Method for preventing vibration in pumps

A technology of mechanical vibration and centrifugal pump, which is applied to the components of pumping device for elastic fluid, pump, pump control and other directions to achieve the effect of reducing mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention according to the present application describes a method for the targeted avoidance of unwanted vibration amplification in the case of resonance by means of a frequency converter during the operation of a pump, in particular a solids pump, a waste water pump or other supply pumps. The basis for the targeted avoidance of these resonances is that such resonance situations must first be detected by the pump controller, but as far as possible no special sensors, such as acceleration sensors, need to be added to the pump. However, nothing prevents the pump from being equipped with additional sensors, for example acceleration sensors, whereby the accuracy of the method can optionally be increased.

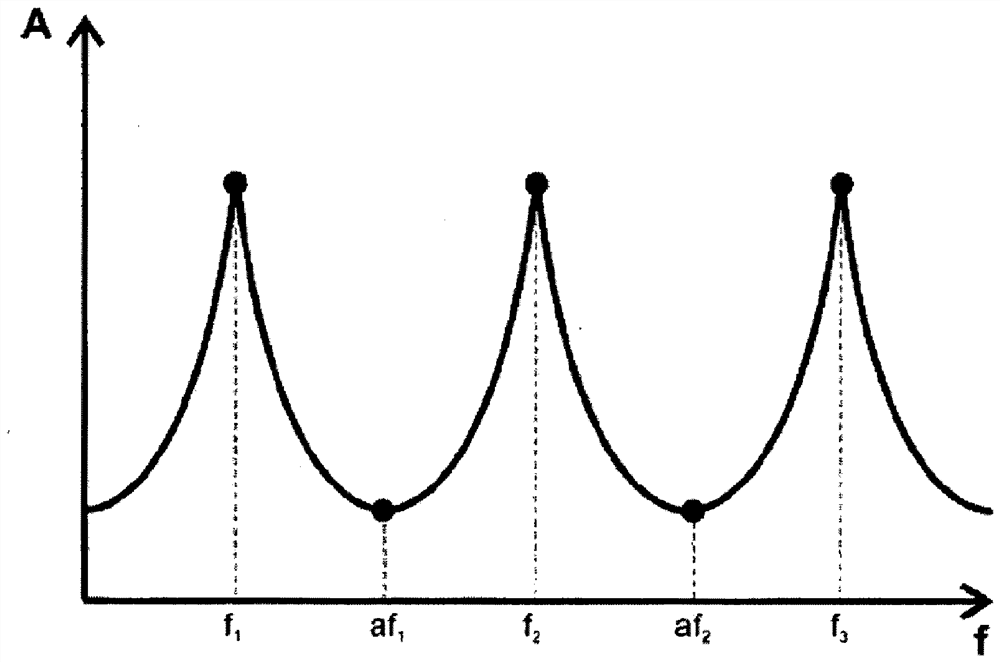

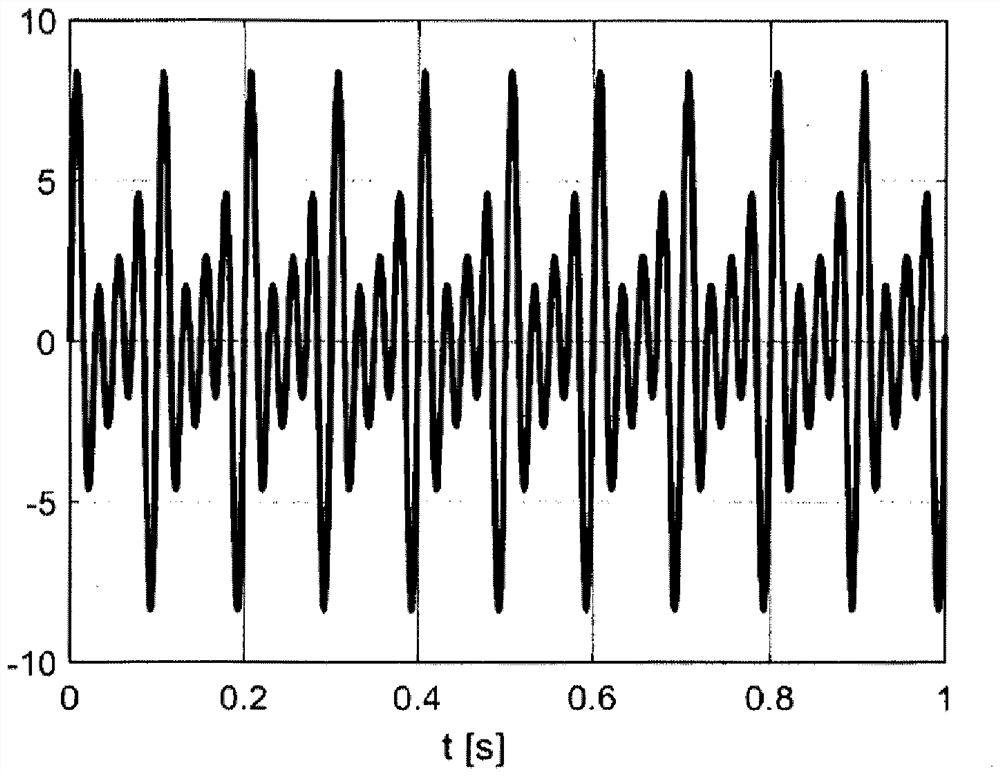

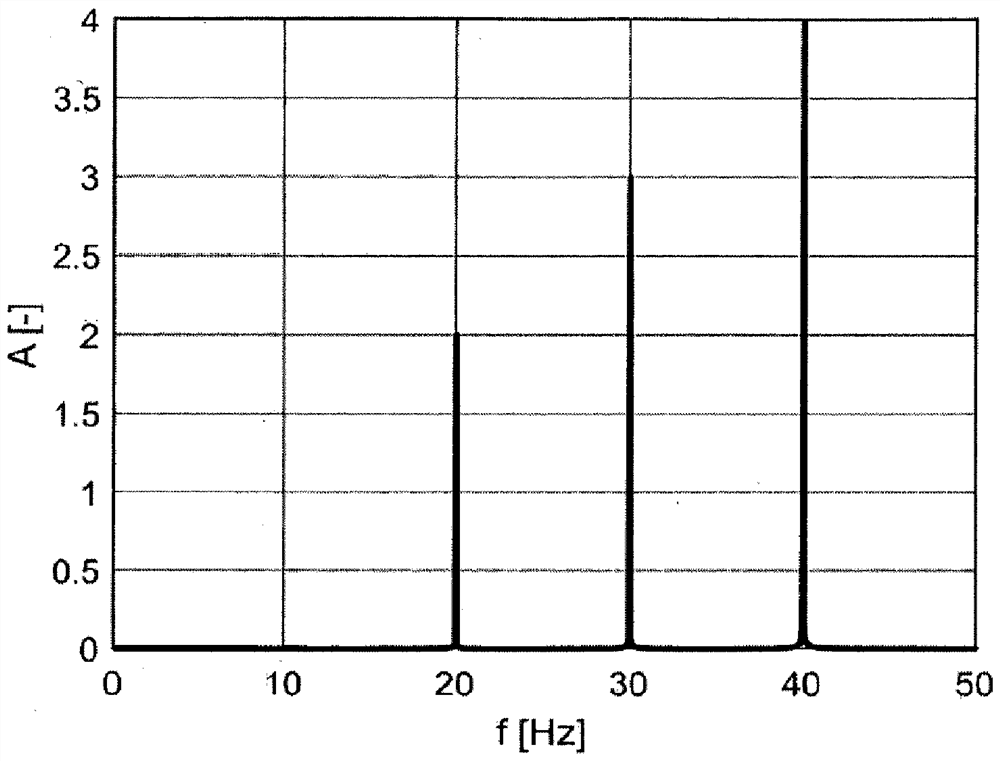

[0029] Since the mechanical vibrations are the result of the interaction of the constructional structure with the electric motor force, these mechanical vibrations can also be recognized as a superposition of the drive current of the pump current of the pump drive. Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com