Sensitivity enhancing device for hot-wire type acoustic mass point vibration velocity sensor

A technology of particle vibration velocity and enhancement device, applied in the field of sensors, can solve the problems of complex production, low sensitivity, complex structure, etc., and achieve the effects of increasing gain, increasing sensitivity, and clarifying directionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described now in conjunction with accompanying drawing.

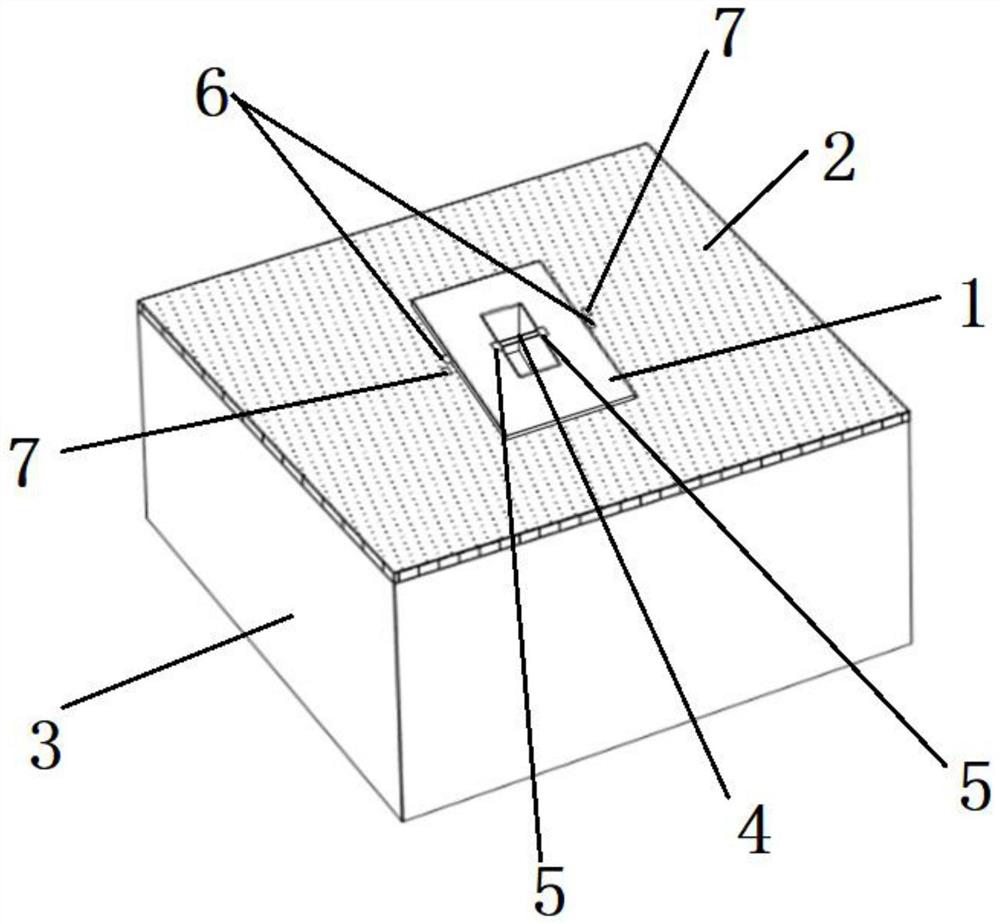

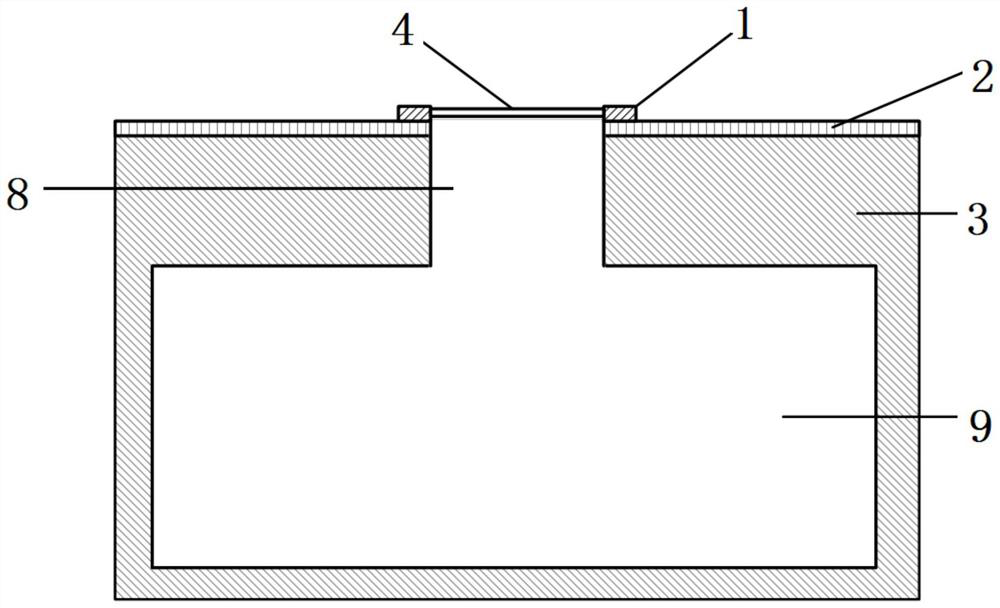

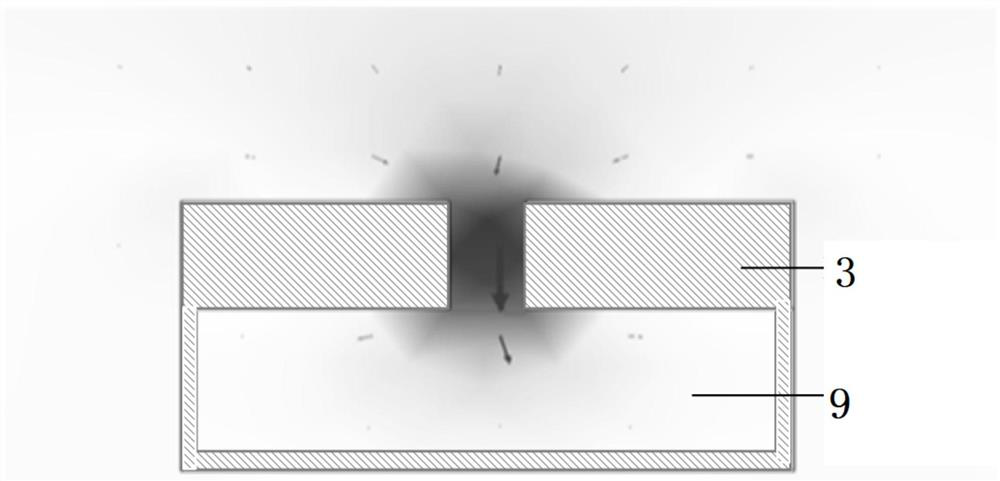

[0031] Such as figure 1 with 2 As shown, the present invention provides a sensitivity enhancement device for a hot-wire sound particle velocity sensor, which improves the sensitivity of the sound particle velocity sensor without affecting the perception of the direction of the sound particle velocity;

[0032] The device includes: MEMS chip 1, PCB board 2 (Printed circuit boards, printed circuit board) and acoustic resonance cavity 3;

[0033] A first rectangular hole is opened in the middle of the acoustic resonance cavity 3, and its interior is a hollow structure; a PCB board is arranged on the acoustic resonance cavity 3, and a second rectangular hole is opened in the middle of the PCB board; a MEMS chip is arranged on the PCB board , and the middle part of the MEMS chip is etched with a third rectangular hole, the middle part of the third rectangular hole is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com