Bushing suitable for gas turbine transmission box body test and installation method thereof

A transmission box and gas turbine technology, applied in the transmission box test field, can solve the problems of high cost of test bench construction and influence on test results, etc., and achieve the effects of precise oil control, stable bearing lubrication, and sufficient oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

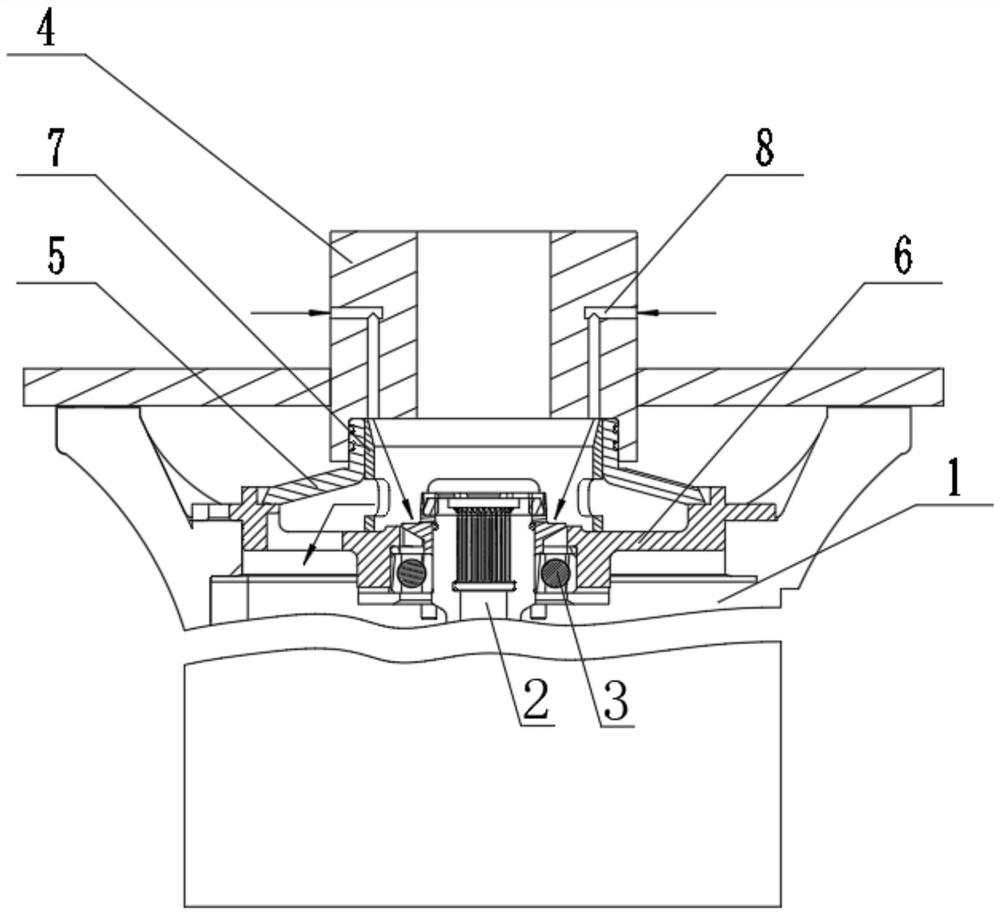

[0039] like Figure 1-Figure 3 As shown, the bushing suitable for the gas turbine transmission box test in this embodiment is equipped with a transmission box 1, a drive shaft 2 is arranged inside the transmission box 1, and a limited oil supply assembly is provided at the mouth of the transmission box 1.

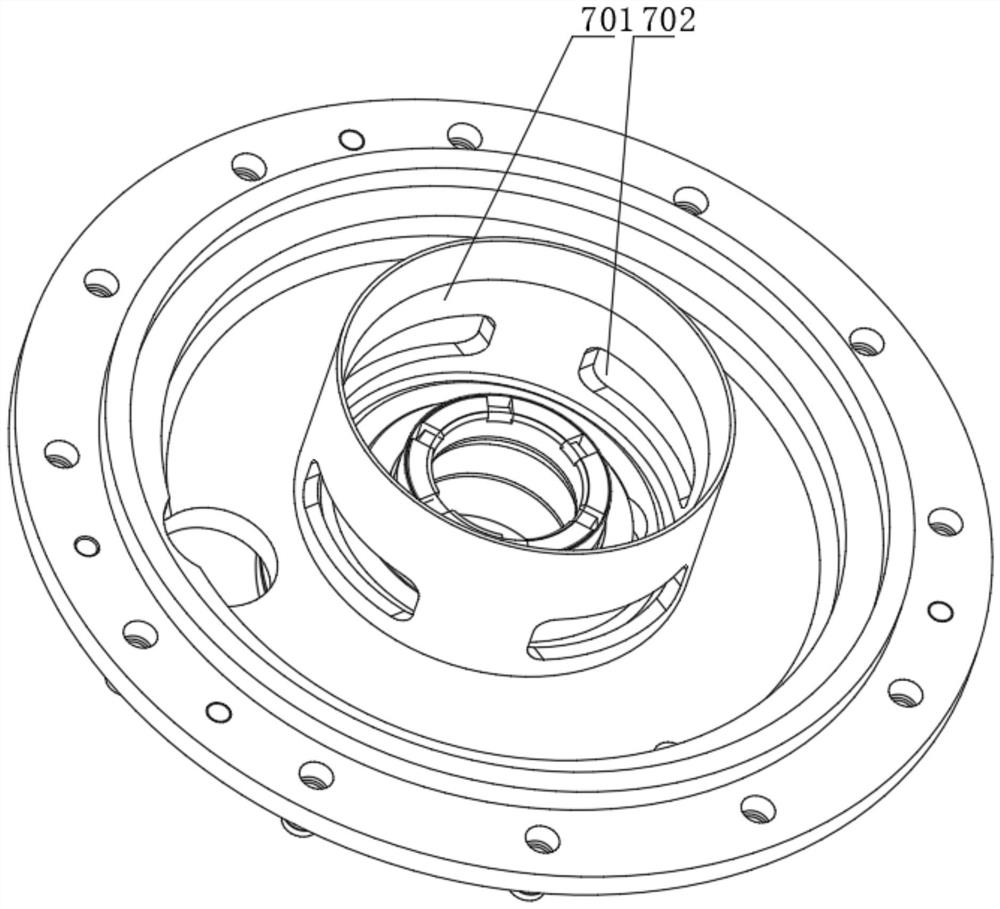

[0040] The limited oil supply assembly includes: the top bobbin 4, the top transition section 5 connected to the end of the top bobbin 4 extending into the transmission case 1, the shaft end cover 6 connected to the side of the top transition section 5 away from the top bobbin 4, the shaft The end cover 6 is coaxially sleeved on the drive shaft 2; the oil-accumulating bushing 7 is coaxially arranged in the top transition section 5,

[0041] The oil-accumulating bushing 7 includes a housing 701, an overflow hole 702 provided on the hous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com