Drying device for 2,5-di-anilino-terephthalic acid production

A technology of terephthalic acid and drying device, which is applied in the directions of drying gas arrangement, drying solid materials, drying goods processing, etc., can solve the problems such as the specific structure of the undisclosed dryer, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

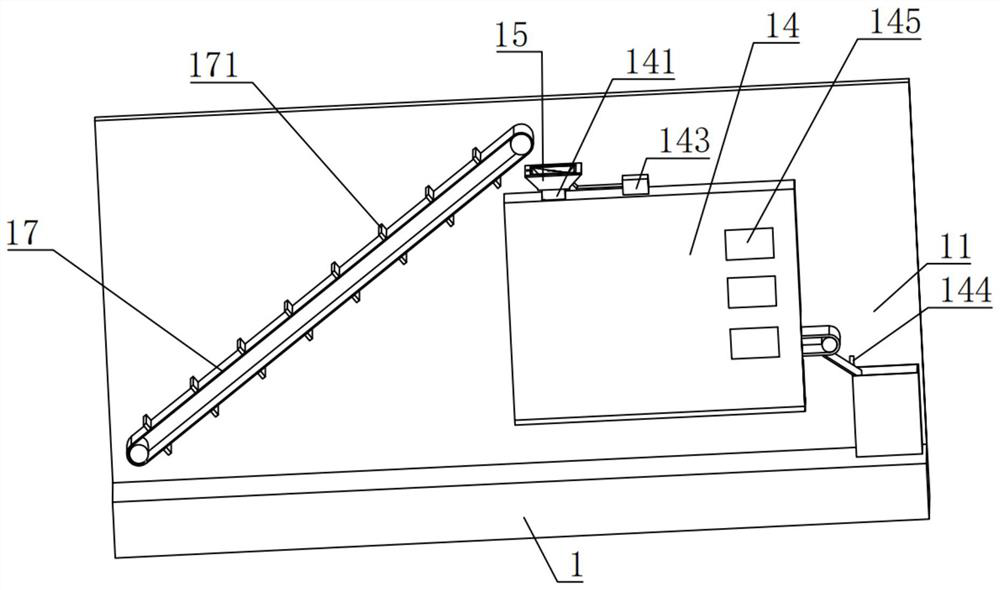

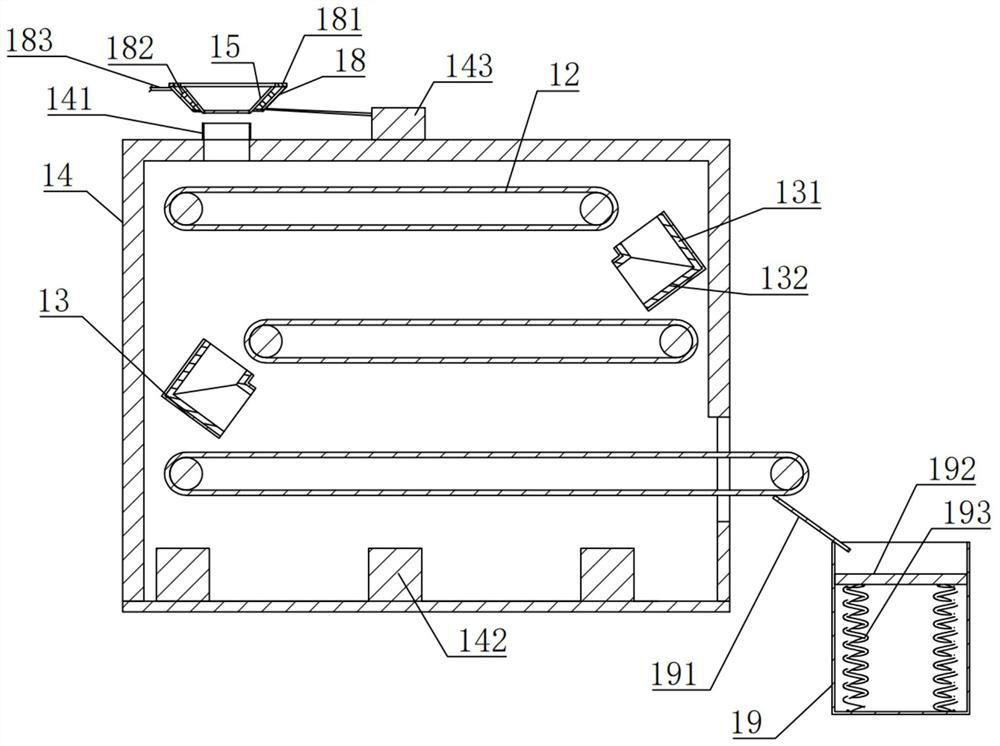

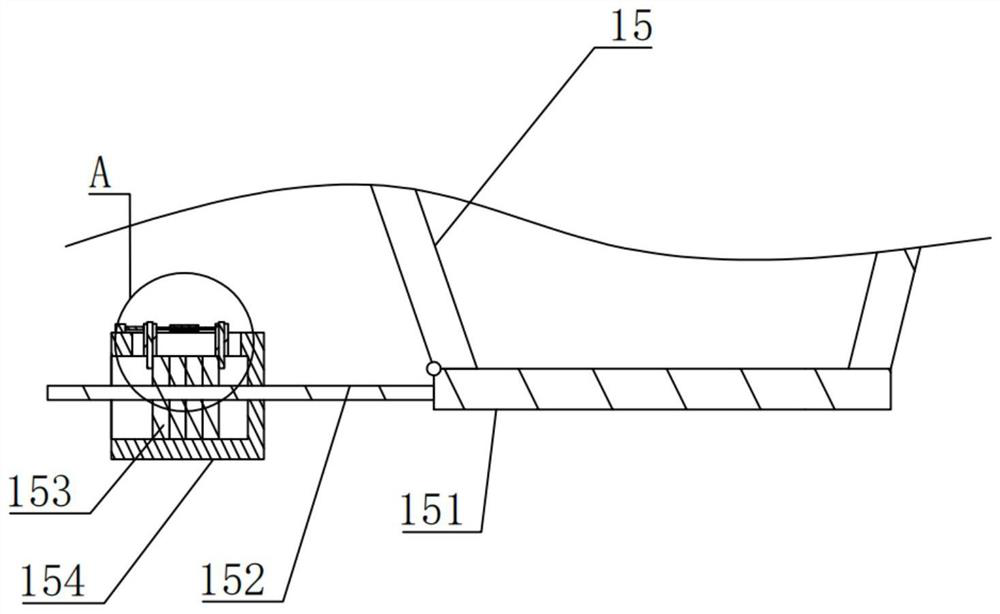

[0032] Embodiment: a kind of 2,5-dianilino terephthalic acid production drying device, such as figure 1 with figure 2 , comprising a base 1 placed on the ground, the upper end of the base 1 is provided with a vertical plate 11, and the vertical plate 11 is provided with a multi-layer mesh conveyor belt 12 parallel to each other, and the conveyor belts 12 of each layer are driven by a motor; at this time, each layer of transmission The belts 12 are all fixed on the vertical plate 11 by two rotating shafts, the rotating shaft is connected with the vertical plate 11 in rotation, and one of the rotating shafts is driven by a motor to rotate, and the transmission belt 12 is wound outside the two rotating shafts, because the transmission of the transmission belt 12 is a prior art , which will not be described here.

[0033] Such as figure 1 with figure 2 , one side of the base 1 is provided with a feeding part for transferring the product to the uppermost conveyor belt 12, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap