Efficient energy-saving wet dust collector based on cell biological mechanism

A wet dust collector, a high-efficiency and energy-saving technology, is applied in chemical instruments and methods, the use of liquid separation agents, and the separation of dispersed particles, which can solve the problems of serious environmental pollution and high operating costs of dust collectors, save investment and The effect of high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] A high-efficiency energy-saving wet dust collector based on cell biological mechanism, including:

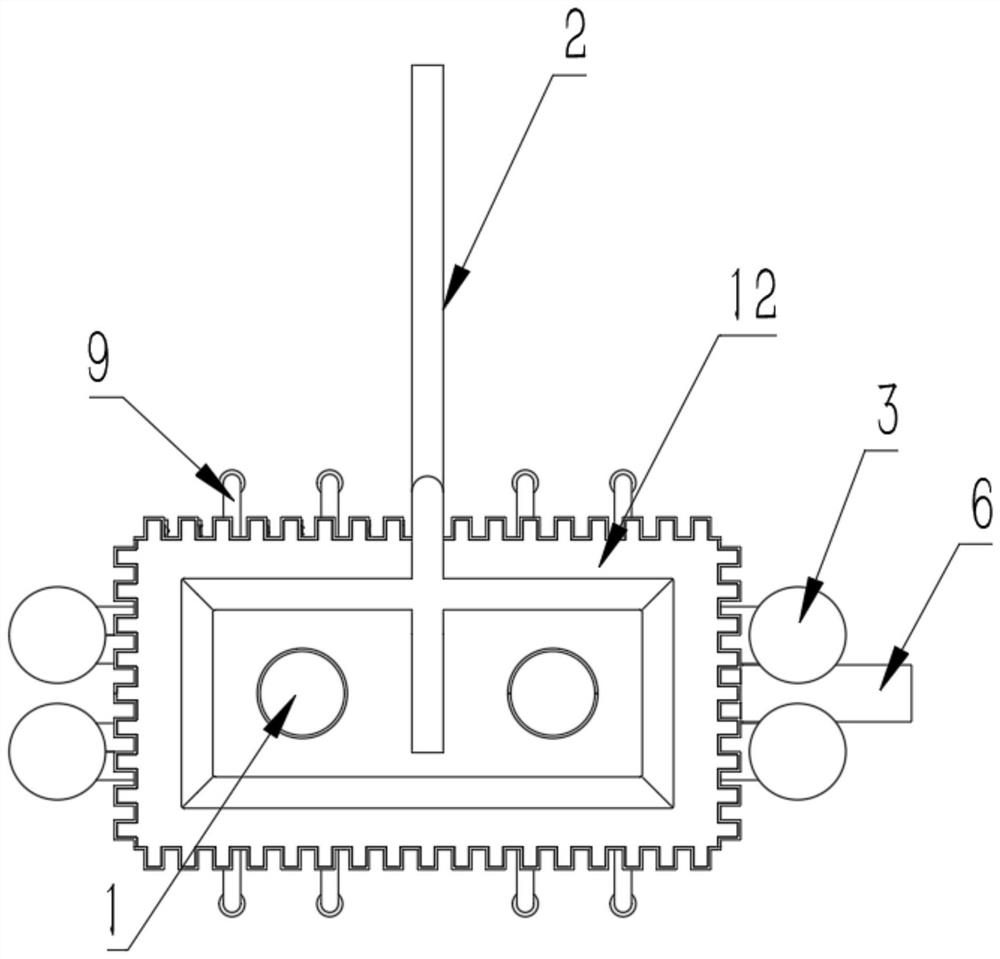

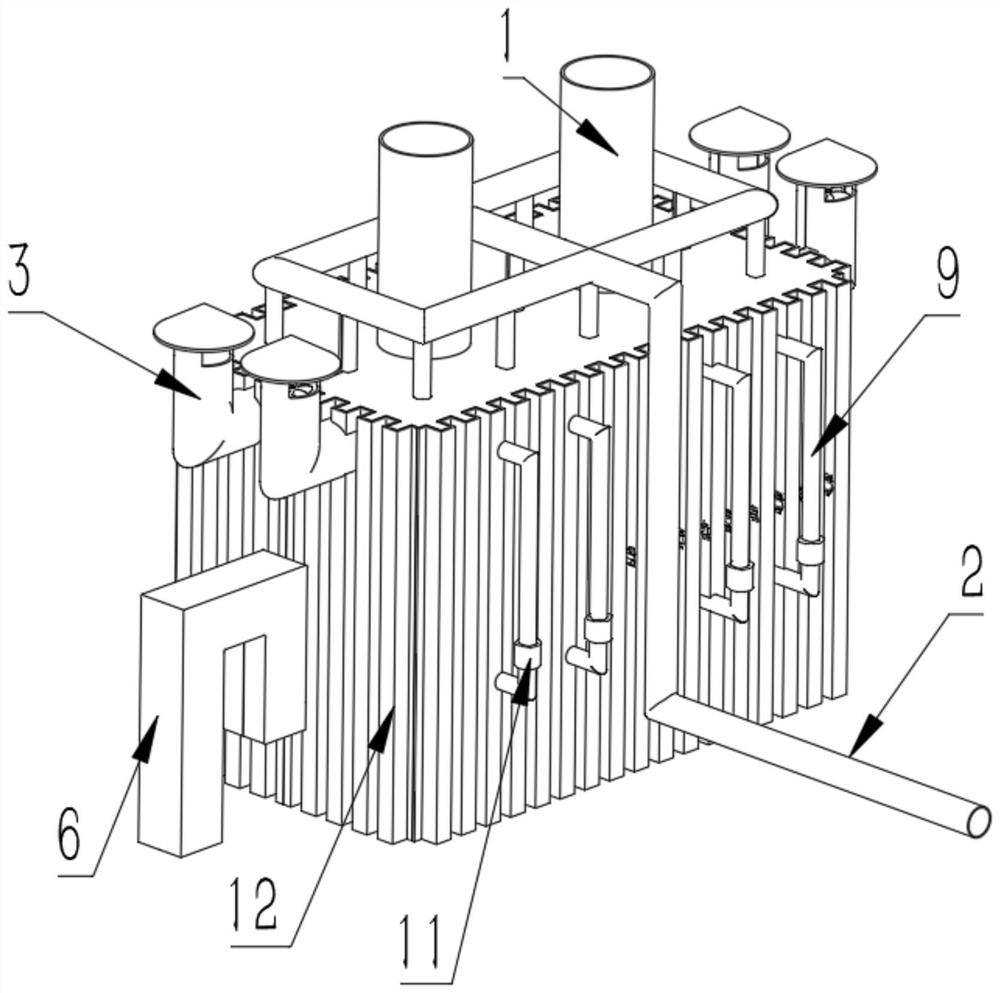

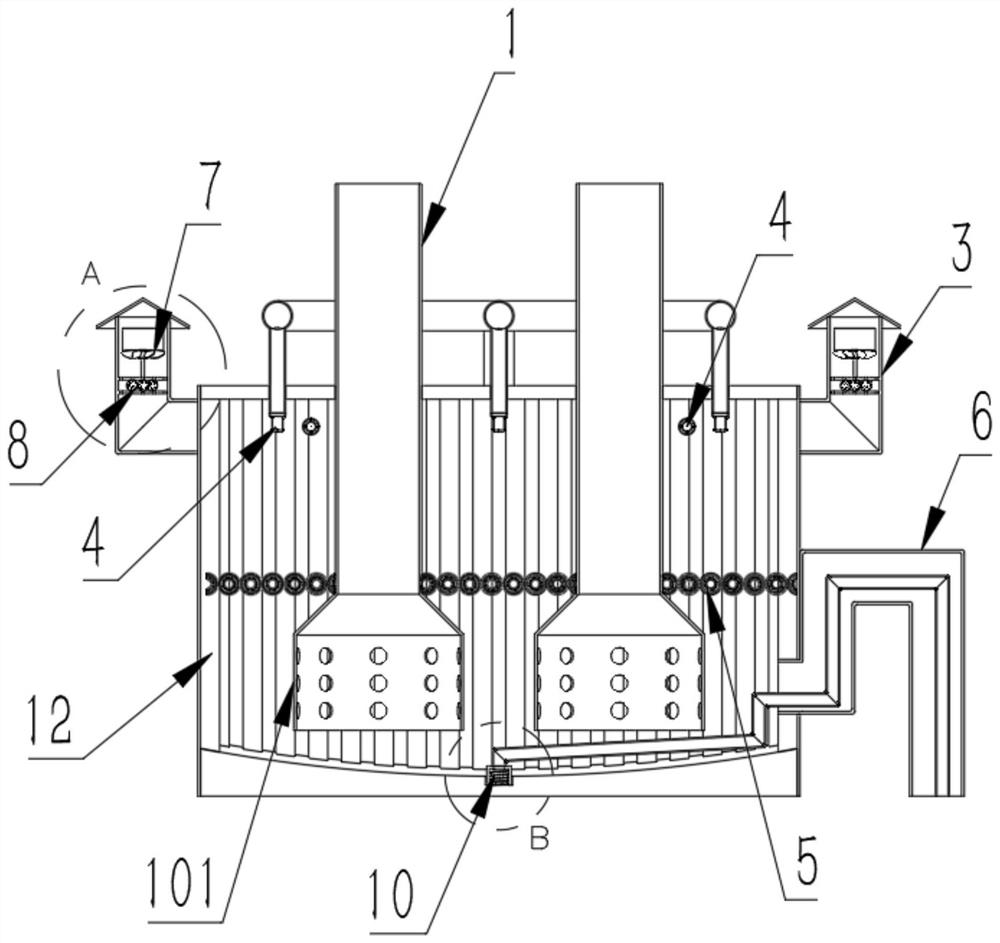

[0049] The housing 12 is in the shape of a box, and the side wall is composed of several-shaped bent steel plates. The side of the housing 12 is equipped with a connector 6, which is in the shape of a few characters and communicates with the housing 12; the bottom of the housing 12 An arc-shaped groove is provided, and a sand suction pump 10 is installed at the bottom of the arc-shaped groove, and the pipeline connected to the sand suction pump 10 passes through the connector 6 .

[0050] Dust inlet pipe 1, the upper part is cylindrical, connected to exhaust gas, the bottom is connected to the bell mouth 101, the bell mouth 101 is embedded in the water of the shell 12, and the bell mouth 101 is provided with multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com