Laminated packaging structure for mounting multiple circuit boards

A stacked packaging, multi-circuit technology, applied in the structural connection of printed circuits, printed circuits, and support structure installation, etc., can solve the problems of difficult protection, easy damage to the circuit board, affecting the working efficiency of the chip, etc., to reduce the occupied space, strong Thermal conductivity, the effect of convenient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

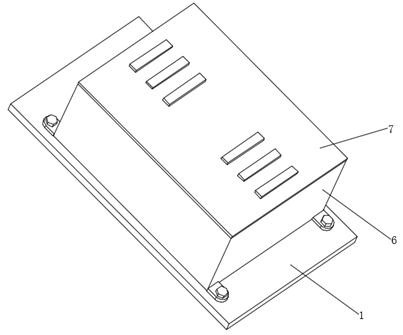

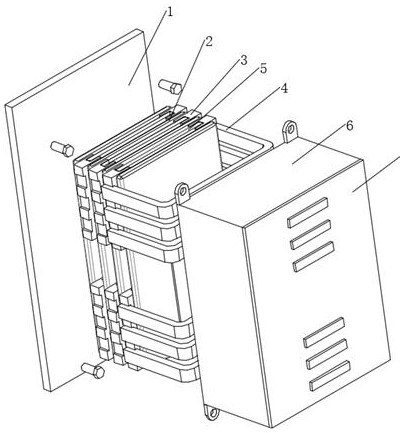

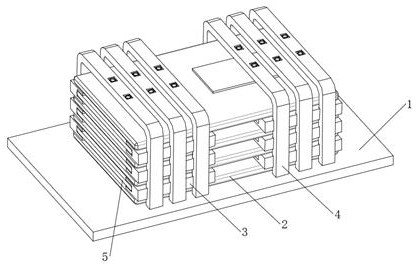

[0042] see Figure 1-6, a stacked packaging structure for multi-circuit board installation, including a mounting board 1, a plurality of evenly distributed printed circuit board bodies 2 are arranged on the mounting board 1, and a heat conducting plate 201 is fixedly connected to the bottom end of the printed circuit board body 2 , the heat conduction plate 201 is laid with a heat conduction film, and the printed circuit board main body 2 is provided with a plurality of pairs of positioning mounting holes matching the buffer shelf plate 3, so that the printed circuit board main body is clamped on the buffer shelf plate 3 through the heat conduction plate. Two pairs of buffer frame plates 3 are connected between two adjacent printed circuit board main bodies 2. The buffer frame plates 3 include an L-shaped frame plate 301. A buffer belt 5 and a hollow bag tube 501 are connected between a pair of L-shaped frame plates 301. The inner wall of the inner wall is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com