Graphyne-based municipal solid waste incineration fly ash heavy metal curing material and preparation method thereof

A technology for municipal solid waste and incineration fly ash, which is used in the field of solidifying heavy metals in solidifying municipal solid waste incineration fly ash and its preparation field, can solve problems such as few studies, and achieve simple operation, significant innovative significance and application value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

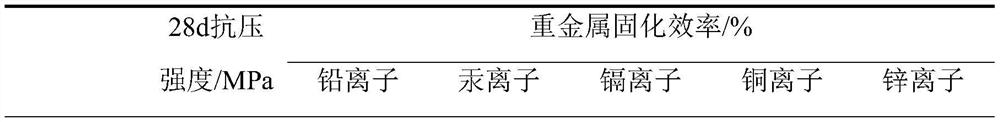

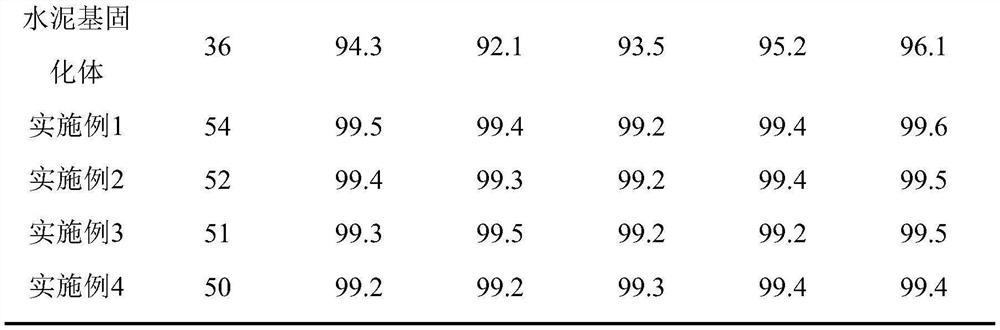

Examples

Embodiment 1

[0032] The raw materials of solidified fly ash of a municipal solid waste incineration plant are as follows:

[0033] Municipal solid waste incineration fly ash 200 parts, sodium metaaluminate 20 parts, water glass 180 parts, graphdiyne 5 parts, dispersant 25 parts, mixing water 325 parts.

[0034] The preparation steps are as follows:

[0035] Weigh dimethylformamide (DMF) as a dispersant, add mixing water into the beaker, and mechanically stir with a stirring rod. After the dispersant is completely dissolved, accurately weigh the graphyne nanomaterials in the dispersant solution and placed in an ultrasonic processor, ultrasonically treated for 30min at an ultrasonic power of 300W to obtain a uniformly dispersed graphyne dispersion, wherein the mass ratio of dimethylformamide to graphyne was 5:1.

[0036] Accurately weigh sodium metaaluminate and water glass to prepare an aluminosilicate activator, add sodium metaaluminate into water glass, and place on a magnetic stirrer to...

Embodiment 2

[0040] The raw materials of solidified fly ash of a municipal solid waste incineration plant are as follows:

[0041] Municipal solid waste incineration fly ash 275 parts, sodium metaaluminate 30 parts, water glass 250 parts, graphdiyne 3 parts, dispersant 15 parts, mixing water 380 parts.

[0042] The preparation steps are as follows:

[0043] Weigh dimethylformamide (DMF) as a dispersant, add mixing water into the beaker, and mechanically stir with a stirring rod. After the dispersant is completely dissolved, accurately weigh the graphyne nanomaterial in the dispersant solution and placed in an ultrasonic processor, ultrasonically treated for 25min at an ultrasonic power of 340W to obtain a uniformly dispersed graphyne dispersion, wherein the mass ratio of dimethylformamide to graphyne was 5:1.

[0044] Accurately weigh sodium metaaluminate and water glass to prepare an aluminosilicate activator, add sodium metaaluminate into water glass, and place on a magnetic stirrer to ...

Embodiment 3

[0048] The raw materials of solidified fly ash of a municipal solid waste incineration plant are as follows:

[0049] Municipal solid waste incineration fly ash 300 parts, sodium metaaluminate 40 parts, water glass 200 parts, graphdiyne 2 parts, dispersant 10 parts, mixing water 375 parts.

[0050] The preparation steps are as follows:

[0051] Weigh dimethylformamide (DMF) as a dispersant, add mixing water into the beaker, and mechanically stir with a stirring rod. After the dispersant is completely dissolved, accurately weigh the graphyne nanomaterials in the dispersant solution and placed in an ultrasonic processor, ultrasonically treated for 40min at an ultrasonic power of 180W to obtain a uniformly dispersed graphyne dispersion, wherein the mass ratio of dimethylformamide to graphyne was 5:1.

[0052] Accurately weigh sodium metaaluminate and water glass to prepare an aluminosilicate activator, add sodium metaaluminate into water glass, and place on a magnetic stirrer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com