Fluidized bed coal gasifying gas-cavity-free distribution plate and fluidized bed coal gasifying assembly

A coal gasification and fluidized bed technology, applied in gasification process, gasification device feeding tool, granular/powder fuel gasification, etc. Cost, uniform gas distribution, use reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

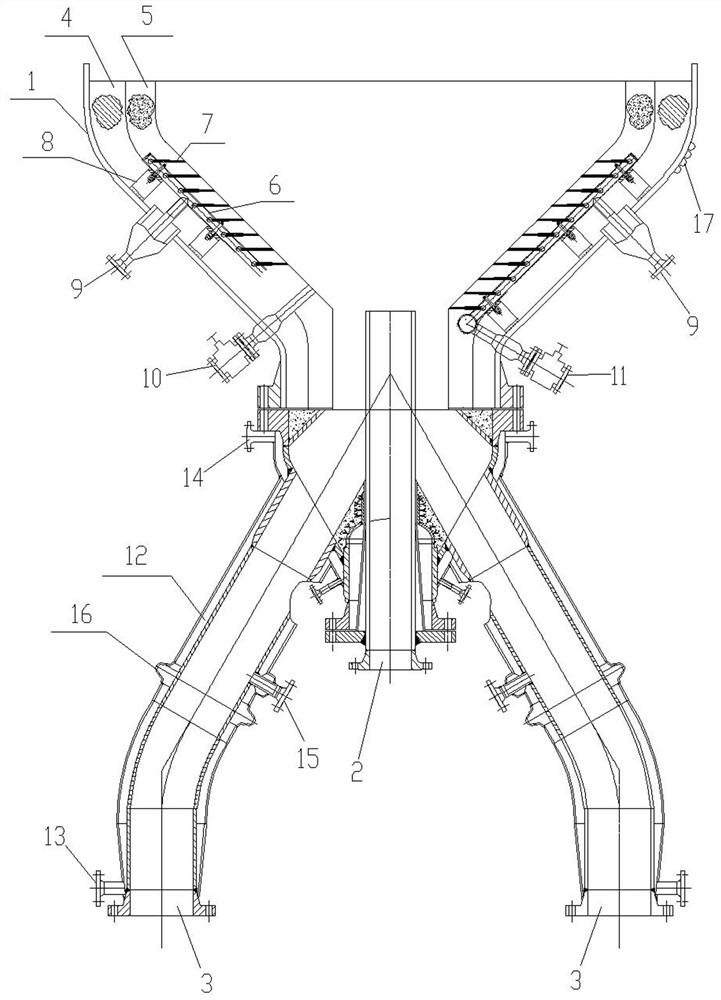

[0027] A distribution plate for fluidized bed coal gasification without an air chamber. The distribution plate for fluidized bed coal gasification without an air chamber is a metal plate that can withstand the internal pressure of the gasifier from the outside to the inside. 1. A preset amount of gasification agent Distribution main pipe fixing part 8, gasification agent distribution main pipe 6 and a preset number of gasification agent distribution branch pipes 7; among them, gasification agent distribution main pipe fixing part 8, gasification agent distribution main pipe 6 and gasification agent distribution branch pipe 7 Both are buried in the refractory insulation layer 4 and the refractory and wear-resistant layer 5 laid on the inside of the metal plate 1, and the outlet of the gasification agent distribution branch pipe 7 is flush with the inner surface of the refractory and wear-resistant layer 5; The gasification agent inlet 9 connected to the distribution main pipe; t...

Embodiment 2

[0030] A fluidized bed coal gasification assembly, including the distribution plate of the fluidized bed coal gasification airless chamber in embodiment 1, and also includes a central jet tube and a slagging structure, and the powder return port 10 is located in the fluidized bed coal gasification airless chamber At the position below the gas chamber distribution plate near the top of the central jet pipe 2, the bottom of the fluidized bed coal gasification airless distribution plate and the slag discharge structure are connected by flanges, which facilitates the installation and connection between the airless chamber distribution plate and the slag discharge structure. Disassembly; the center jet structure is a vertical center jet tube 2, the height of the top of the center jet tube is equal to the height of the cone bottom of the airless distribution plate above it, the top of the center jet tube is a free end, and the lower part and the slag discharge structure pass through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com