Visual biological membrane culture reactor and in-situ observation method

A technology for cultivating reactors and biofilms, applied in bioreactor/fermenter combinations, specific-purpose bioreactor/fermenter, chemical instruments and methods, etc., can solve the inconvenience of in-situ sampling and the inability to realize real-time visual observation and other issues, to achieve the effect of buffer protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

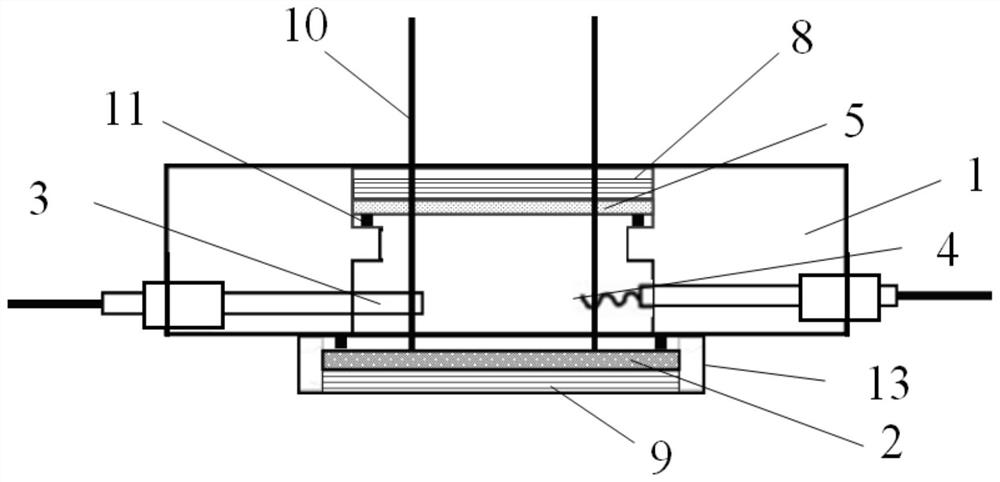

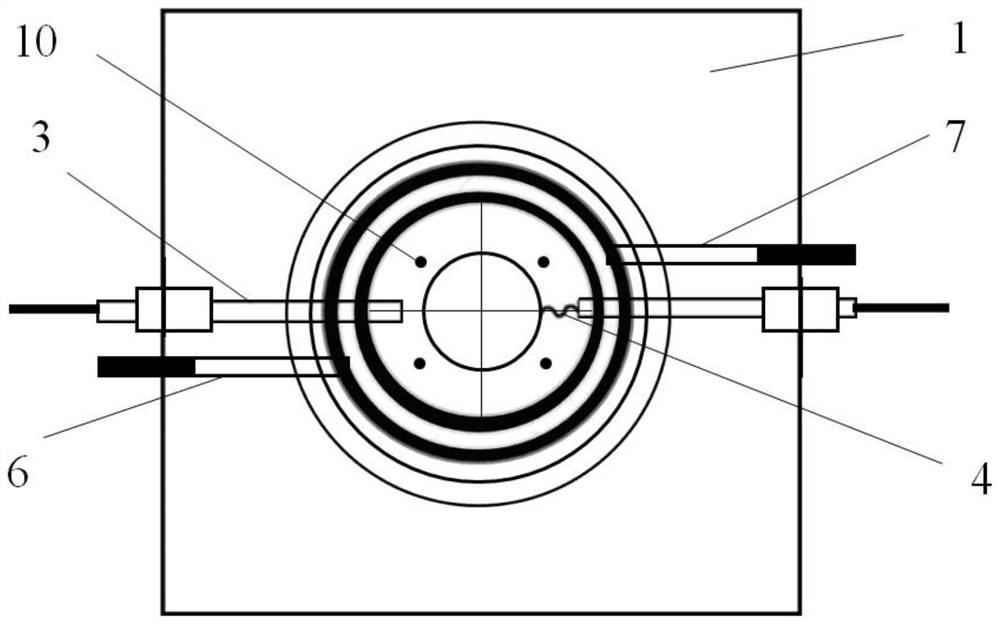

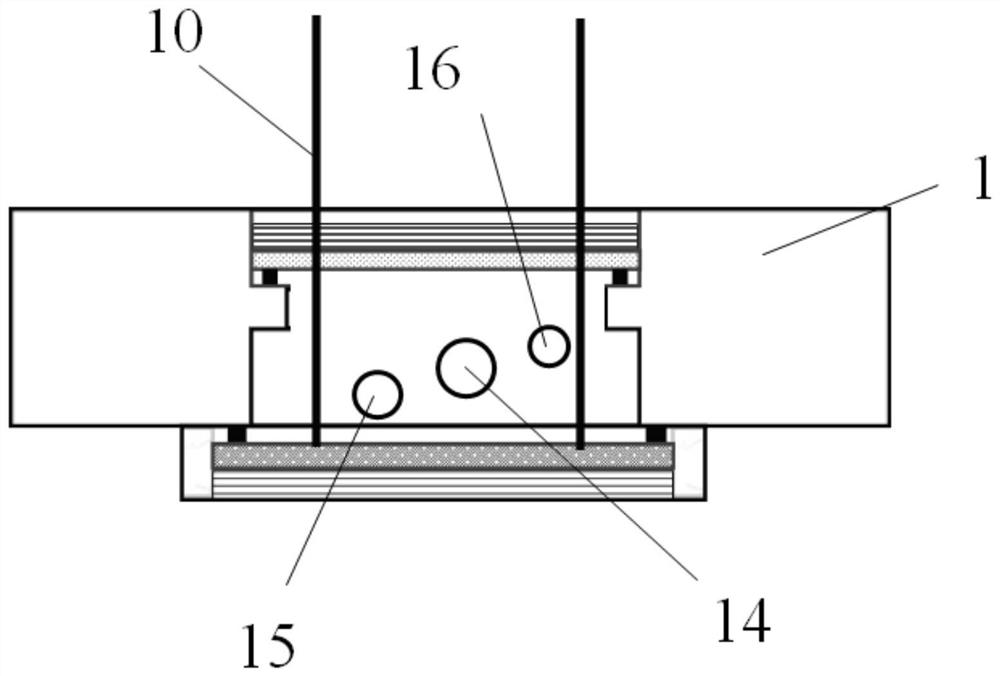

[0075] A visualized biofilm culture reactor, such as Figure 1 ~ Figure 4 As shown, the reactor body, reference electrode 3 and counter electrode 4 are included, the reactor body has a reaction chamber, and the side wall of the reactor body has a water inlet 15 and a water outlet 16 communicating with the reaction chamber and the outside, The water inlet 15 is installed with the water inlet pipe joint 6, and the water outlet 16 is equipped with the water outlet pipe joint 7, and the joints are all sealed. The side wall of the reactor main body is also provided with an electrode slot 14, and the reference electrode 3 and the counter electrode 4 pass through the reaction. The electrode socket 14 on the side wall of the device main body extends into the reaction chamber.

[0076] The main body of the reactor includes a body 1, a light-transmitting bottom plate 2, a cover 5, an upper fastening ring 8, a lower fastening ring 9, a conductive probe 10, a sealing gasket 11 and a clamp...

Embodiment 2

[0094] The transparent bottom plate is made of transparent glass whose inner surface is a conductive surface, and the conductive surface is used as a working electrode, which is connected to the electrochemical workstation through a conductive probe. Such as Figure 5 and Figure 6 As shown, one conductive probe 10 is provided, which passes through the body 1 and is detachably connected to the inner surface of the transparent bottom plate. The structure of the conductive probe is as Figure 8 As shown, the solid pipe section is fixedly connected to the body 1 instead of the cover, and runs through the body from the second step formed by the through hole and the hollow cavity.

[0095] Except for the light-transmitting bottom plate and the conductive probes, other settings are the same as those in Embodiment 1, and will not be repeated here.

[0096] A kind of application example corresponding to this embodiment 2:

[0097] The specific size settings are as follows:

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com