Auxiliary device used for PCBA processing SMT stokehole visual inspection and using method

An auxiliary device and visual inspection technology, applied in auxiliary devices, metal processing, metal processing equipment, etc., can solve the problems of poor observation effect affecting engineers, affecting PCBA batches, and physical fatigue of engineers, so as to shorten production line waiting time, design The principle is reliable and the effect of improving the confirmation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

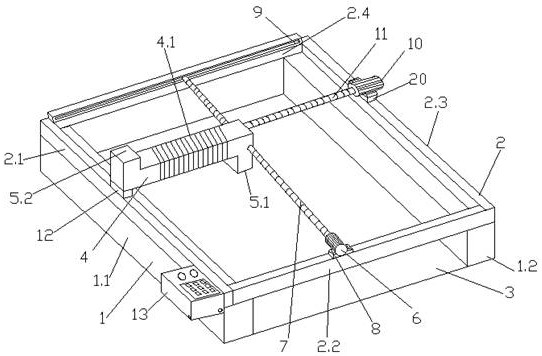

[0077] Such as figure 1 As shown, the present invention provides an auxiliary device for PCBA processing SMT furnace front visual inspection, including a positioning bracket 2, an auxiliary observation module, an observation drive module and a control module 13;

[0078] Parallel production line equipment guide rails 1 are arranged on both sides of the PCBA working surface 3 of the SMT furnace, the positioning bracket 2 is arranged on the upper part of the production line equipment guide rail 1, and the auxiliary observation module is arranged on the upper part of the positioning bracket 2;

[0079] The control module 13 is arranged on one side of the positioning bracket 2, and is connected with the observation drive module, and the observation drive module drives the auxiliary observation module to move horizontally and vertically along the positioning bracket 2, so as to realize the observation of each observation point of the PCBA working surface 3;

[0080] The auxiliary o...

Embodiment 2

[0085] Such as figure 1 As shown, the present invention provides an auxiliary device for PCBA processing SMT furnace front visual inspection, including a positioning bracket 2, an auxiliary observation module, an observation drive module and a control module 13;

[0086] The two sides of the PCBA working surface 3 of the SMT furnace are provided with parallel production line equipment guide rails 1, the positioning bracket 2 is set on the upper part of the production line equipment guide rail 1, and the auxiliary observation module is set on the upper part of the positioning bracket 2; the height of the SMT parts on the PCBA working surface 3 is the largest is 35mm, and the positioning bracket 2 is 40mm higher than the guide rail of the production line equipment;

[0087] The control module 13 is arranged on one side of the positioning bracket 2, and is connected with the observation drive module, and the observation drive module drives the auxiliary observation module to move...

Embodiment 3

[0121] Such as Figure 5 As shown, the present invention provides a method for using an auxiliary device for PCBA processing SMT furnace visual inspection, comprising the following steps:

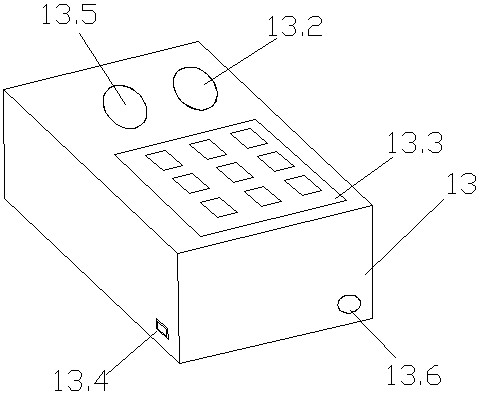

[0122] S1. Start the visual inspection auxiliary device through the start button, and reset the auxiliary observation module;

[0123] S2. The MCU control unit judges the work mode. When the work mode is automatic, the MCU control unit obtains the coordinate data of the observation point of the PCBA work surface through the USB interface, and when the work mode is manual mode, the MCU control unit obtains the PCBA work surface through the keyboard. watchpoint data;

[0124] S3. The MCU control unit controls the horizontal drive unit and the longitudinal drive unit to coordinate and drive the auxiliary observation module to move to the corresponding observation point on the PCBA working surface according to the acquired observation point data on the PCBA working surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com