Electronic refrigeration atmosphere pre-concentrator

An electronic refrigeration and concentrator technology, applied in the preparation of test samples, etc., can solve the problems that hinder the application of atmospheric pre-concentrators, high noise of liquid nitrogen, high cost, etc., to expand the scope of application, reduce volume and weight, and solve problems The effect of high running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

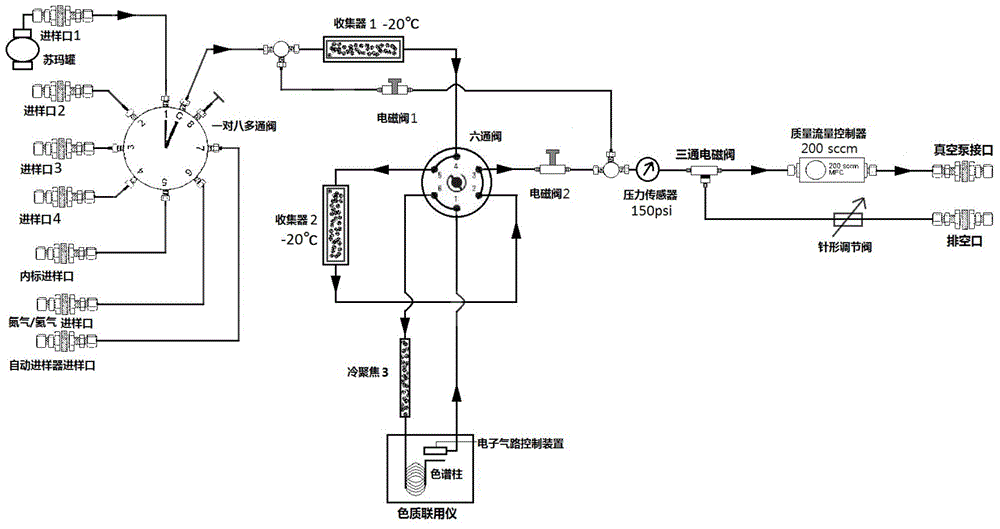

[0036] Such as Figures 1 to 4 As shown, the electronic refrigeration atmospheric pre-concentrator in this embodiment freezes the collector 1 and the collector 2 to -20°C at the same time. On the surface of the glass beads of the collector 1, the low-carbon compounds in the VOC enter the collector 2 and are adsorbed by the adsorbent, and at the same time, oxygen, nitrogen, carbon dioxide and inert gases are evacuated at one time; see the figure in the manual figure 1 .

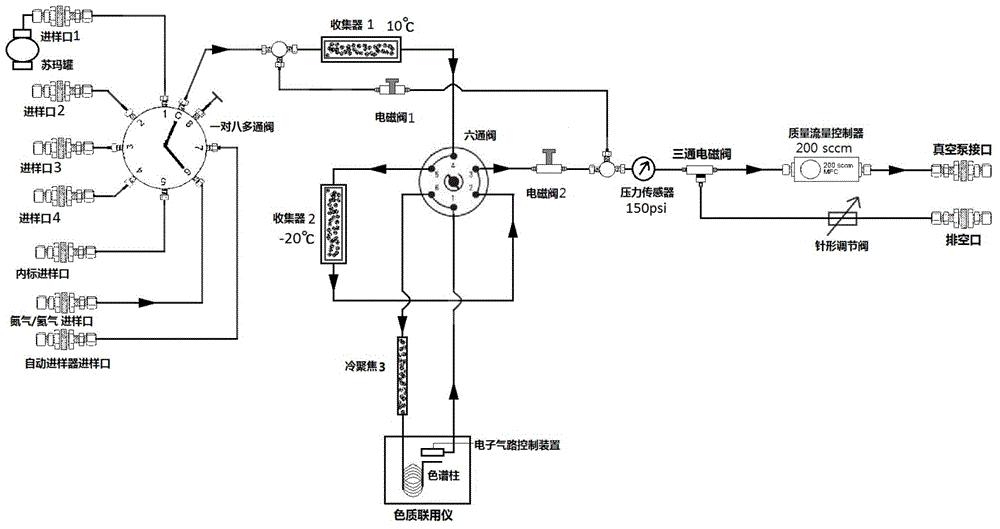

[0037] After the sample injection is completed, the temperature of collector 1 is increased from -20°C to 10°C, and the vaporized high-carbon compounds are transferred to collector 2 with nitrogen or helium at a flow rate of 15 ml per minute, and the water is retained. In the collector 1, the water, oxygen, nitrogen, carbon dioxide and inert gases in the sample are removed. See attached in the manual figure 2 .

