Eddy current testing system for pipeline nondestructive testing

A non-destructive testing and eddy current testing technology, applied in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of low coupling between excitation coil and receiving coil, low sensitivity of detection probe and low lift-off height, etc. Energy transfer efficiency, improved detection capability, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

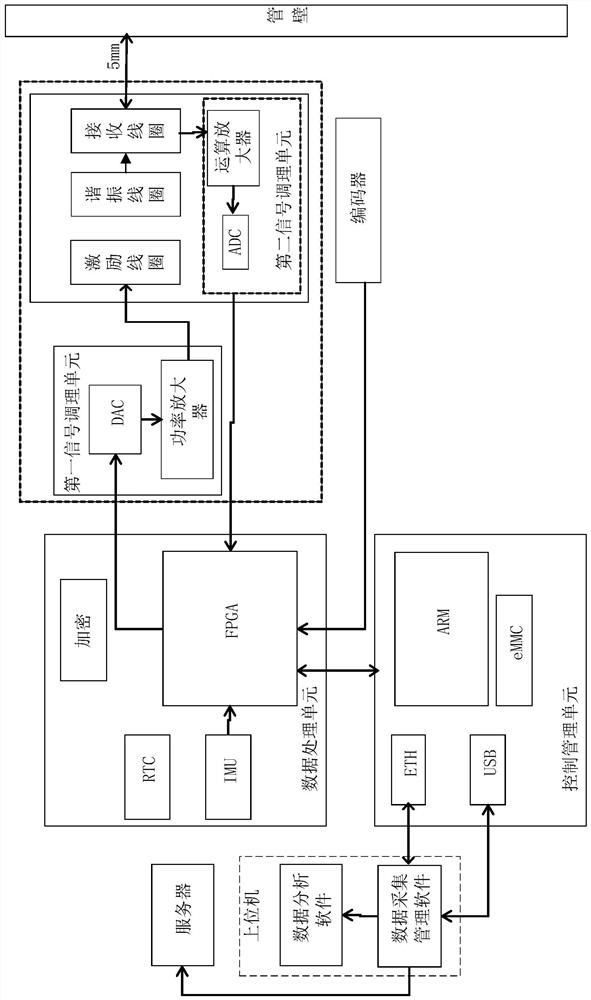

[0045] like figure 1 As shown, in Embodiment 1, the eddy current testing system for non-destructive testing of pipelines includes a data processing unit, a first signal conditioning unit, a second signal conditioning unit and a detection probe, and the detection probe includes a mutual inductance excitation coil and a receiving coil, It also includes a passive resonant coil arranged between the exciting coil and the receiving coil; the data processing unit, the first signal conditioning unit, and the exciting coil are connected in sequence, and the receiving coil, the second signal conditioning unit, and the data processing unit are connected in sequence. Among them, the data processing unit is used to generate the excitation signal to the first signal conditioning unit, and at the same time, it is used to receive the detection information fed back by the second signal conditioning unit, and is also used for MPU calibration, RTC time correction, etc. As an option, the data pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com