Nickel-based alloy powder and preparation method and application thereof

A nickel-based alloy and powder technology, applied in the field of nickel-based alloy powder and its preparation, can solve the problems of inability to meet large-scale production requirements, thermal cracking, and inhomogeneous ceramic particle heterogeneous nucleating agents, and eliminate the tendency of thermal cracking. , reducing microcracks, impurities and the effect of low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] In one or more embodiments of the present invention, the gas atomization device is used in the preparation of any nickel-based alloy powder and / or in the execution of any preparation method, and the application process includes:

[0049] Pour the nickel-based alloy powder of the matrix material and the composite ceramic particles of the reinforcement into the powder mixer;

[0050] Fill the powder mixer with inert gas, and discharge the air in the cavity of the powder mixer;

[0051] Start the powder mixer to obtain nickel-based alloy powder reinforced with inner composite ceramic particles.

[0052] Specifically, it includes: passing the inert gas at the set pressure into the powder mixer to remove the air in the cavity, then mixing the nickel-based alloy powder and the composite ceramic particles, and then mixing the outer coating of the ceramic reinforcement particles. The nickel-based alloy powder is poured into the crucible, heated and smelted, and the molten allo...

Embodiment 1

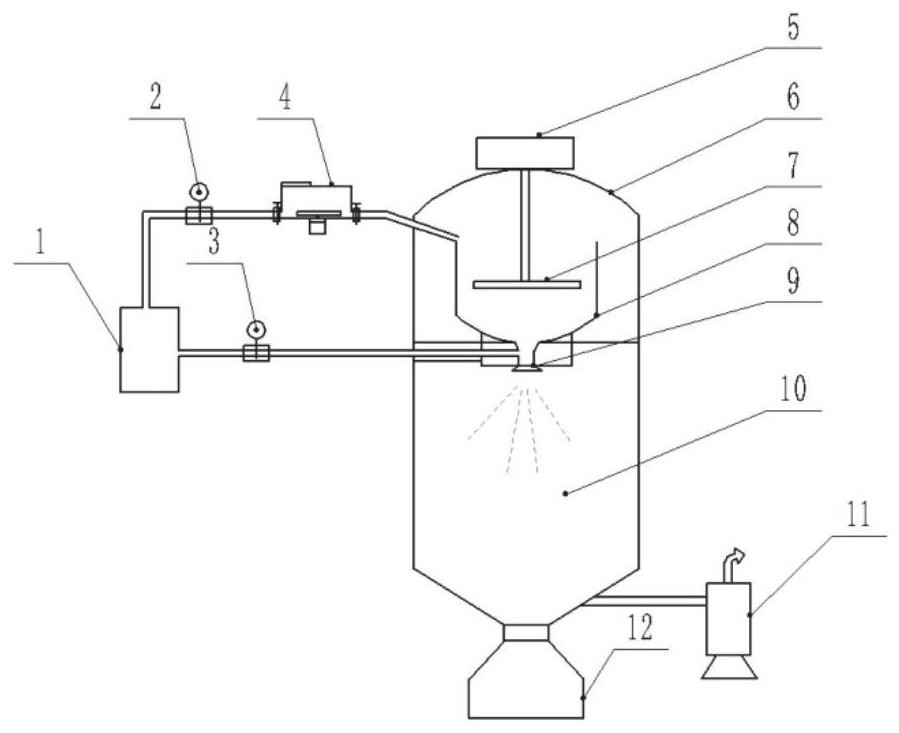

[0056] A gas atomization device, the structure is: the atomization nozzle 9 of the gas atomization device is connected to the protective gas source 1 through a pipeline, the pipeline is also provided with a pressure regulating valve 3, and the crucible 8 of the gas atomization device is connected to the protective gas source 1 through the pipeline. One end of the powder mixer 4 is connected, and the other end of the powder mixer 4 is connected with the protective gas source 1 through a pipeline, and a pressure regulating valve 2 is also arranged on the pipeline. The pressure regulating valves on the two pipes are used to adjust the air flow and keep the air flow stable. At the same time, the protective gas discharges the air to avoid the generation of other impurities. Secondly, a stirring device 7 is provided in the smelting chamber 6 for stirring the materials in the crucible, and at the same time, a control panel 5 is connected with the stirring device for controlling the s...

