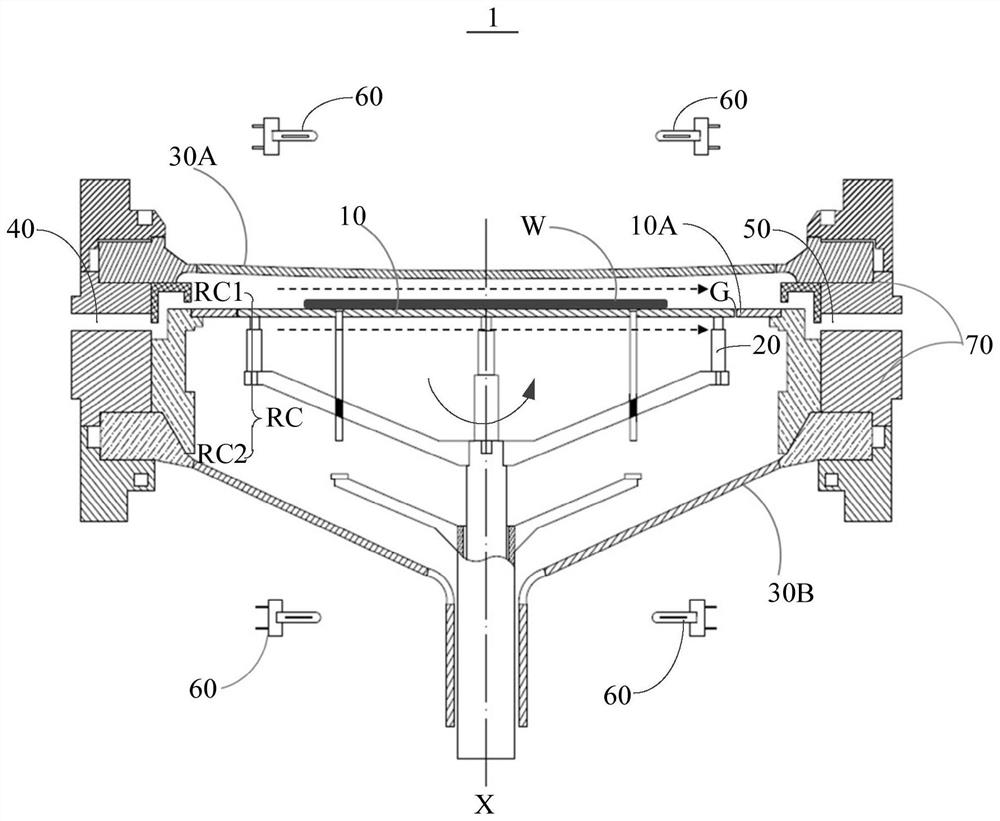

[0038] see image 3 , which shows a schematic diagram of an existing device 1 for epitaxial growth of a silicon wafer W. Such as image 3 As shown, the device 1 may include: a base 10, which is used to carry a silicon wafer W; a base support frame 20, which is used to support the base 10 and drive the base during epitaxial growth. 10 rotates around the central axis X at a certain speed, wherein during the rotation of the base 10, the silicon wafer W rotates around the central axis X together with the base 10, that is to say, the silicon wafer W remains stationary relative to the base 10, Thus, a small gap G is required between the radial edge of the susceptor 10 and the adjacent part 10A (typically the preheating ring); the upper quartz bell 30A and the lower quartz bell 30B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com