Multi-row multi-shaft furniture wood drilling machine

A furniture woodworking and drilling machine technology, applied in the field of multi-row and multi-axis furniture woodworking drilling machines, can solve problems such as damage to the surface of the board, reduced performance, no safety protection, etc., and achieves improved performance, reduced friction, and is not easy to scratch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

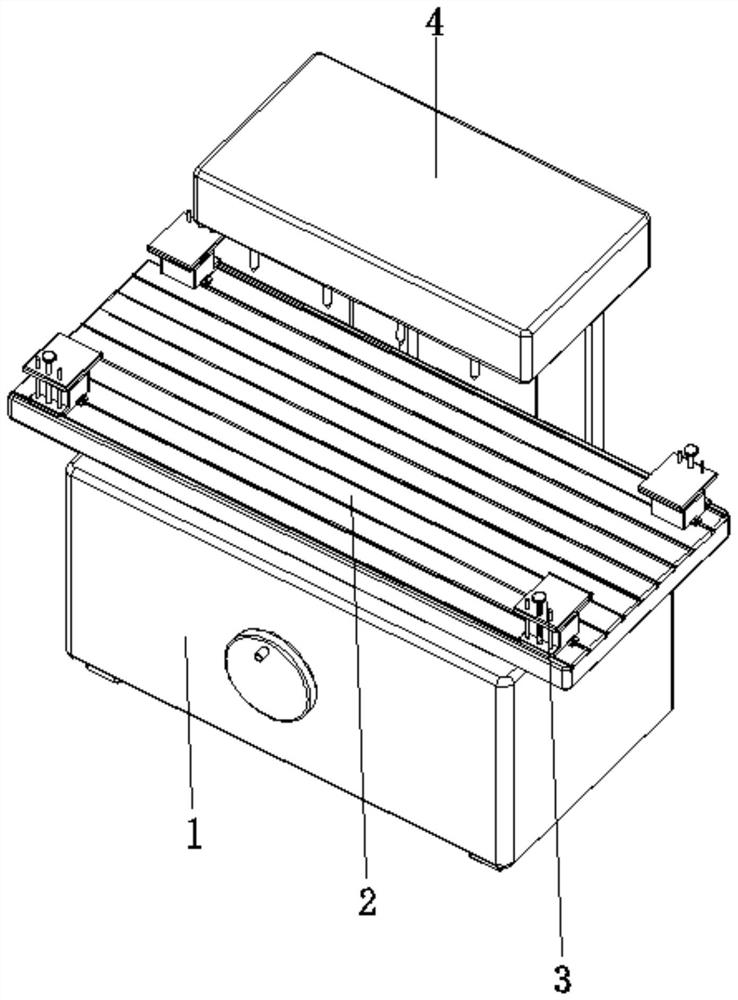

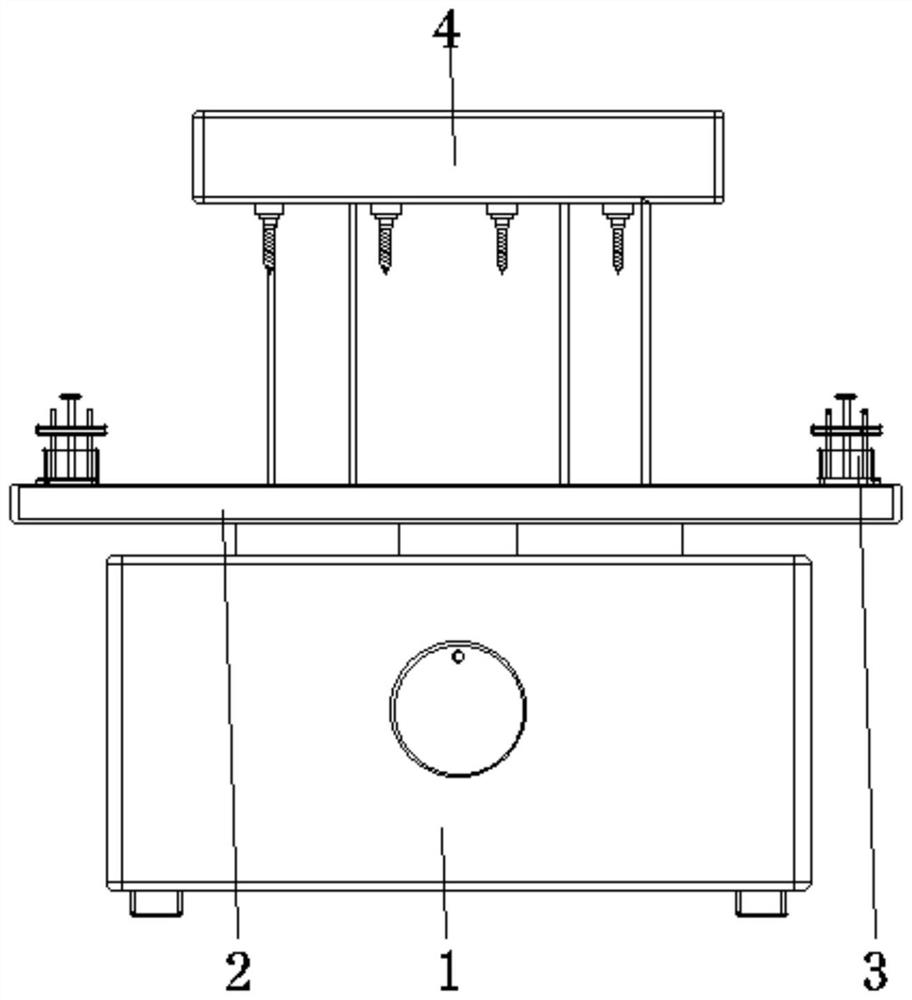

[0031] see Figure 1-7 , the present invention provides a technical solution: a multi-row multi-axis furniture woodworking drilling machine, including a body 1, a workbench 2, a clamping device 3, a multi-row multi-axis drilling mechanism 4, and the workbench 2 is arranged on the top of the body 1 , the clamping device 3 is arranged at a position corresponding to the top of the workbench 2, and the multi-row multi-axis drilling mechanism 4 is arranged on the top side of the surface of the body 1 and is located at the top of the workbench 2;

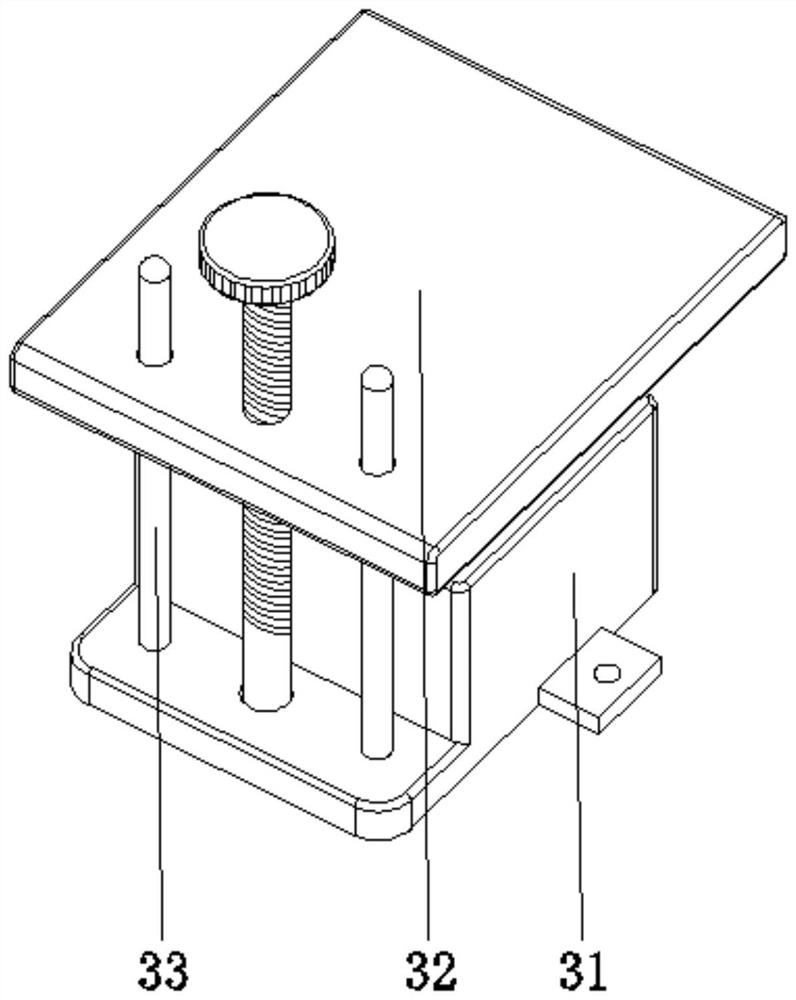

[0032] The clamping device 3 is provided with a supporting device 31, a pressing device 32, and a guide rod 33. The bottom of the supporting device 31 is fixedly connected with the top of the workbench 2, and the pressing device 32 is connected with the supporting device 31. The bottom end is fixedly connected to the bottom side of the surface of the support device 31, and the surface of the guide rod 33 is connected with the pressing dev...

Embodiment example 2