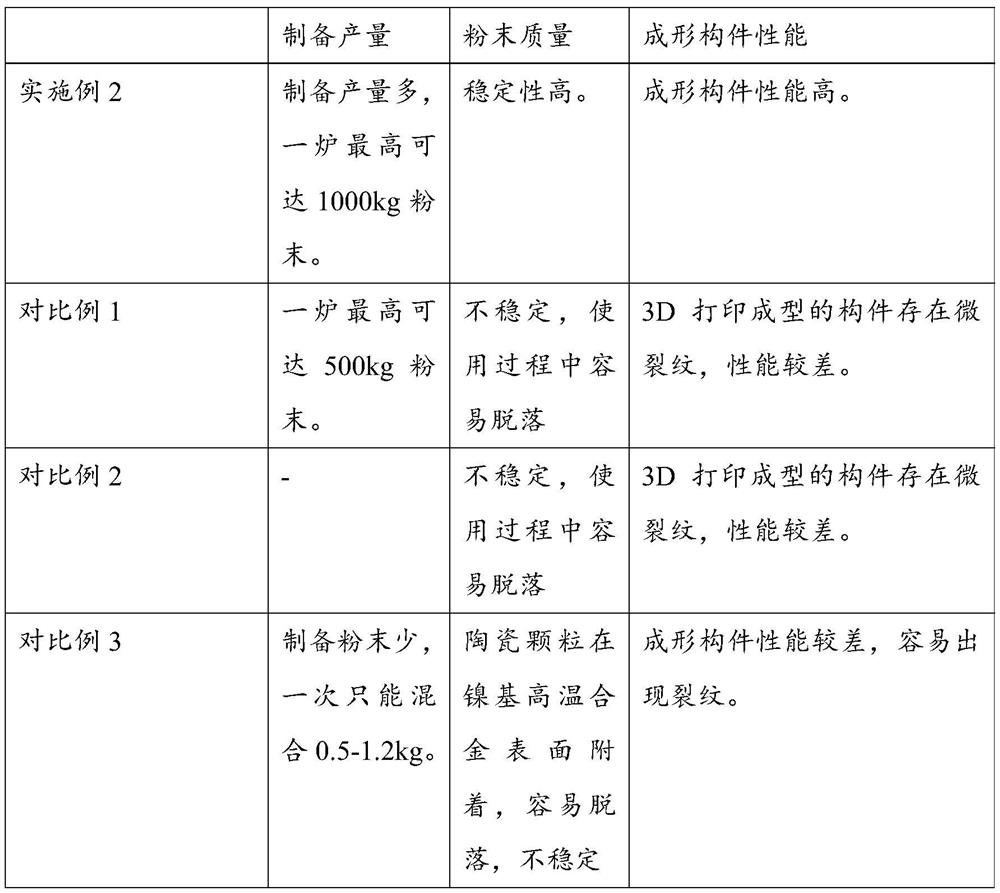

Embodiment 2

[0058] A nickel-based alloy powder, the specific preparation method is as follows:

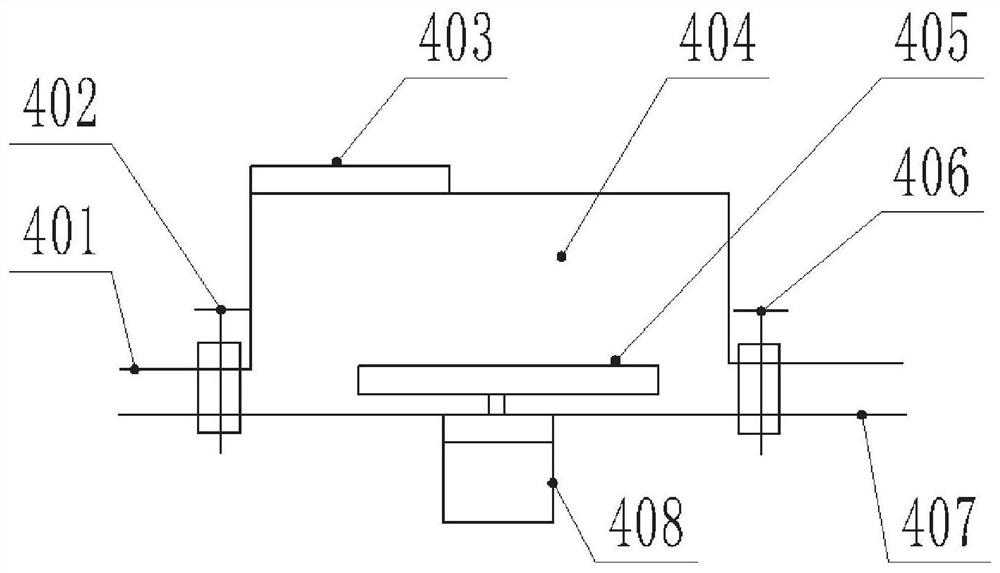

[0059] The preparation method is a vacuum induction gas atomization method, and the equipment used is a vacuum induction gas atomization device. As shown in Example 1, the vacuum induction gas atomization device includes a powder mixer 4, and the powder mixer device has an air inlet Channel, switch 1, control panel, helical blade, motor, switch 2, and air outlet channel. When vacuum induction gas atomization powder making, first pour the matrix GH3230 powder with a mass fraction of 99% and the mass fraction of GH3230 into the powder mixer. 1% TiB 2 and TiC composite ceramic particles, and then open the switch 1 and switch 2 of the pressure regulating valve 3 and the powder mixer 4, pass in the argon gas of the set pressure, discharge the air inside the powder mixer cavity 404, and then close the pressure regulation Valve 3 and switches 1, 2, start the control panel 403 of the powder mixer, ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com