An environmentally friendly waste gas treatment equipment based on high-voltage electrostatic dust removal

A kind of exhaust gas treatment equipment and high-voltage electrostatic technology, which is applied in the field of electrostatic dust removal, can solve the problems of reducing dust removal efficiency, corona sealing of dust accumulation, poor effect of dust removal and so on, and achieve the effect of improving dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

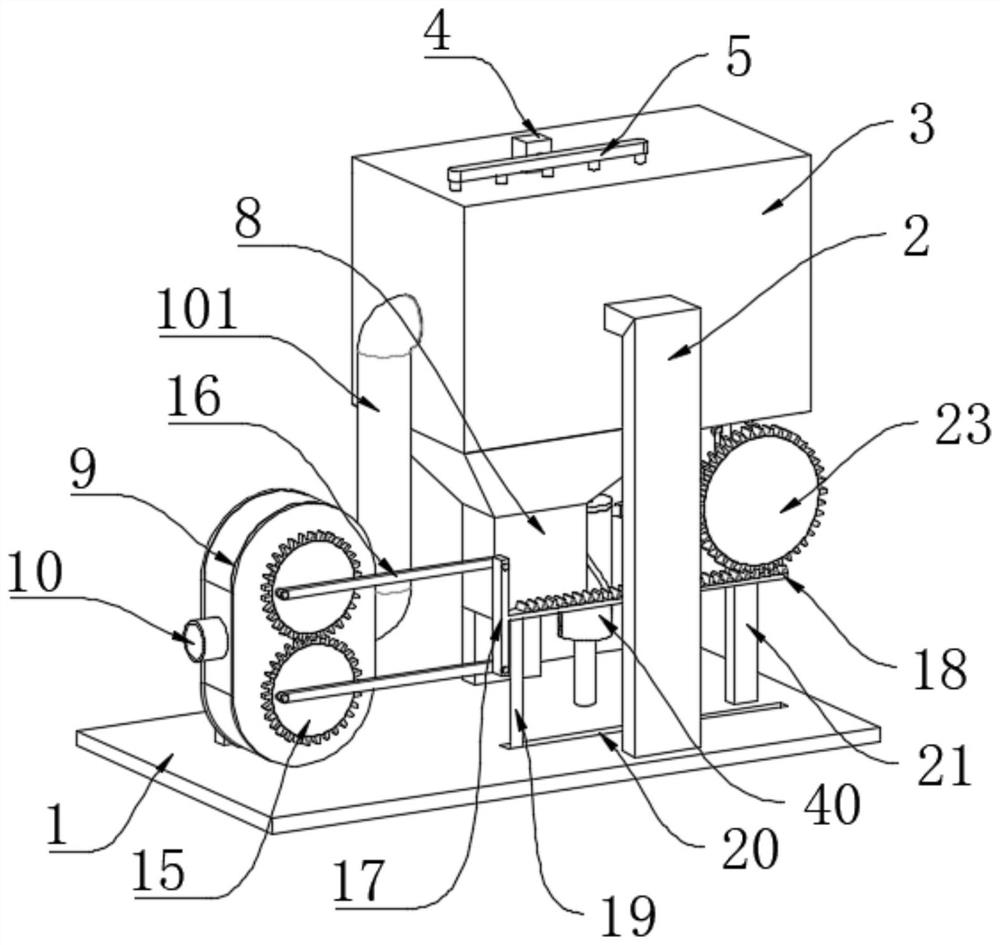

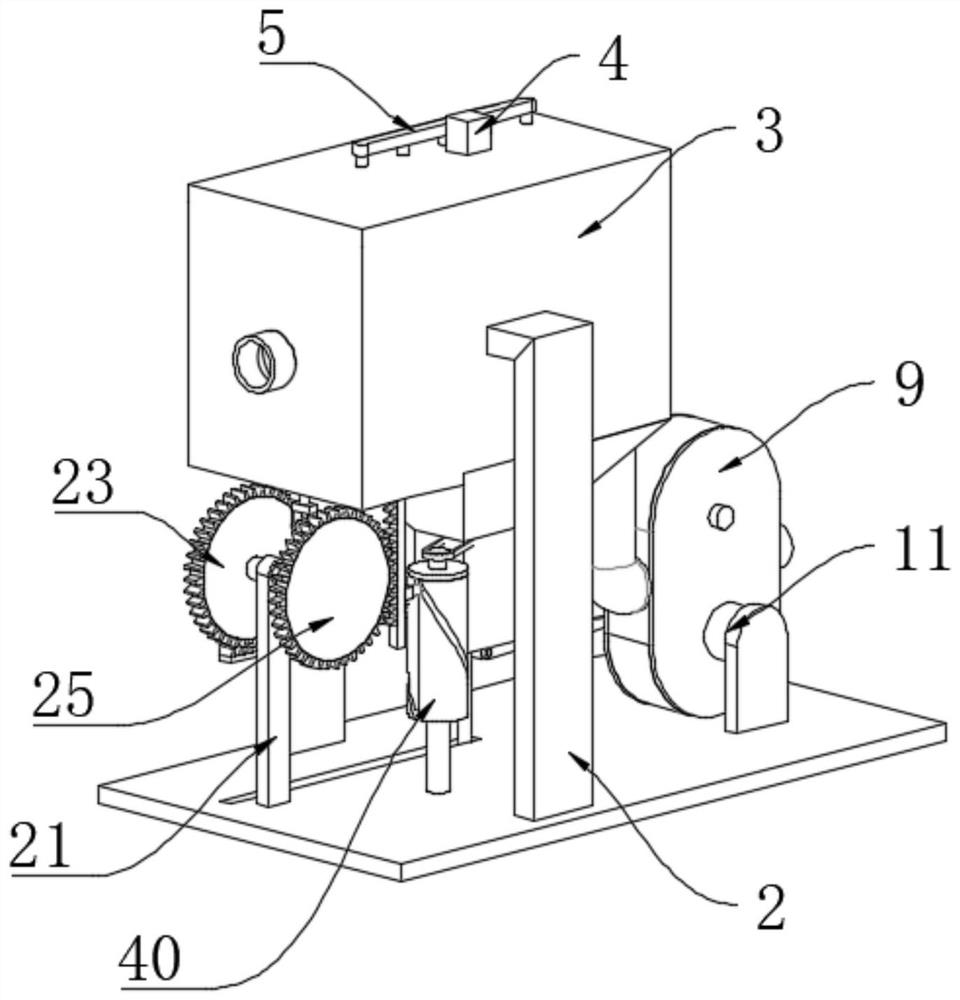

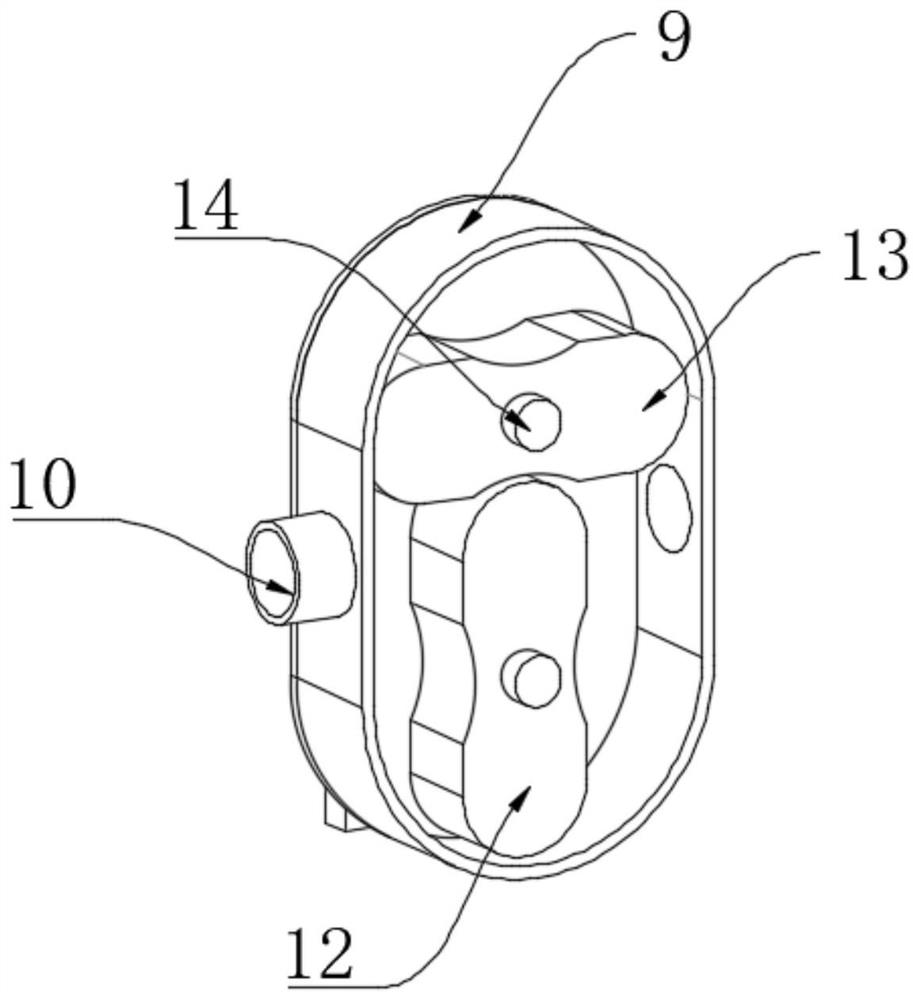

[0030] Such as figure 1 , image 3 , Figure 6 As shown, an environment-friendly waste gas treatment equipment based on high-voltage electrostatic precipitator includes a high-voltage power supply 4 that supplies power to the electrostatic precipitator system. The outer wall of the high-voltage power supply 4 is fixedly connected with a plugboard 5, and the bottom of the plugboard 5 is fixedly connected with a discharge electrode. Line 6, the bottom of the discharge electrode line 6 is fixedly connected with a drop weight 7, including an installation base plate 1, and the upper surface of the installation base plate 1 is fixedly connected with two sets of support plates 2 arranged vertically, and the opposite surfaces of the two sets of support plates 2 are fixed. The dust removal housing 3 is connected, the bottom of the dust removal housing 3 is fixedly connected with the discharge housing 8, and the upper surface of the installation bottom plate 1 is fixedly connected with...

Embodiment 2

[0047] Such as Figure 9 As shown, it is basically the same as Embodiment 1, the difference is that the inner cavity of the discharge housing 8 is provided with a dredging mechanism, and the dredging mechanism includes a fixed plate 42, and the fixed plate 42 is fixedly connected with the inner wall of the discharge housing 8, and fixed The bottom of plate 42 is rotatably connected with connecting shaft 43, and a belt 45 with a transmission effect is provided between the outer wall of connecting shaft 43 and the top of slide bar 39, and the outer wall of connecting shaft 43 is fixedly connected with stirring blade 2 46, stirring blade 2 46 is a zigzag blade, and the surface of the second stirring blade 46 is provided with through holes.

[0048] When the rotating drum 40 intermittently rotates in one direction, the transmission of the belt 45 drives the connecting shaft 43 to rotate synchronously, and then drives the stirring blade 2 46 to rotate to stir the accumulated dust i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com