Control method and system for direct-drive permanent magnet hydroelectric generation system on basis of fuzzy control, terminal and readable storage medium

A technology of fuzzy control and control method, applied in control systems, hydroelectric power generation, control generators, etc., can solve the problems of long optimization time, oscillation, and cumbersome accuracy, so as to reduce tracking time, reduce energy loss, improve The effect of tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The focus of this embodiment is to use the fuzzy controller to realize maximum power tracking. The fuzzy controller constructed in this embodiment will be described below.

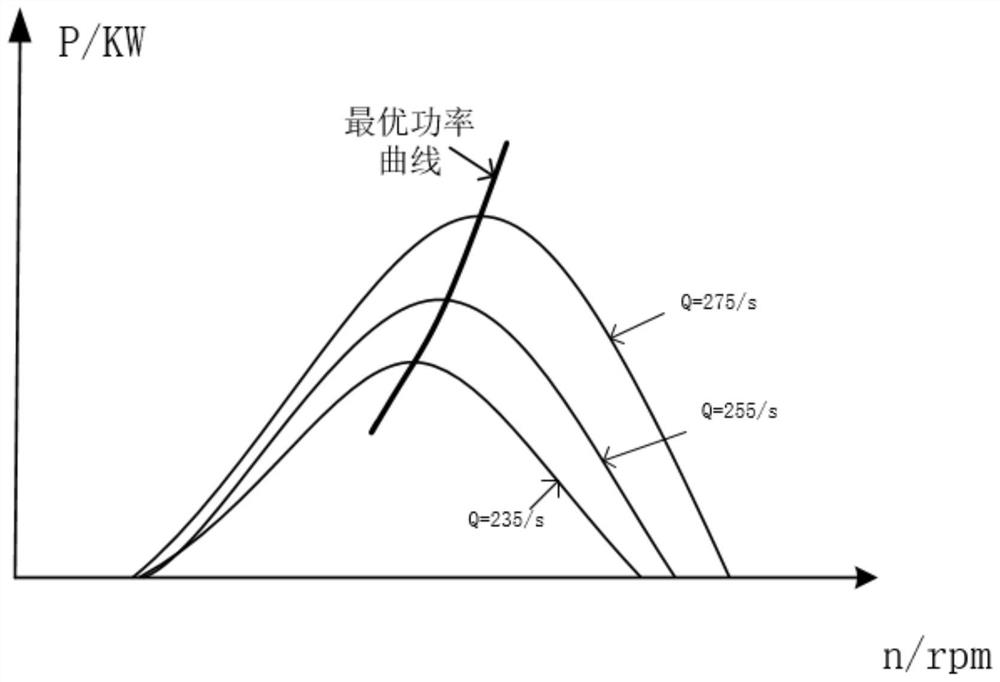

[0063] For a certain flow rate, the speed-power curve of the turbine is an approximate parabola, and the unique maximum power point is tracked by continuously changing the speed of the turbine. Therefore, the fuzzy controller constructed in this embodiment is a two-dimensional fuzzy controller. The input data of the fuzzy controller are the power variation Pe within the sampling time T and the rotational speed variation Sn-1 at the previous moment. The output data of the fuzzy control is The amount of speed change Sn at the current moment. Compared with the perturbation and observation method, using the fuzzy controller can change the speed step size in real time, and can speed up the tracking speed and reduce the steady-state oscillation at the maximum power point in the non-optimal operating regi...

