Composite potato chips with health-care function and making method of composite potato chips

A production method and technology of potato chips, applied in the functions of food ingredients, food science, applications, etc., can solve the problems of no health care function and poor taste of powder, and achieve good therapeutic effect, attractive color and crisp taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

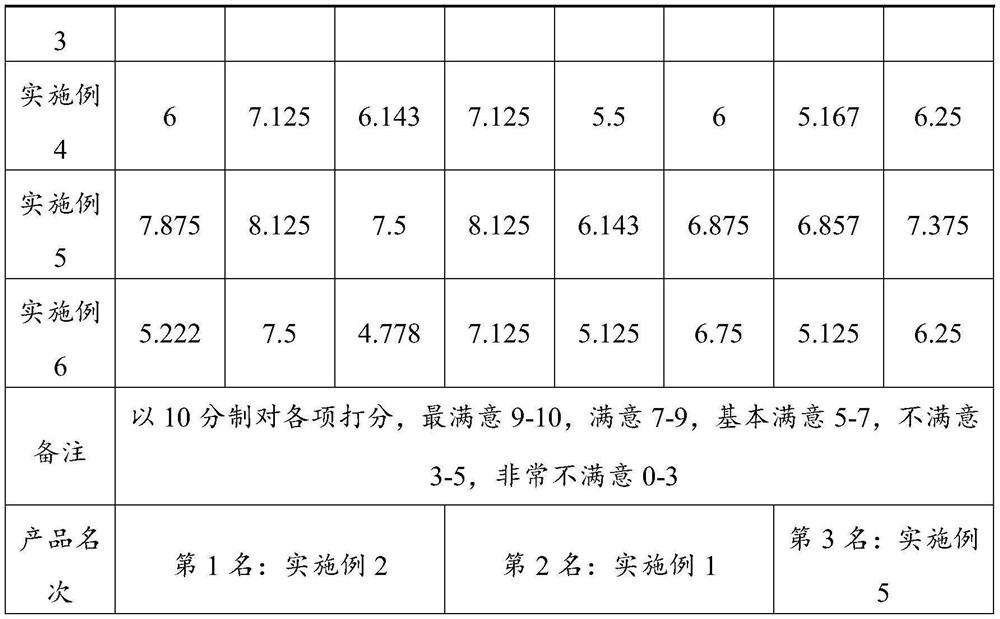

Examples

Embodiment 1

[0039] Weigh 50 parts of wheat flour, 15 parts of cornstarch, 15 parts of potato flour, 1 part of poria cocos powder, 2.5 parts of white granulated sugar, and 0.8 parts of edible salt, wherein the particle diameters of wheat flour, cornstarch, potato flour and poria cocos powder are all 30 mesh;

[0040] Wheat flour, potato flour and Poria cocos powder are fully mixed in a mixer to obtain mixed powder A;

[0041] Mix cornstarch, white sugar, and edible salt, and add warm water that is 1 times the total weight of cornstarch, white sugar, and edible salt, and stir until completely dissolved to obtain a mixed liquid material B;

[0042] Add the mixed liquid material B into the mixed powder material A, add water until the water content of the mixture is 25%, and obtain the mixed material C;

[0043] The mixed material C is compressed into tablets by two compression procedures, and the thickness of the prepared tablets is 1.0 mm;

[0044] Use a square die cutter to cut the pressed...

Embodiment 2

[0048] Weigh 53 parts of wheat flour, 17 parts of corn starch, 18 parts of potato flour, 5 parts of poria powder, 4 parts of white granulated sugar, and 1.1 parts of edible salt, wherein the particle diameters of wheat flour, corn starch, potato flour and poria powder are all 27 mesh;

[0049] Wheat flour, potato flour and Poria cocos powder are fully mixed in a mixer to obtain mixed powder A;

[0050] Mix cornstarch, white sugar, and edible salt, and add warm water 1.5 times the total weight of cornstarch, white sugar, and edible salt and stir until completely dissolved to obtain a mixed liquid material B;

[0051]Add the mixed liquid material B into the mixed powder material A, add water until the water content of the mixture is 30%, and obtain the mixed material C;

[0052] The mixed material C is compressed by two tableting procedures, and the thickness of the prepared tablet is 1.1mm;

[0053] Use a square die cutter to cut the pressed sheet into regular square blank sli...

Embodiment 3

[0057] Weigh 55 parts of wheat flour, 20 parts of cornstarch, 20 parts of potato flour, 10 parts of Poria cocos powder, 7.5 parts of white granulated sugar, and 1.2 parts of edible salt, wherein the particle diameters of wheat flour, cornstarch, potato flour and Poria cocos powder are all 30 mesh;

[0058] Wheat flour, potato flour and Poria cocos powder are fully mixed in a mixer to obtain mixed powder A;

[0059] Mix cornstarch, white sugar, and edible salt, and add warm water twice the total weight of cornstarch, white sugar, and edible salt and stir until completely dissolved to obtain a mixed liquid material B;

[0060] Add the mixed liquid material B into the mixed powder material A, add water until the moisture content of the mixture is 35%, and obtain the mixed material C;

[0061] The mixed material C is compressed by two tableting procedures, and the thickness of the prepared tablet is 1.2mm;

[0062] Use a square die cutter to cut the pressed sheet into regular squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com