Roller kiln firing zone temperature prediction method based on mechanism and data hybrid driving

A hybrid drive and prediction method technology, applied in special data processing applications, computer-aided design, design optimization/simulation, etc., can solve problems such as lack of robustness, data-driven modeling that cannot describe the kiln mechanism process, etc. , to achieve the effect of ensuring the effectiveness of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

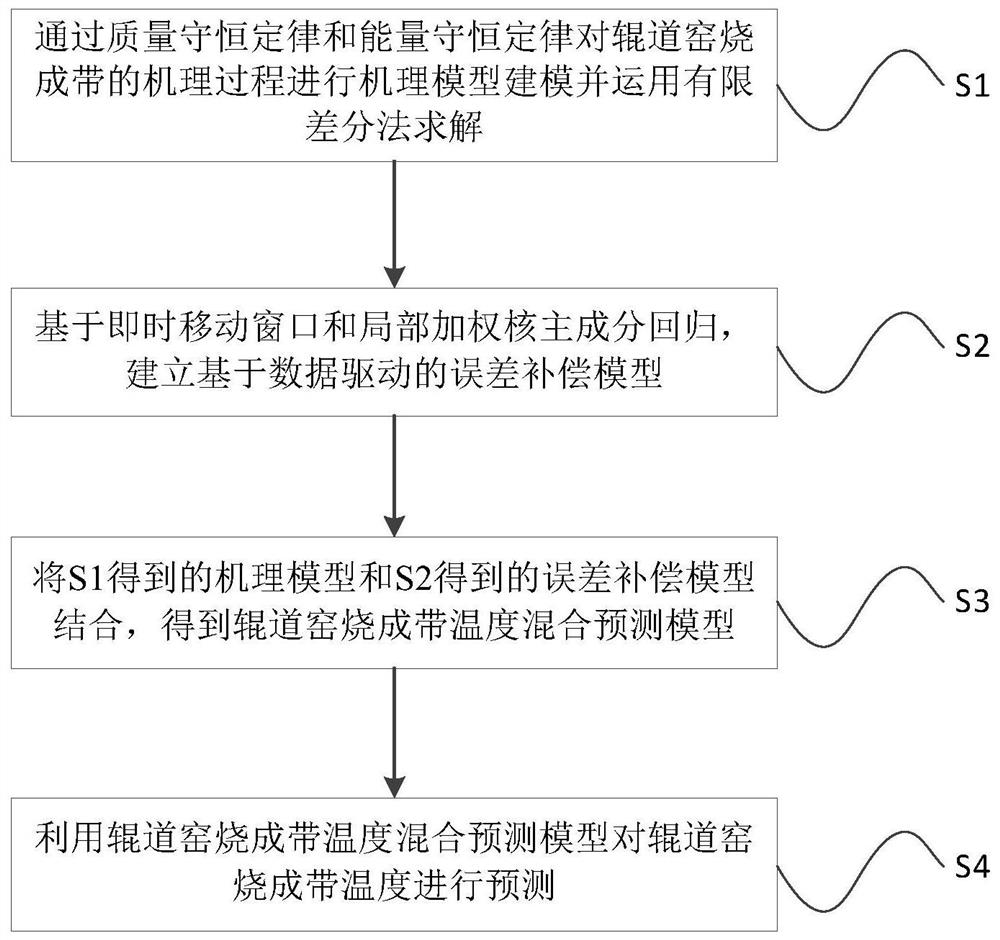

[0130] This embodiment provides a method for predicting the temperature of the firing zone of a roller kiln based on a combination of mechanism and data, such as figure 1 shown, including:

[0131] S1: Model the mechanism model of the firing zone of the roller kiln through the law of mass conservation and energy conservation and use the finite difference method to solve it;

[0132] S2: Establish a data-driven error compensation model based on instant moving windows and locally weighted kernel principal component regression;

[0133] S3: Combine the mechanism model obtained in S1 and the error compensation model obtained in S2 to obtain a mixed prediction model for the temperature in the firing zone of the roller kiln;

[0134] S4: Predict the temperature of the firing zone of the roller kiln by using the mixed prediction model of the firing zone temperature of the roller kiln.

[0135] Preferably, the step S1 specifically includes the following steps:

[0136] S1.1: Analyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com