Building stone processing equipment

A kind of processing equipment and construction technology, applied in the field of construction stone processing equipment, can solve the problems of large impact of stone, easy generation of dust, waste of equipment resources, etc., and achieve the effect of high strength, easy cleaning and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

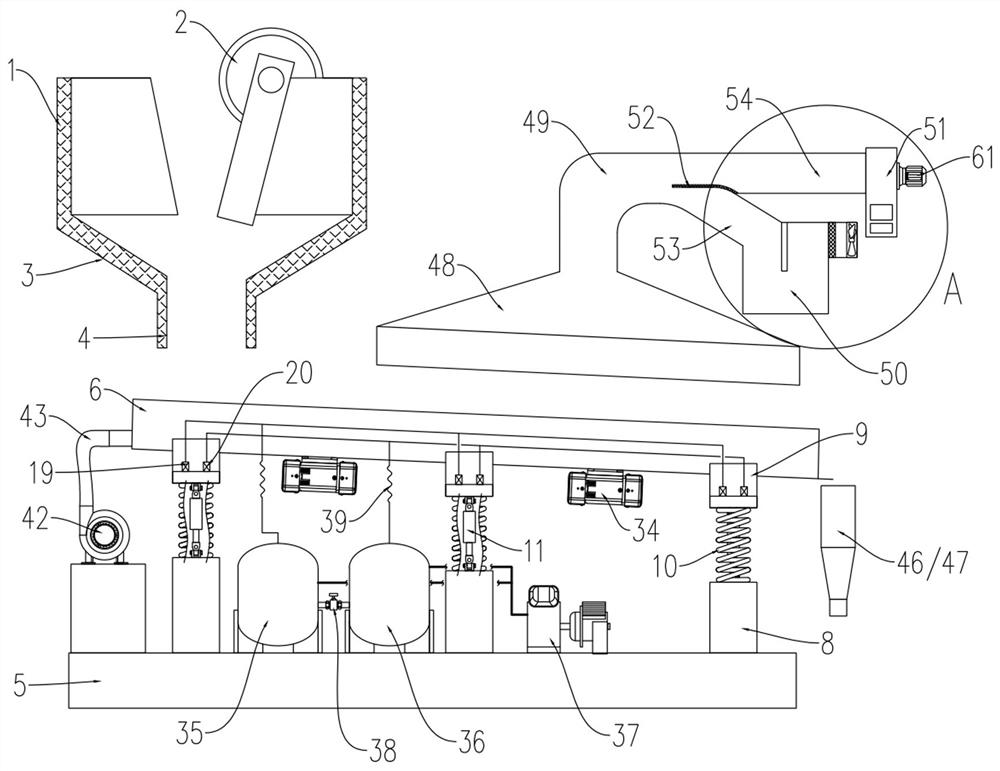

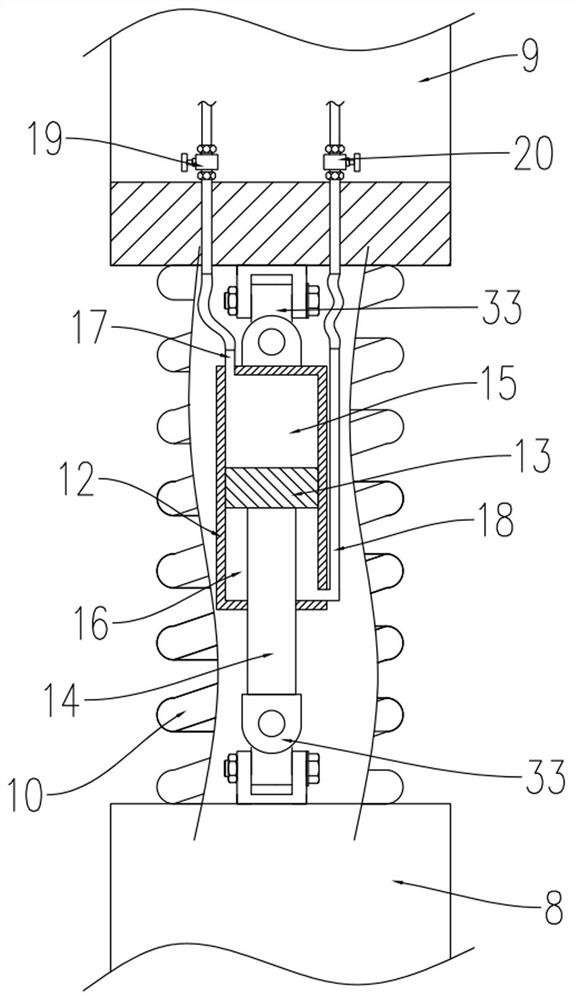

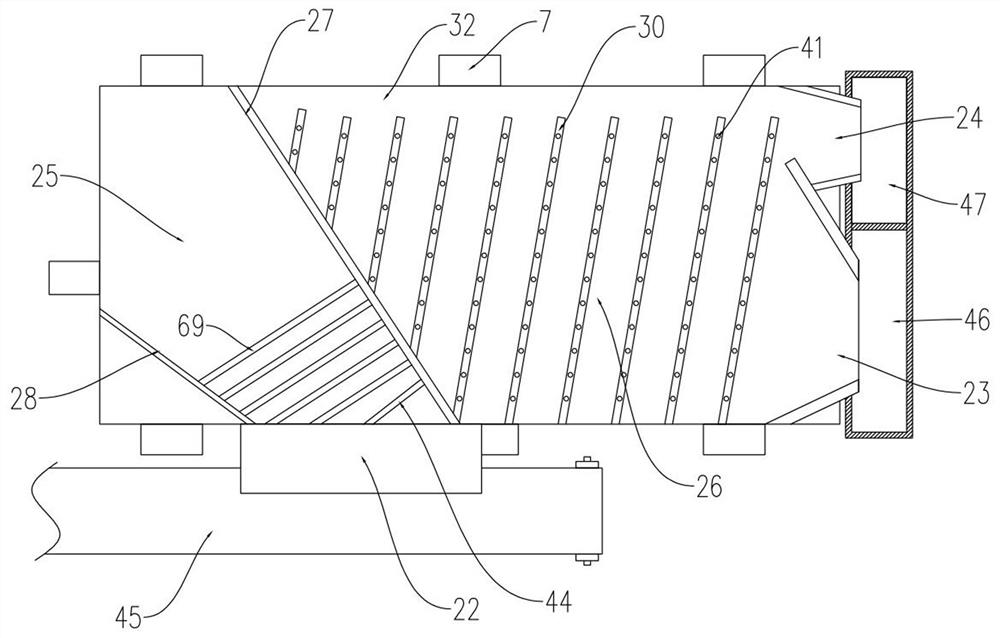

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, wherein the same components are denoted by the same reference numerals.

[0033] like figure 1 As shown, a stone processing equipment for construction includes a stone crushing device. The stone crushing device includes a feeding shell 1 and a crushing mechanism 2. The inside of the feeding shell 1 is provided with a crushing mechanism 2. The feeding shell 1 The crushing mechanism 2 provided in 1 is the prior art, and the structure disclosed in CN104624286B or CN104203413B can be adopted, and will not be repeated here. The bottom of the feed housing 1 has a conical lower hopper 3, and the lower hopper 3. The lower part is connected with the discharge port 4. After being crushed by the crushing mechanism 2, it flows out through the lower hopper 3 and the discharge port 4. The lower hopper 3 has the function of buffering and containing gravel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com