Dispersants made from isocyanates and amines

A technology of isocyanate and dispersant, applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., can solve the problems of dispersion system damage and failure to form absorption layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The preparation of embodiment 1 dispersant of the present invention

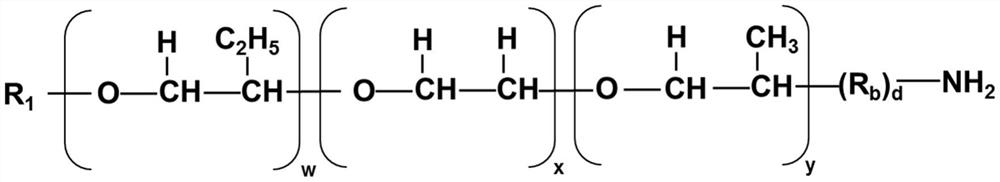

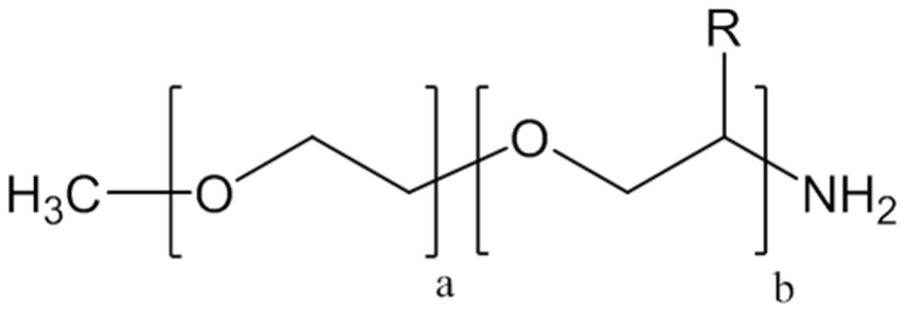

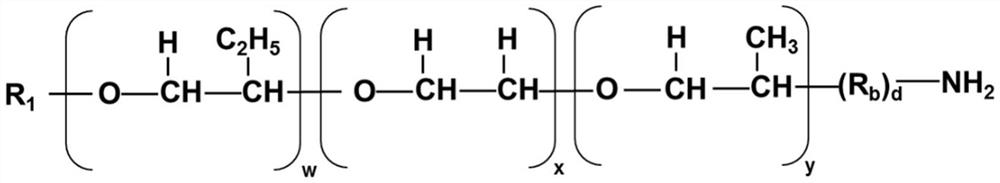

[0088] 69.9 grams (0.035 moles, 0.035 equivalents) of polyoxyalkylene monoamine ( L-200 amine) was heated to 50°C and added to a 250ml dry container. Then slowly add 5.0 grams (0.017 moles, 0.35 equivalents) of uretdione group-containing polyisocyanate compound ( 143L polyisocyanate). After all of the polyisocyanate compound had been added, the container was capped and the reaction mixture was allowed to mix for an additional 30 seconds. The container was then placed in an oven at 60°C for a period of time (14 hours).

[0089] Other polyoxyalkylene monoamines and isocyanate compounds are reacted as described above to form further dispersants of the present invention. Table 1 gives the combination of the monoamine and isocyanate compounds and the equivalent ratio of amine to isocyanate for each dispersant. The reaction was verified by measuring the amine number and isocyanate content of the disp...

Embodiment 2

[0093] Application of embodiment 2 dispersants

[0094] Preparation of Aqueous Medium / Dispersion Agent

[0095] An amount of each of the above dispersants was dissolved in an equal amount of water to form a 50wt% / 50wt% composition.

[0096] B. Preparation of Colorants

[0097] Pigment (20wt%), aqueous medium / dispersant A (5wt%) (or 1:10 active dispersant pigment) and additional water (75wt%) were premixed at 3000rpm using an accelerated mixer (FlackTek Speed Mixer) for 30 Second. 40 grams of this mixture were then mixed with 10 grams of 2 mm glass beads and ground for 3 minutes at 3000 rpm. The glass beads are then separated from the colorant.

[0098] C. Preparation of acceptable color paint

[0099] A white primer (PPG Olympic One Interior Semi-gloss Enamel (Base 1-356824)) was mixed with 1% of the blend prepared in A using the speed mixer described above for 3 minutes at 3000 rpm.

[0100] D. Test microfilm

[0101] Color Acceptable Paint C and Colorant B were mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com