Agricultural crushing and inactivating device and use method thereof

An inactivation and agricultural technology, applied in grain processing, solid waste removal, etc., can solve problems such as mechanical agitation mechanism cannot be agitated, product characteristics are unstable, straw is rotten and mildewed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

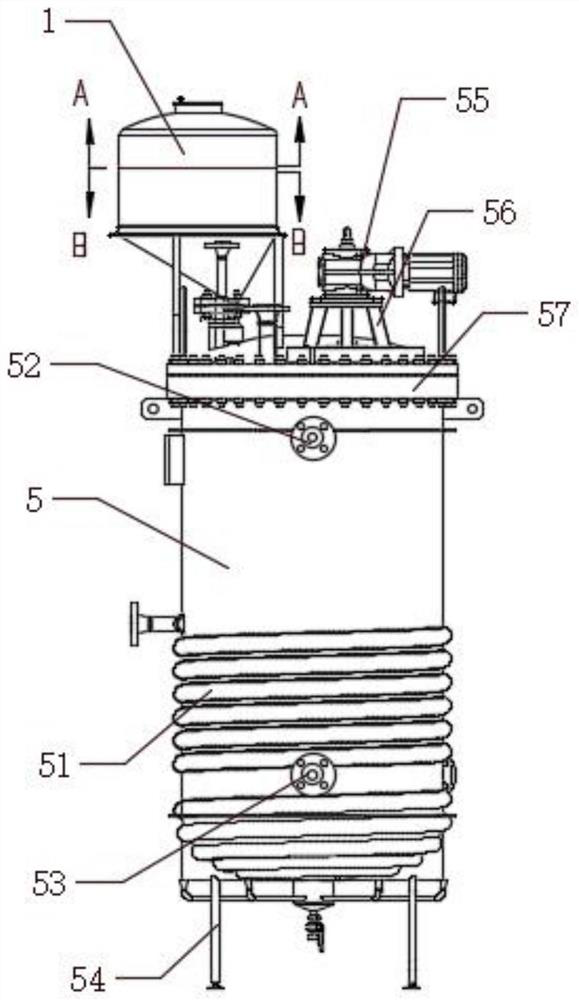

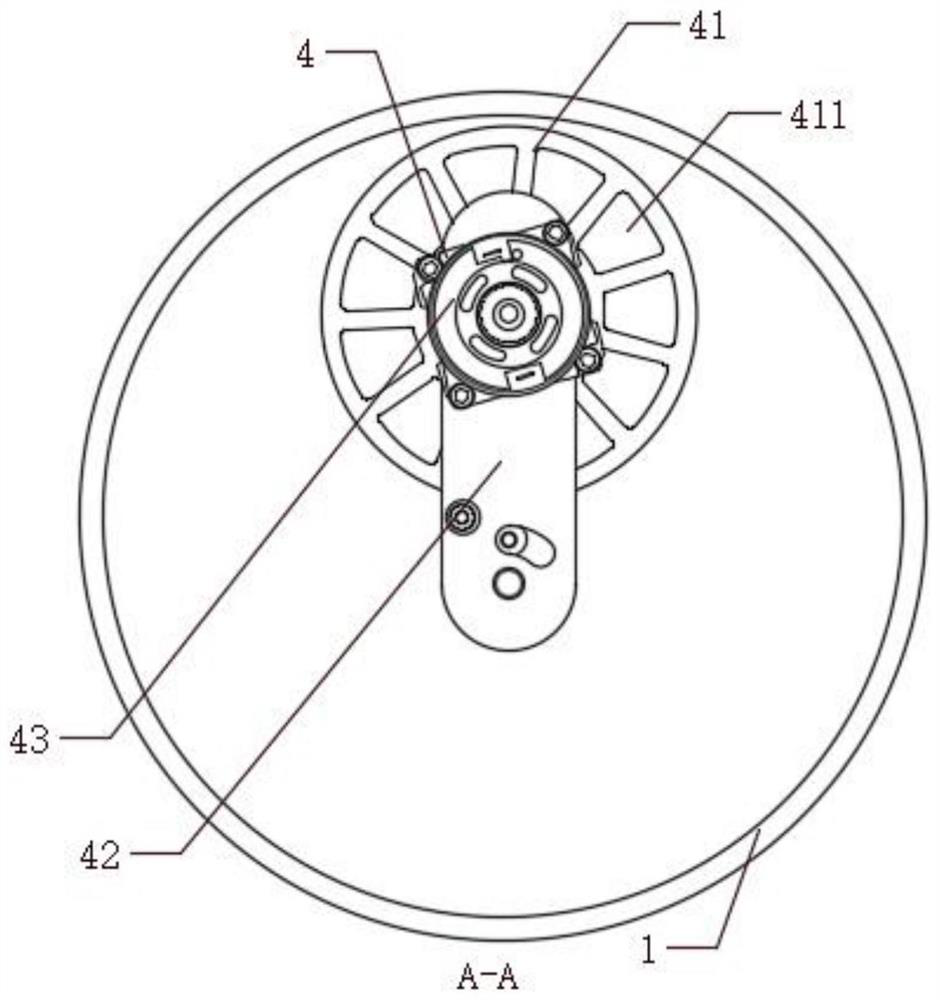

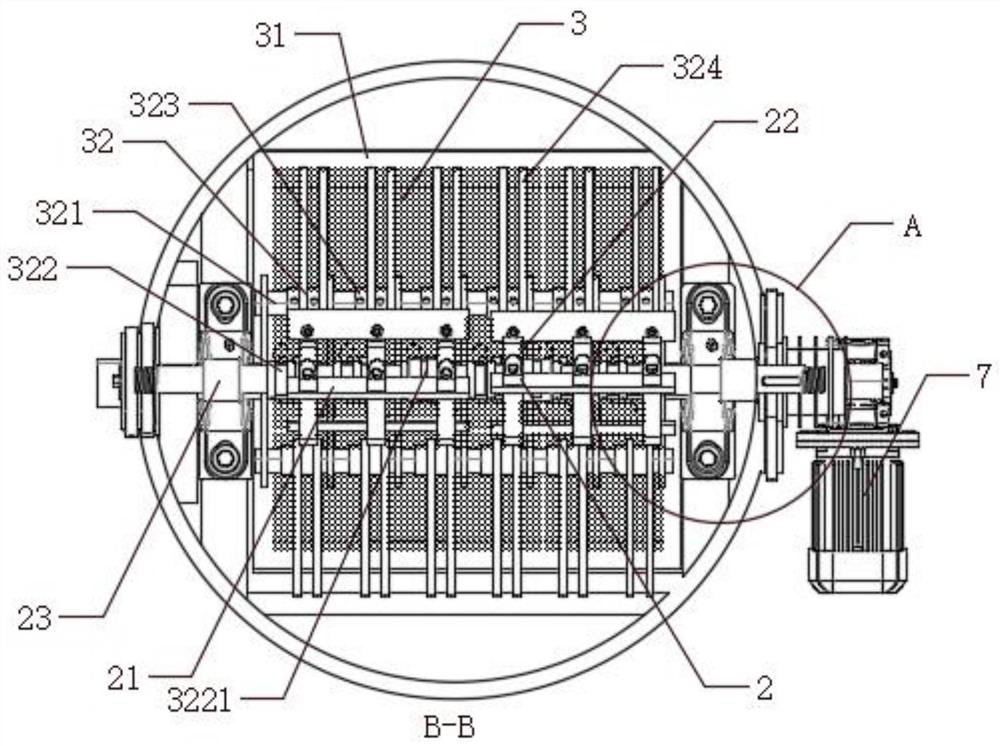

[0046] Such as Figure 1-6 As shown, an agricultural crushing and deactivation device of the present invention includes a tank body 1, a crushing assembly 2 arranged inside the tank body 1, a power assembly 7 arranged outside the tank body 1, and the power assembly 7 drives the crushing assembly 2 to rotate, The crushing assembly 2 includes a first cutter head body 21, a second cutter head body 22, and a bearing seat 23. The first cutter head body 21 and the second cutter head body 22 are detachably connected to the bearing seat 23, and the first cutter head body The crushing radii of the body 21 and the second cutter head body 22 are not equal.

[0047] Generally, when inactivating and fermenting straw materials, the existing devices are prone to unstable product characteristics after fermentation, and even some straws are rotten and mildewed. Observation and analysis have found that a large amount of straw materials without pretreatment are directly put into After entering ...

Embodiment 2

[0053] This embodiment is a further improvement of the previous embodiment, such as Figure 1-6 As shown, an agricultural crushing and deactivation device of the present invention includes a tank body 1, a crushing assembly 2 arranged inside the tank body 1, a power assembly 7 arranged outside the tank body 1, and the power assembly 7 drives the crushing assembly 2 to rotate, The crushing assembly 2 includes a first cutter head body 21, a second cutter head body 22, and a bearing seat 23. The first cutter head body 21 and the second cutter head body 22 are detachably connected to the bearing seat 23, and the first cutter head body The crushing radii of the body 21 and the second cutter head body 22 are not equal.

[0054] Generally, when inactivating and fermenting straw materials, the existing devices are prone to unstable product characteristics after fermentation, and even some straws are rotten and mildewed. Observation and analysis have found that a large amount of straw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com