Processing method for reducing astringent taste of Longjing tea

A processing method, the technology of Longjing tea, applied in tea processing before extraction, food science, etc., can solve the problems of reducing Longjing tea, achieve the effects of reducing astringency, mellow taste, and reducing the content of tea polyphenols

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

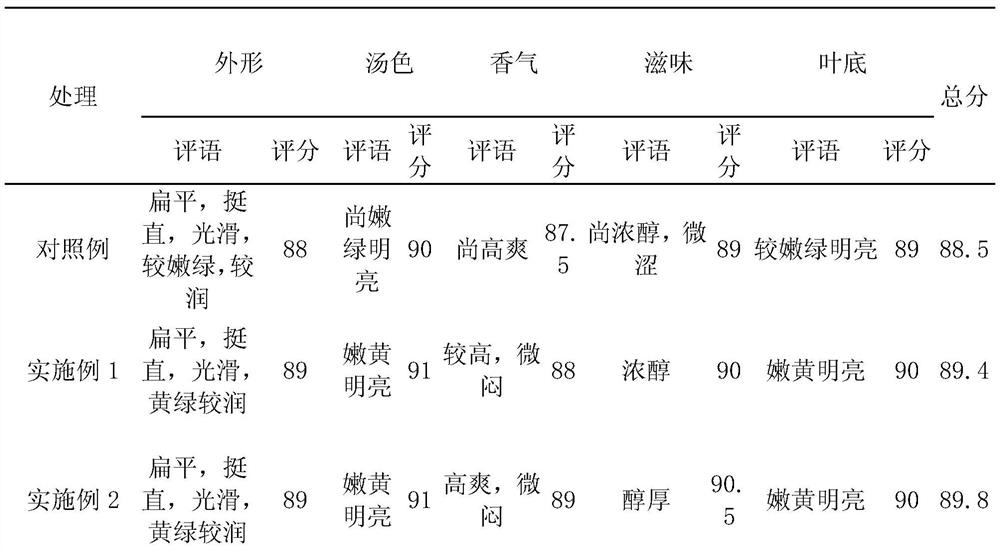

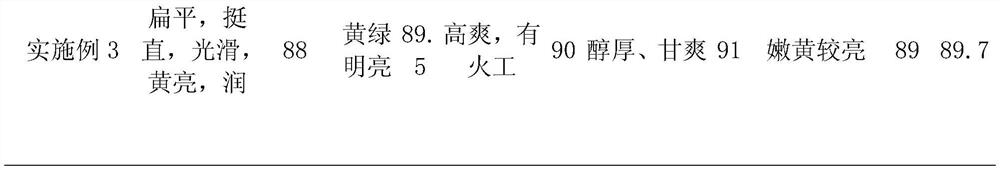

Examples

Embodiment 1

[0022] A processing method for reducing the astringent taste of Longjing tea, the specific steps are as follows: (1) Spreading: Pick fresh Longjing tea leaves with one bud and one leaf or one bud and two leaves, and place them on indoor bamboo plaques Stand still, avoid light and ventilate and spread for 4 hours; (2) Finishing: Use a flat tea frying machine to clean the fresh tea leaves. The finishing temperature is 200 ° C, and the finishing time is 2.5 minutes. The mesh cover set on the top of the pot is closed) for 2 minutes, in which the fresh leaves are stir-fried in the state of no pressure for 1 minute, and the fresh leaves are stirred in the state of light pressure for 1 minute, then the cover is opened and blown with a fan, in the state of medium pressure Stir-fry fresh Longjing tea leaves for 0.5 minutes; (3) Green pot shape treatment: use a flat tea frying machine at a temperature of 140°C for 8 minutes. The mesh cover is closed), stir-fry the fresh leaves under lig...

Embodiment 2

[0024] A processing method for reducing the astringent taste of Longjing tea, the specific steps are as follows: (1) Spreading: Pick fresh Longjing tea leaves with one bud and one leaf or one bud and two leaves, and place them on indoor bamboo plaques Stand still, avoid light and ventilate and spread for 6 hours; (2) Finishing: use a flat tea frying machine to clean the fresh tea leaves, the finishing temperature is 210°C, and the finishing time is 3 minutes. Close the mesh cover on the top of the pot) for 2 minutes, stir-fry the fresh leaves in the state of no pressure for 1 minute, stir-fry the fresh leaves in the state of light pressure for 1 minute, then open the cover, blow with a fan, and turn over in the state of medium pressure Stir-fry fresh Longjing tea leaves for 1 min; (3) Green pot for shape treatment: use a flat tea frying machine at a temperature of 150°C for 13 min, and first set a net-like shelter on the top of the pot (the net set on the top of the pot Close ...

Embodiment 3

[0026] A processing method for reducing the astringent taste of Longjing tea, the specific steps are as follows: (1) Spreading: Pick fresh Longjing tea leaves with one bud and one leaf or one bud and two leaves, and place them on indoor bamboo plaques Stand still, avoid light and ventilate and spread for 8 hours; (2) Finishing: use a flat tea frying machine to clean the fresh tea leaves, the finishing temperature is 220°C, and the finishing time is 4 minutes. Close the mesh cover above the pot body) for 3 minutes, stir-fry the fresh leaves in the state of no pressure for 1 minute, stir-fry the fresh leaves in the state of light pressure for 2 minutes, then open the cover, blow with a fan, and turn over in the state of medium pressure Stir-fry fresh Longjing tea leaves for 1 minute; (3) shape treatment in green pot: use a flat tea frying machine at a temperature of 160°C for 17 minutes, first set a mesh shield on the top of the pot (the mesh set above the pot Close the cover), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com