Processing method and equipment for original ecological bamboo block

A technology of processing equipment and processing methods, which is applied in the field of wood-based panels and interior decoration materials, can solve the problems of inconsistent horizontal stretching and shrinkage of multiple pieces of recombined bamboo, failure to meet the production needs of enterprises, and low pass rate of bamboo squares, so as to reduce the amount of glue used , reduce cost input, and reduce the effect of bamboo fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

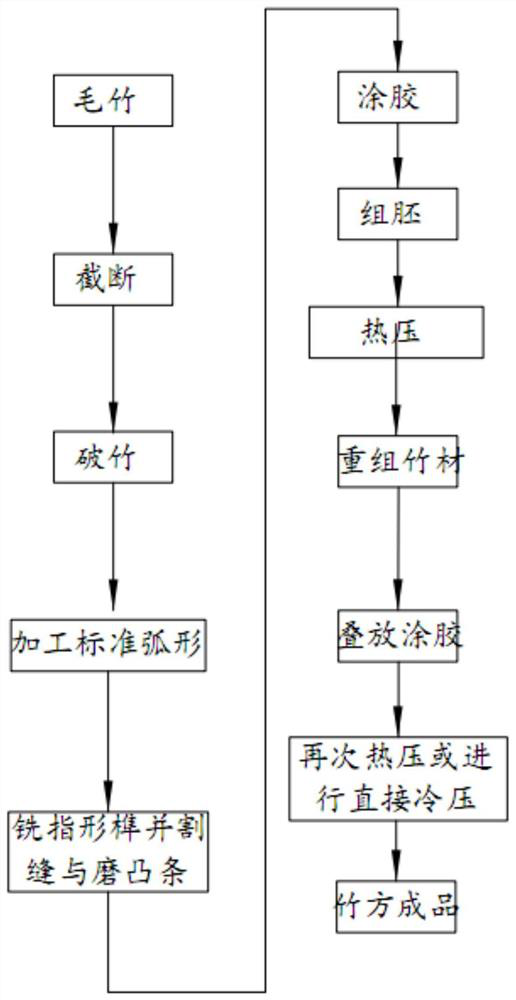

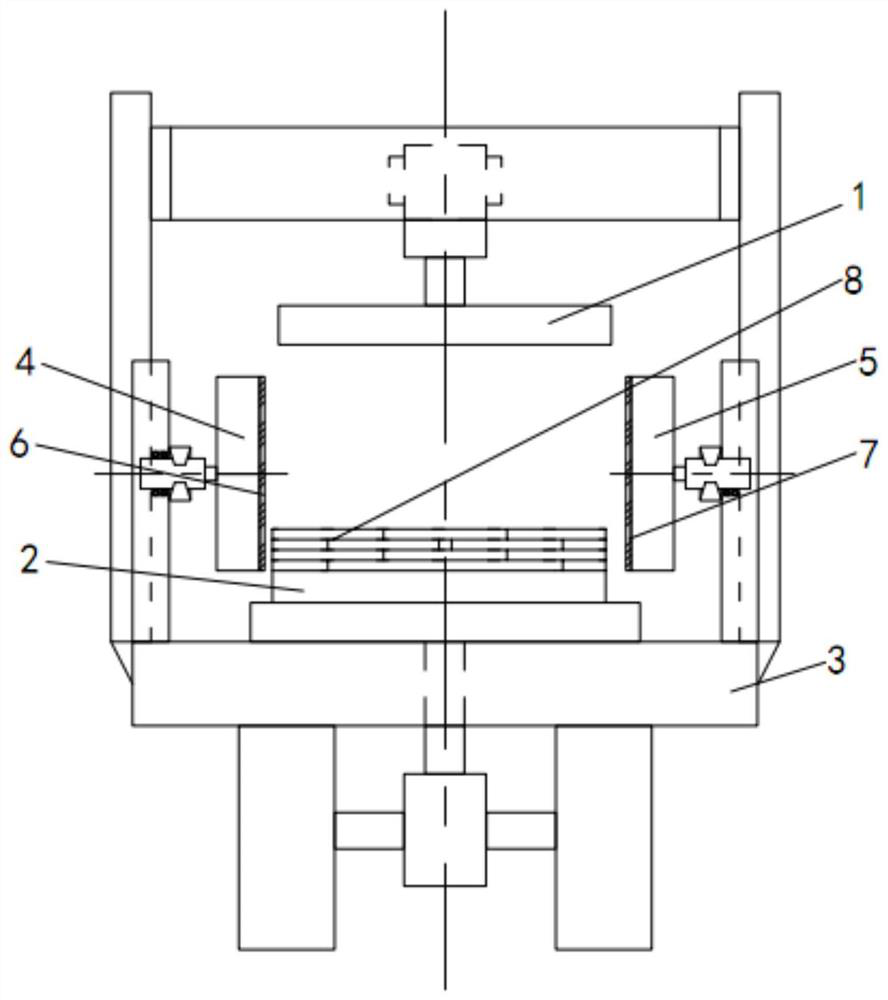

[0031] Such as figure 1 Shown, the processing method of a kind of original ecology bamboo side of the present invention comprises breaking bamboo, gluing, drying, hot press mold in-mold lamination arranging plate, hot pressing forming, specifically adopt following steps:

[0032](1) Moso bamboo is truncated according to the required specifications, and the bamboo section is obtained, and the raised bamboo joints on the outer surface of the bamboo section are cut off; the bamboo section is split into an arc-shaped bamboo piece blank; specifically: in step (1), the The moso bamboo is cut into bamboo sections with a length of 200mm, 250mm, 300mm, 450mm, 1000mm, 2000mm or 3000mm, and the bamboo sections are split into curved bamboos with a width of 10mm, 20mm, 50mm, 60mm, 70mm, 80mm, 100mm or 120mm piece blank.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com