Soft package lithium cell assembly capable of prolonging service life of cell and lithium cell manufacturing method

A technology for lithium cells and components, applied in battery pack parts, electrolyte battery manufacturing, electrical components, etc., can solve problems such as incomplete trimming, reduced practicability, reduced service life, etc., to avoid angle changes, safety protection, The effect of reducing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

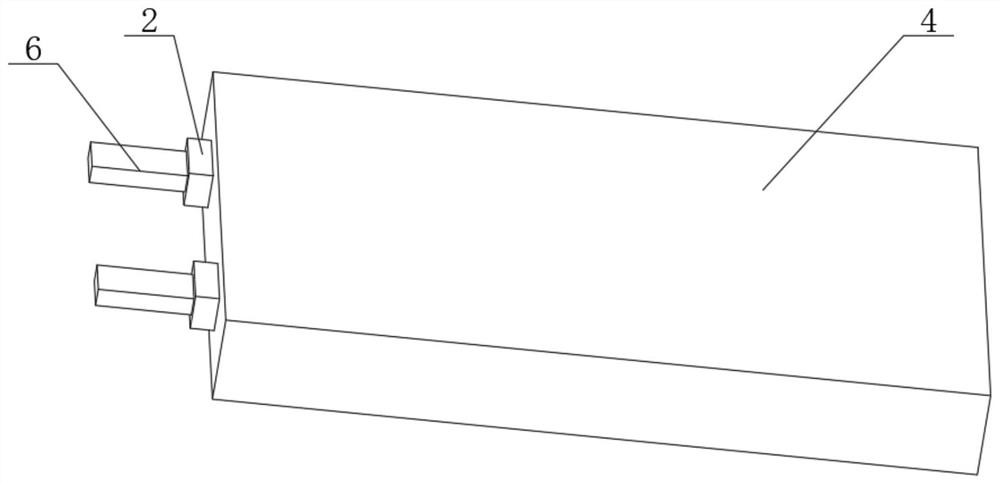

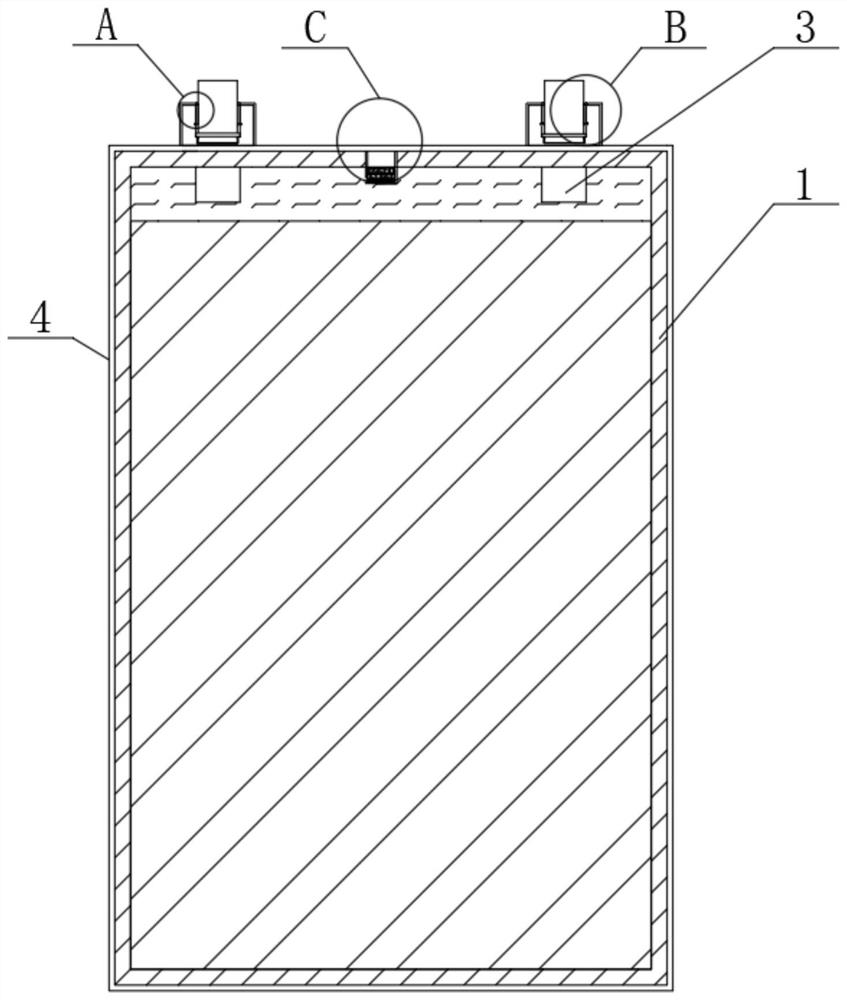

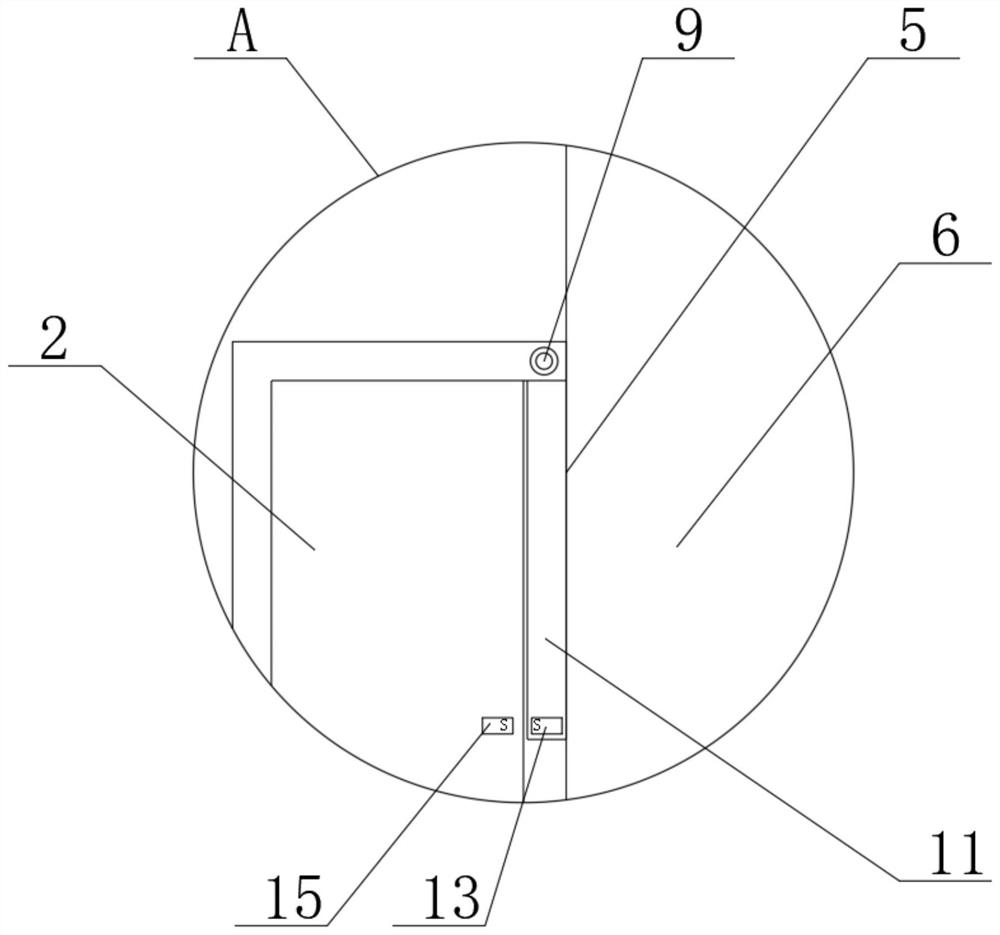

[0041] Please refer to Figure 1 to Figure 9 , a soft pack lithium cell assembly for prolonging the service life of the cell, comprising: a first aluminum-plastic packaging film 1, a first tab 3 is arranged inside the first aluminum-plastic packaging film 1, and the outer side of the first aluminum-plastic packaging film 1 A second aluminum-plastic packaging film 4 is provided, and an insulating sheet 2 is provided on the outer surface of the second aluminum-plastic packaging film 4 relative to the position of the first tab 3, and a replacement component is arranged inside the insulating sheet 2; the first aluminum-plastic packaging film 1 The upper surface of the upper surface is provided with an exhaust hole 17, and the exhaust hole 17 runs through the inside of the first aluminum-plastic packaging film 1, and the inside of the exhaust hole 17 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com