[0038]The production of cold focus 3 can not use a stainless steel tube with a diameter of 0....

Embodiment 2

[0041] The electronic refrigeration atmospheric pre-concentrator of this embodiment differs from Embodiment 1 in that the temperature of the simultaneous freezing of the collector 1 and the collector 2 by the electronic refrigeration is different. Two collectors are used to collect VOC in sections at one time, and carbon dioxide, nitrogen, oxygen and inert gases are evacuated at one time. The water in the sample and the high-carbon compounds with high boiling point in VOC are collected by collector 1, while those with low boiling point are collected by collector 1. Low-carbon compounds are collected by the adsorbent in collector 2;

[0042] After the sample injection is completed, the collector 1 is heated to 0°C, and the high-carbon compounds in the collector 1 are transferred to the collector 2 with nitrogen or helium;

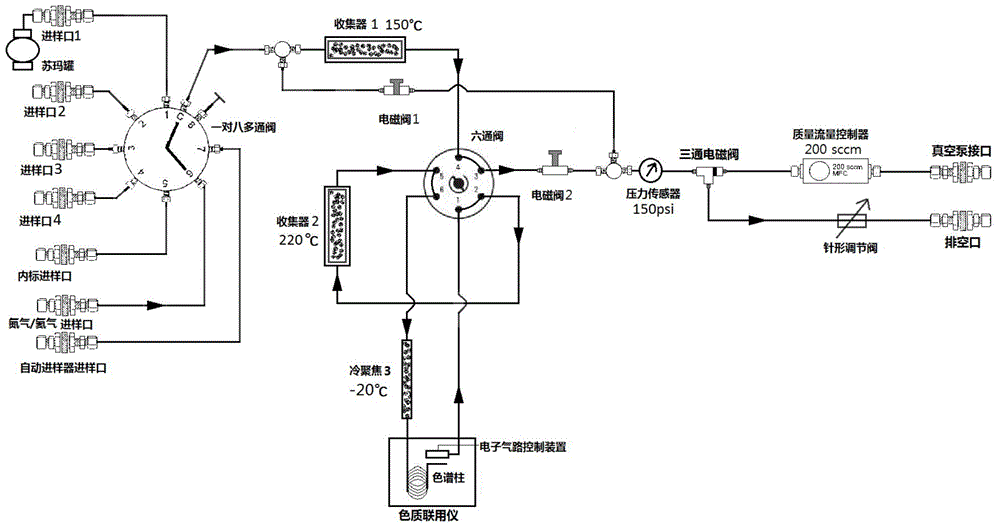

[0043] After the transfer, freeze the cold focus 3 to -60°C, then raise the temperature of the collector 2 to 220°C, use helium to transfer the VOC to the c...

Embodiment 3

[0045] The structure of the electronic refrigeration atmospheric pre-concentrator in this embodiment is the same as that of Example 1, the difference is that the electronic refrigeration freezes the collector 1 and the collector 2 to -30°C at the same time, injects samples in series, and uses two collectors at a time. The collector collects VOC in sections, and at the same time evacuates carbon dioxide, nitrogen, oxygen and inert gases at one time. The water in the sample and the high-carbon compounds with high boiling points in VOC are collected by collector 1, while the low-carbon compounds with low boiling points are collected by collector 1. Sorbent collection in vessel 2;

[0046] After the sample injection is completed, the collector 1 is heated to 30°C, and the high-carbon compounds in the collector 1 are transferred to the collector 2 with nitrogen or helium;

[0047] After the transfer, freeze the cold focus 3 to -60°C, then raise the temperature of the collector 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com