Embodiment 2

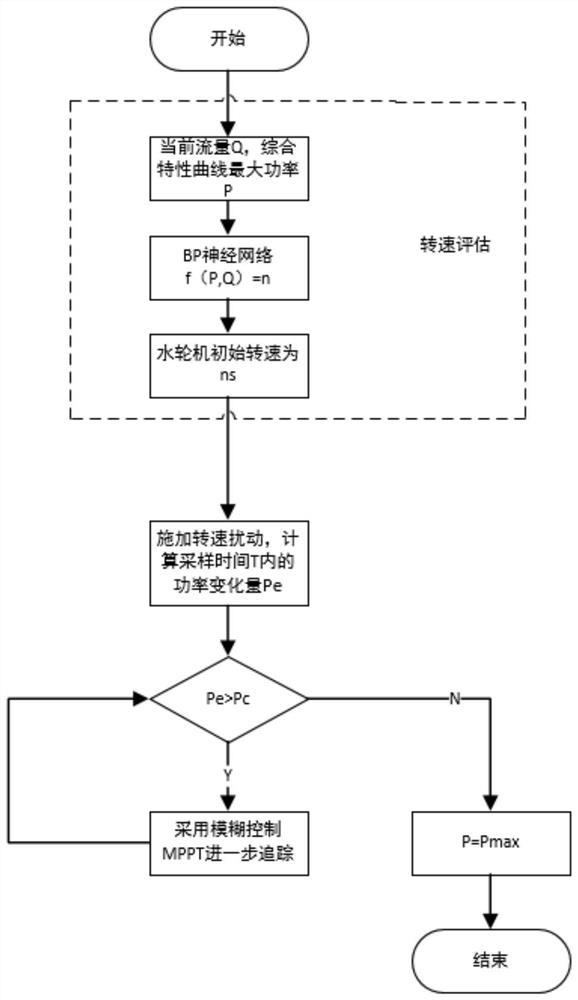

[0077] Such as figure 1 As shown, in this embodiment, neural network and fuzzy control are combined to improve tracking efficiency and accuracy. The fuzzy control-based direct-drive permanent magnet hydroelectric power generation system control method provided in Embodiment 2 includes:

[0078] S1-1: Input the flow Q and power P of the water turbine into the neural network to predict the initial speed of the water turbine, wherein the neural network uses the comprehensive characteristic curve power P and flow Q of the water turbine as the training input data, and the speed n as the training output data and obtained through network training. Since the comprehensive characteristic curve data of the water turbine is used as the training data, the trained model can be approximated as the speed-power curve of the current water turbine, so the output speed n of the neural network is not necessarily the optimal speed of the actual water turbine operation, but in the most In the ran...

Embodiment 3

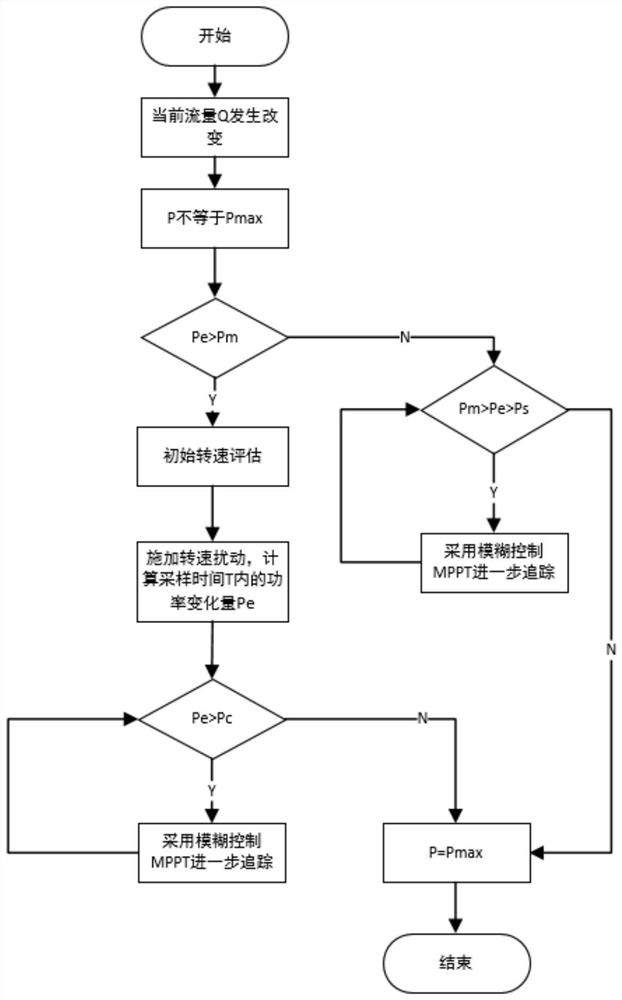

[0090] Such as figure 2 As shown, in this embodiment, it is considered that in actual working conditions, with the influence of weather or seasons, the flow rate that is easy to cause changes, therefore, this embodiment 3 provides a fuzzy control-based direct-drive permanent magnet hydropower system control The method is applied to the working condition of the variable flow rate of the water turbine, and the control method includes:

[0091] S2-1: Collect the power and calculate the variation Pe. If Pm>Pe>Ps, it means that due to the influence of weather or seasons, the flow Q changes greatly and the turbine deviates from the optimal speed. Step S2-2 is performed; if PcPm, the change of flow Q is large, and the current speed is far from the optimal speed, go to step S2-4. Among them, Pm and Ps are variable thresholds set for the power difference generated when the flow rate changes while the speed remains unchanged. That is, the power change threshold set based on this worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com