Automatic plate processing equipment for customized furniture

A technology for automatic processing and sheet metal processing, applied in wood processing appliances, manufacturing tools, stationary drilling machines, etc., can solve the problems of high frequency, reduce the efficiency of production and processing of sheets, damage to raw materials, etc., to reduce intervention, reduce the risk of damage, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

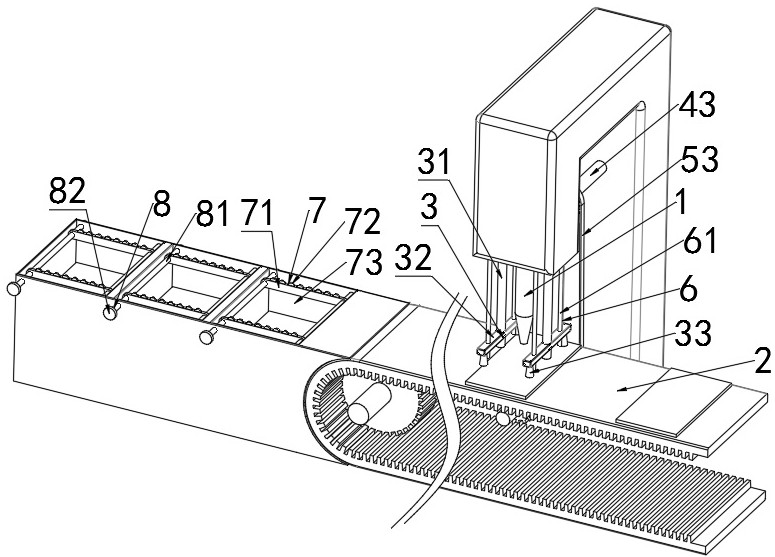

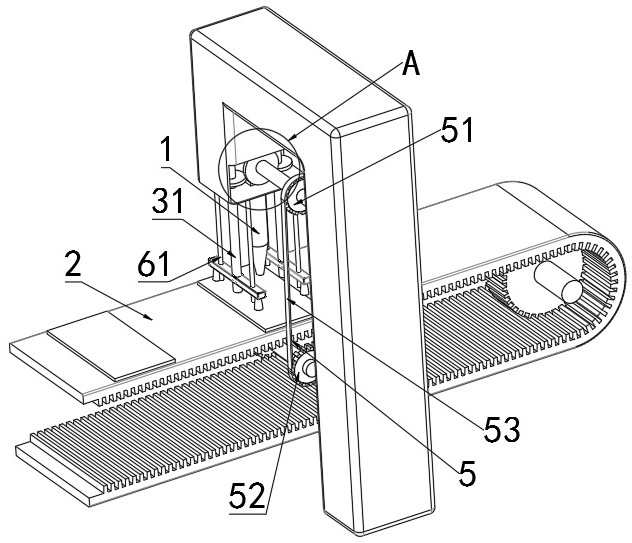

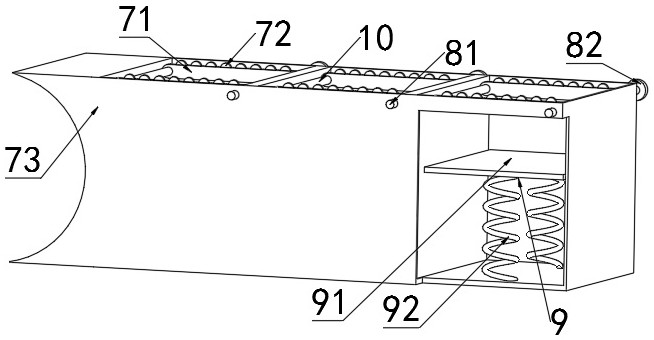

[0029] refer to Figure 1-5 , an automatic plate processing equipment for customized furniture, comprising;

[0030] Processing components, the processing components include a drill bit 1 and a frame, and are used for processing the plate, wherein the processing components and the drill bit 1 are all existing technologies, and will not be described again;

[0031] Conveyor belt 2, conveyor belt 2 includes a driving wheel and a plurality of driven wheels, the conveyor belt 2 is located under the drill bit 1, and is used for transporting plates, and the conveyor belt 2 is also a common driving wheel with driven wheels to drive the conveyor belt 2 moving mode, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com