Shortfall quantity liquid container

A liquid container and container technology, applied in the direction of biochemical instruments, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problems of increasing consumption and cost, and achieve high sterility and consumption Low, the effect of reducing the risk of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

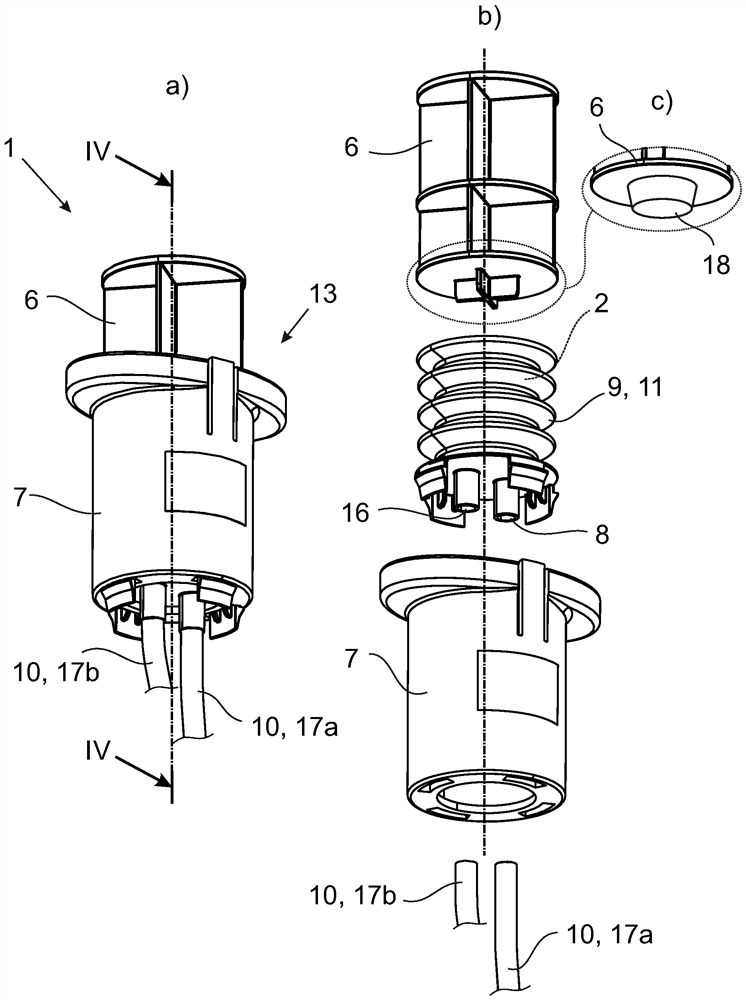

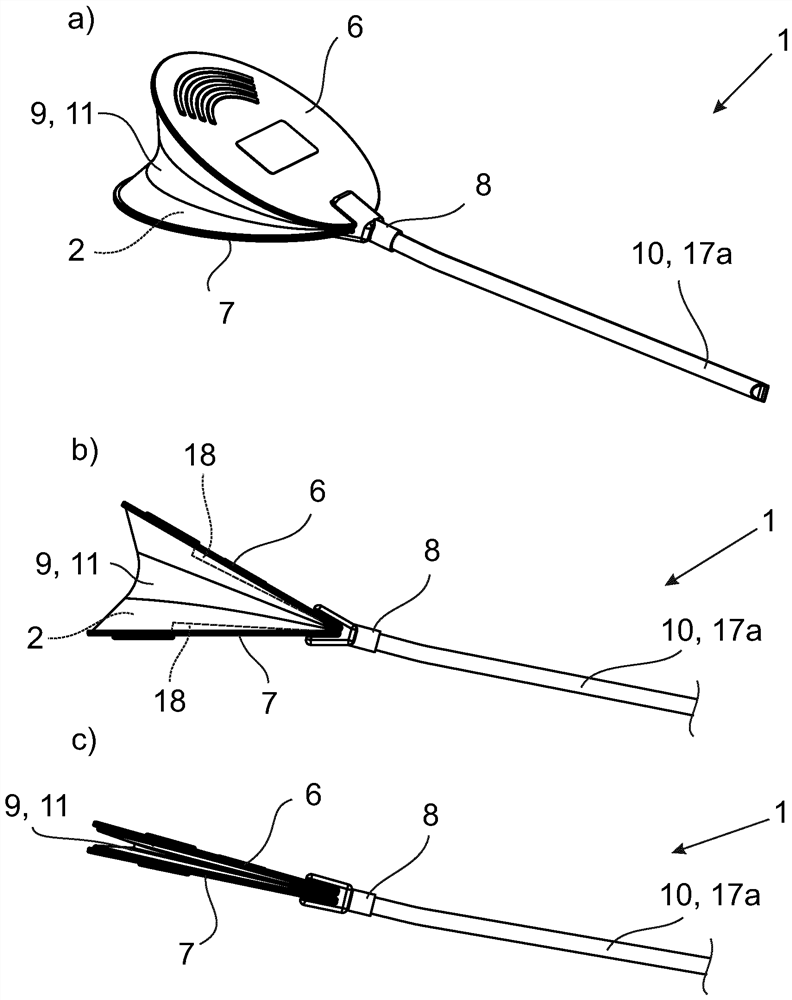

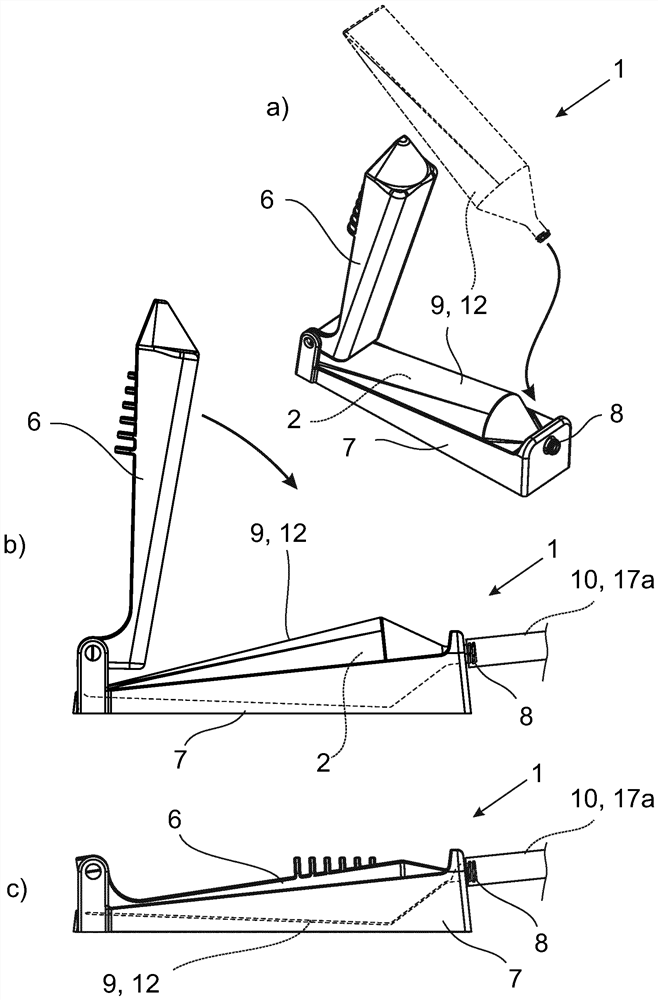

[0035] Figures 1 to 6 The volume reduction liquid container 1 according to the proposed solution shown in the various embodiments is used for outputting a liquid medium, here a biological medium, which is prefilled on the manufacturer's side, to a bioprocessing plant, in particular a bioreactor In the device, the bioprocessing equipment or the bioreactor forms a closed system or is integrated into a closed system. The bioreactor not shown here for the sake of clarity is designed, for example, as a laboratory bioreactor, i.e. as a bioreactor which, in contrast to a production bioreactor, has a relatively small volume of up to 10 liters. Working volume (maximum usable filling volume). Such bioreactors are used to carry out biotechnological processes, which are here and preferably used for the production of pharmaceutical agents (ATMPs) for novel therapies. For example a biotechnological process can also be a cell expansion process for T cells. In any event, a biological reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com