[0034]The support device 31 is provided with a base 311, a bracket slide plate 312, a support spring 313, a rolling device 314, and an air outlet device 315. The bottom of the base 311 is fixedly connected to the top of the workbench 2, and the support slide plate 312 is slidably connected to the base 311 inside and close to the top position, the support spring 313 is fixed between the top of the inner wall of the bracket slide plate 312 and the corresponding two sides inside the base 311, the rolling device 314 is arranged inside the base 311 and is located at the top position, the rolling device 314 The end part is connected with the bracket slide plate 312, and the air outlet device 315 is arranged inside the base 311 and directly below the rolling device 314. When the plate needs to be clamped, the plate is placed on the supporting device 31, and the plate is The rolling device 314 is pressed down by its own weight, and supported by the base 311, and the plate is clamped by...

Embodiment example 3

[0036] Compression device 32 is provided with threaded rod 321, pressing plate 322, anti-skid pad 323, and the bottom of threaded rod 321 is connected with the surface bottom edge of support device 31 in rotation, between pressing plate 322 and the surface of threaded rod 321, threaded connection, anti-slip pad 323 Fixed on the bottom of the pressure plate 322, the threaded rod 321 can be turned in time to drive the pressure plate 322 to move up and down, thereby realizing the loosening and clamping of the plate, and the guide rod 33 is used to make the whole structure more stable. And the downward pressure of the pressing plate 322 is applied to the supporting device 31, further making the plate placed smoothly without moving or shaking, and the combination of structures is used to improve the support and clamping of the plate, which is helpful for fast drilling.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap