Intelligent TEC temperature control circuit

A technology of temperature control and voltage control circuit, which is applied in the direction of temperature control by electric method, auxiliary controller with auxiliary heating device, etc., which can solve the problem of high requirements on digital processing capability of single-chip microcomputer, complicated circuit debugging and short development cycle, etc. problem, to achieve the effect of simple structure, low cost and stable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

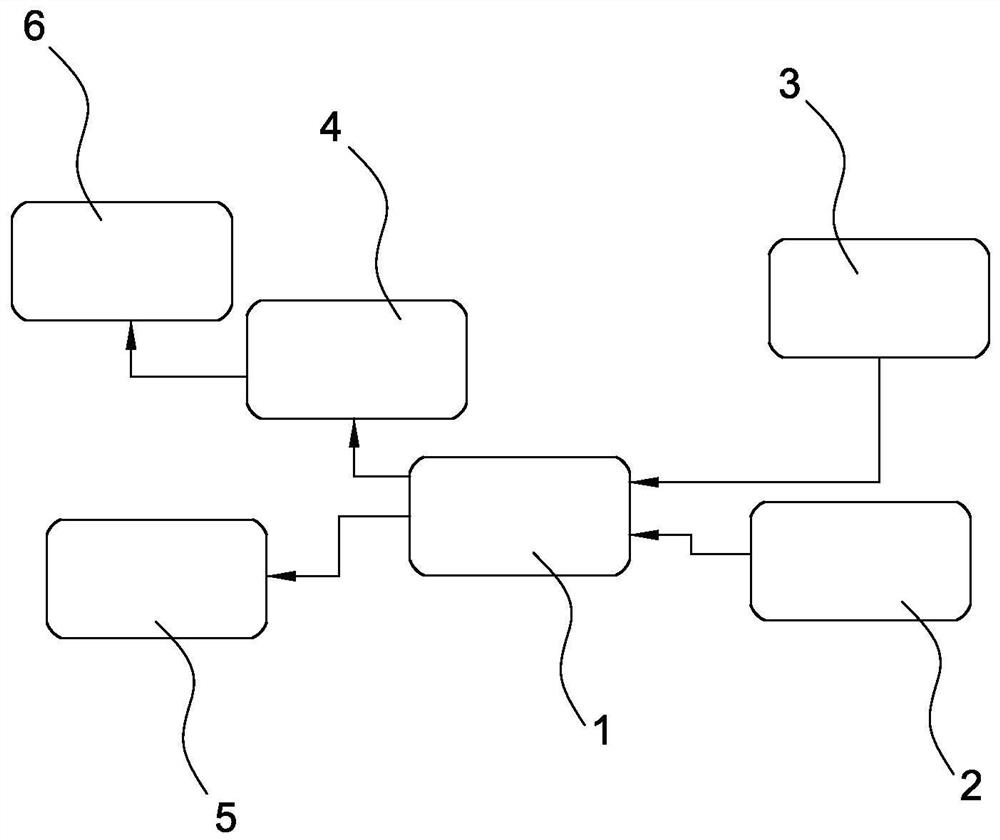

[0021] Embodiment one: see figure 1 As shown, an intelligent TEC temperature control circuit includes a single-chip main control circuit 1 connected to the TEC, a temperature acquisition circuit 2, a current sampling circuit 3, a voltage control circuit 4, an H bridge 5 and a switching power supply 6,

[0022] The temperature collection circuit is used to collect the working temperature of the TEC;

[0023] The current collection circuit is used to collect the working current of the TEC;

[0024] The voltage control circuit is used to set the voltage of the switching power supply;

[0025] The switching power supply outputs the operating voltage of the TEC to the H-bridge;

[0026] The H-bridge is used to control the switching of TEC heating or cooling under the control of the main control circuit of the single-chip microcomputer;

[0027] The single-chip main control circuit is used to analyze and process the data collected by the temperature acquisition circuit and the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com