Stain-resistant split-flow trap filter element for gas chromatograph and intelligent maintenance early warning system

A technology of gas chromatograph and early warning system, which is applied in the fields of pollution-resistant split trap filter element and intelligent maintenance early warning system for gas chromatograph, which can solve the problem of non-maintenance, gas chromatograph lack of life intelligent detection means of split trap system, and difficult Problems such as disassembly and observation can be achieved to reduce the pressure of manual maintenance, enrich the ability of intelligent judgment, and reduce the risk of downtime due to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

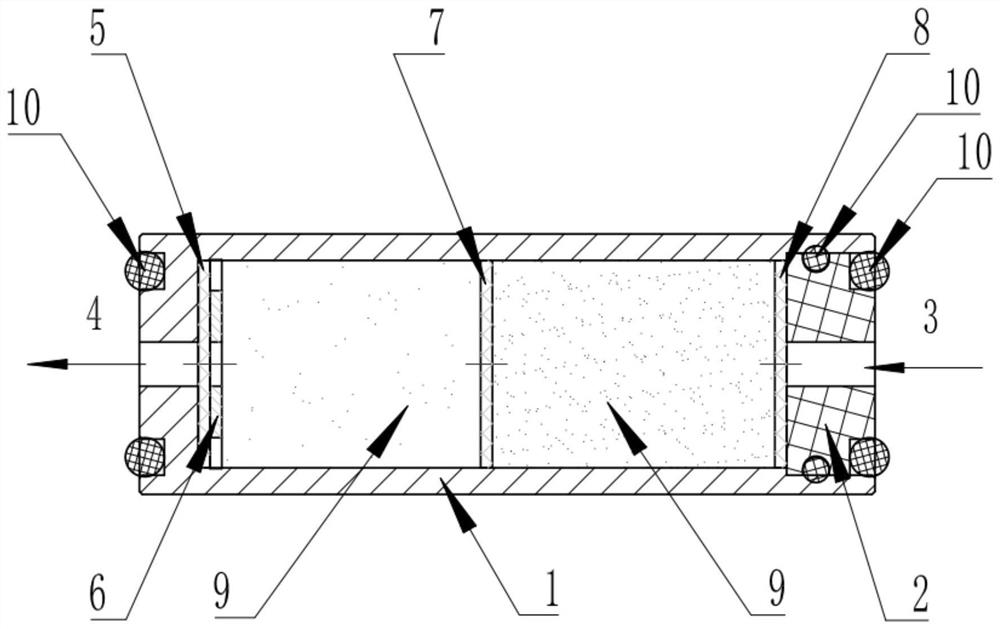

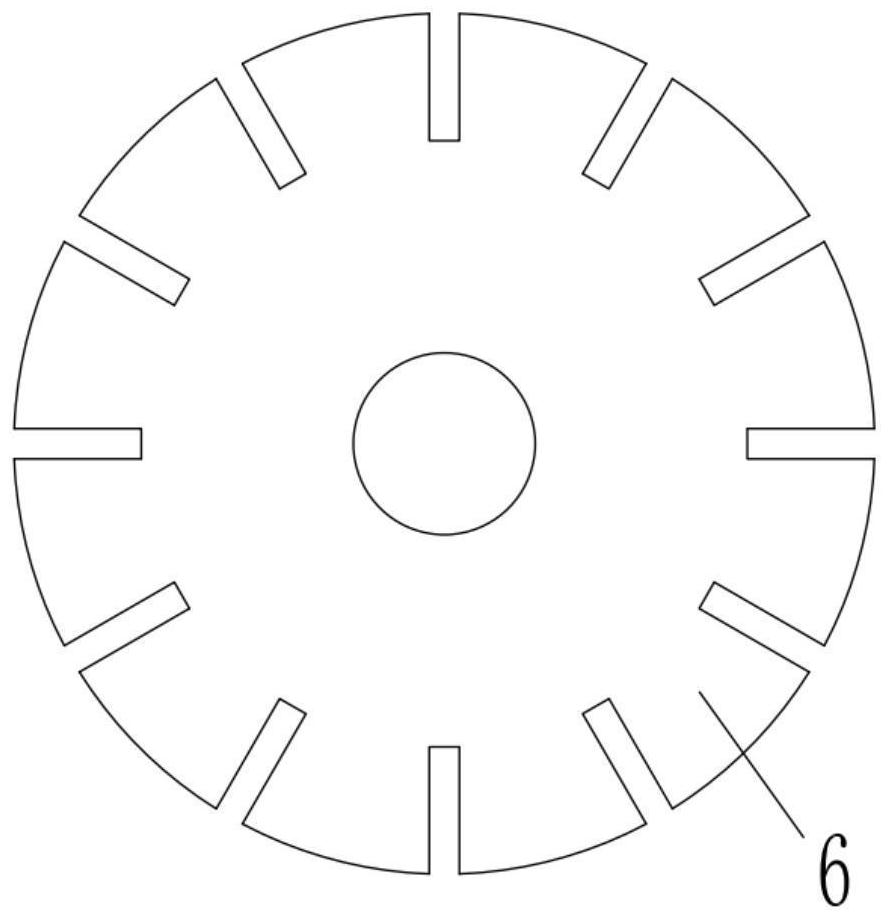

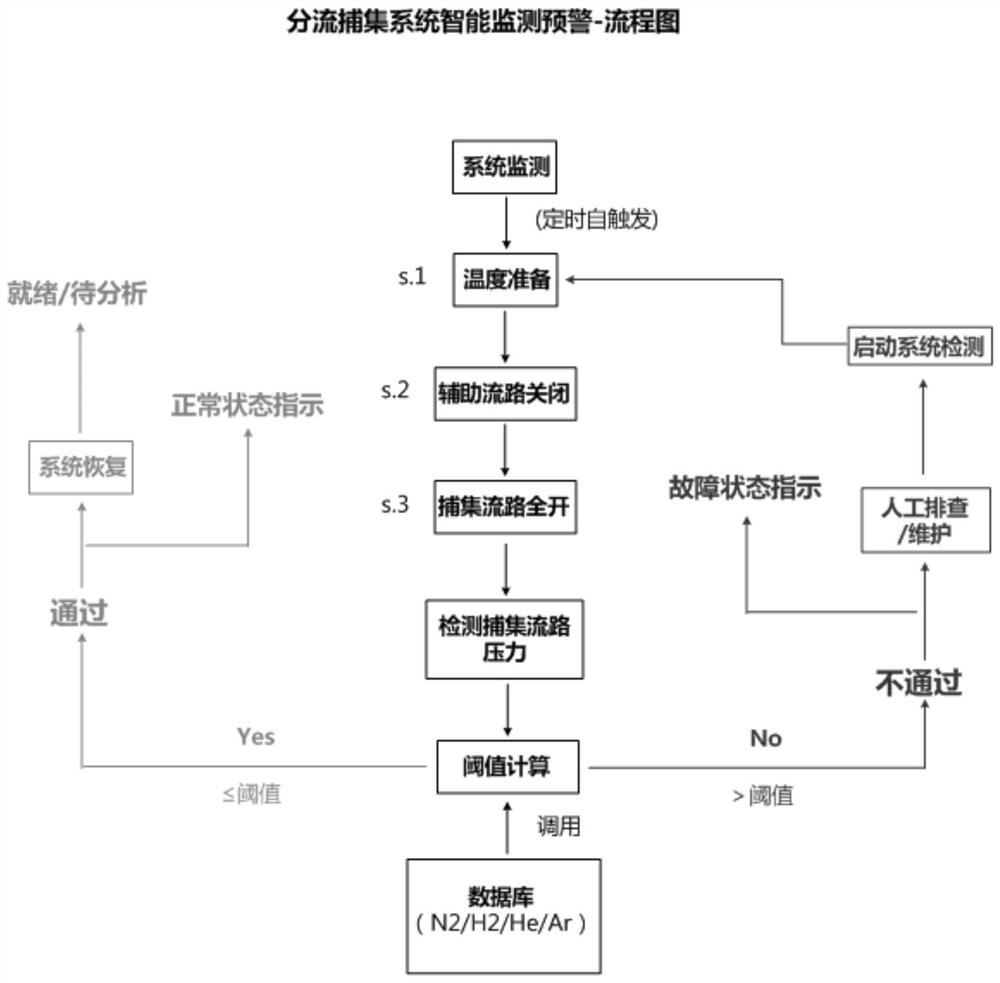

[0054] An intelligent maintenance early warning system, such as Figure 3-6 As shown, the system is based on the contamination-resistant split-trap cartridge for gas chromatographs described above. Its specific functions are realized in the following ways:

[0055] First of all, it needs to be pointed out that the following intelligent monitoring of pressure is accomplished through the above-mentioned pressure sensor, temperature sensor, control unit and display module that are in signal communication with each other.

[0056] The following intelligent management of maintenance and counting is accomplished through the counting module, the control unit and the display module which are set up in signal communication with each other.

[0057] (1) Intelligent monitoring system for pressure blockage:

[0058] Realization principle: With the continuous adsorption and capture of the target sample components by the adsorbent filled in the filter element in the diversion trap, the sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap