Engine hydraulic suspension system and method for achieving suspension vibration resistance through engine hydraulic suspension system

A hydraulic mount and engine technology, applied in the direction of power devices, shock absorbers, mechanical equipment, etc., can solve the problems of insufficient matching degree of anti-vibration effect, poor adjustability of vibration reduction effect, etc., to achieve convenient operation and ensure anti-vibration ability , good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

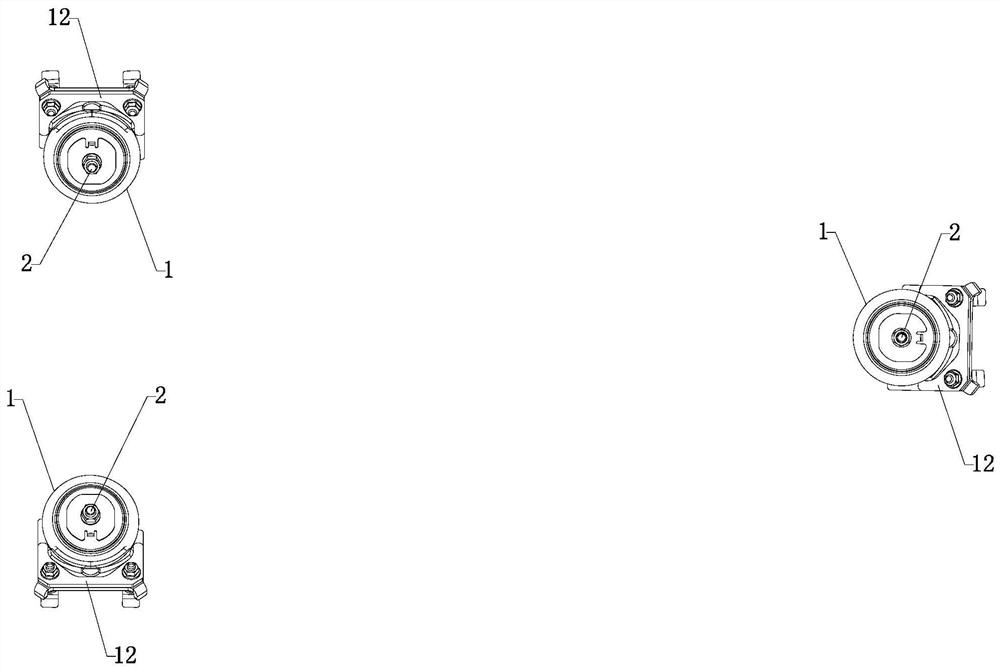

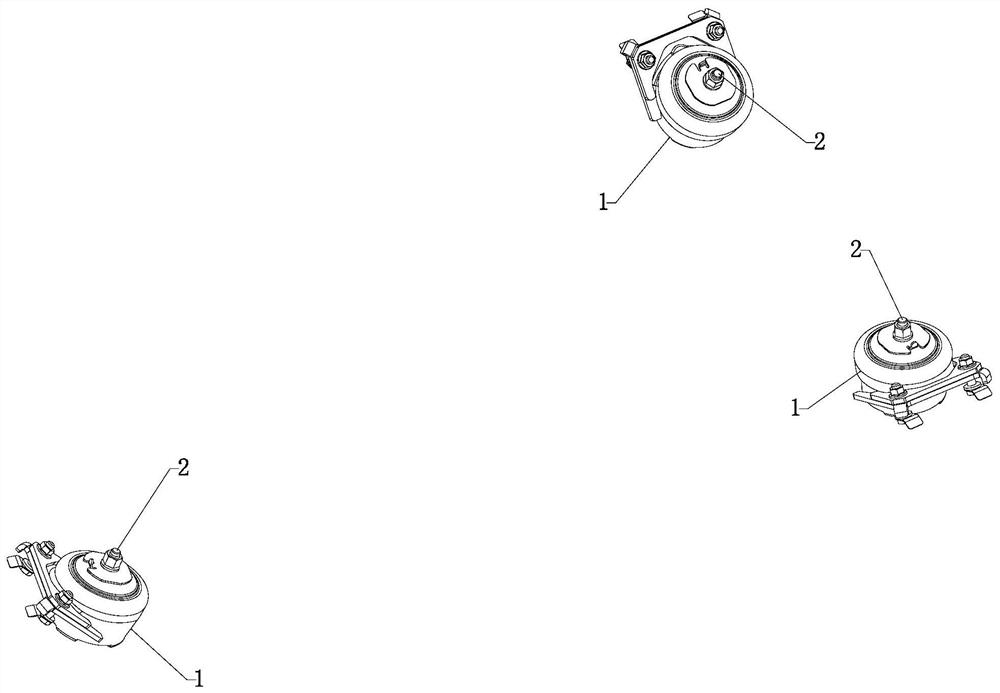

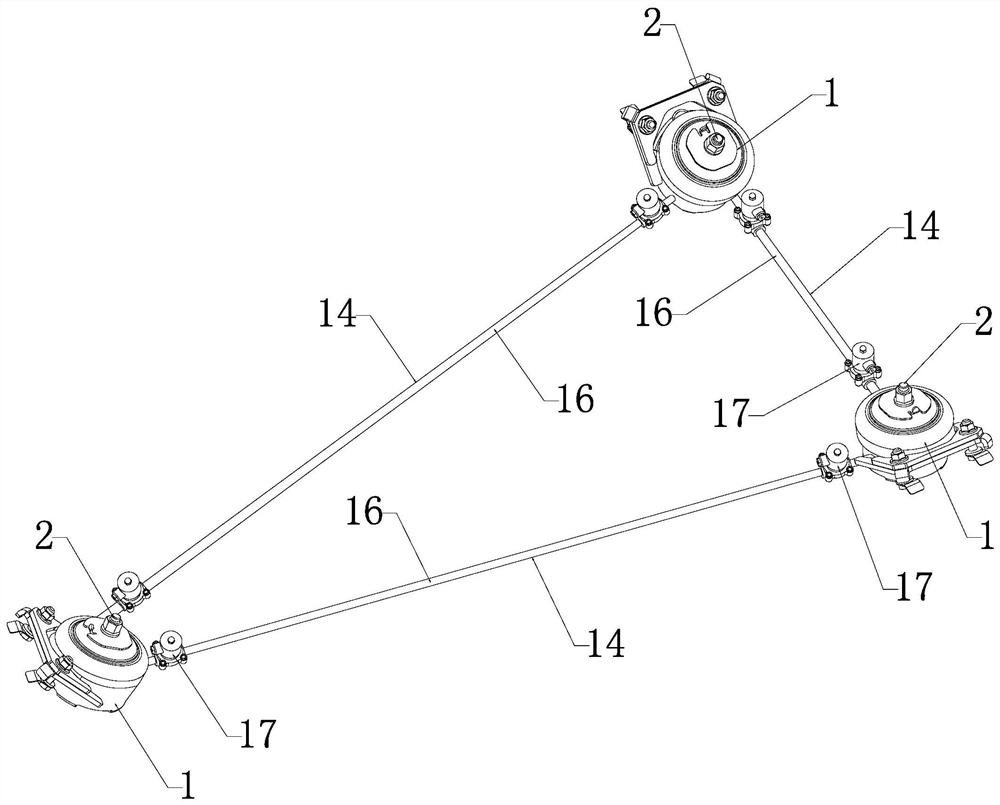

[0062] Embodiment 1: The engine hydraulic mount system includes three hydraulic mounts 1, and the three hydraulic mounts 1 are fixedly bolted to the vehicle frame at the top and the engine assembly at the bottom through connecting pieces respectively; Two hydraulic mounts 1 are installed symmetrically on both sides of the front end above the engine assembly, and a third hydraulic mount 1 is installed in the middle of the rear end above the engine assembly. The three hydraulic mounts 1 are in the form of The three-point support distribution in the shape of an isosceles triangle realizes the support for the engine assembly.

[0063] The three suspension mechanisms all adopt the hydraulic suspension mechanism 1, which can ensure the unity of the three-point support, and can effectively form a triangular coordination suspension support, so as to achieve the purpose of stable support.

[0064] In any of the above schemes, it is preferable that the hydraulic suspension mechanism 1 i...

Embodiment 2

[0067] Embodiment 2: Embodiment 1: engine hydraulic mount system, including three hydraulic mounts 1, wherein, two said hydraulic mounts 1 are symmetrically installed on both sides of the front end above the engine assembly, A third hydraulic mount 1 is installed in the middle section of the upper rear end, and the three hydraulic mounts 1 are distributed at three points in the shape of an isosceles triangle to support the engine assembly. The three hydraulic mounts 1 The vehicle frame on its top and the engine assembly on its bottom are respectively fixed and bolted by connecting piece 12 .

[0068] The three suspension mechanisms all adopt the hydraulic suspension mechanism 1, which can ensure the unity of the three-point support, and can effectively form a triangular coordination suspension support, so as to achieve the purpose of stable support.

[0069] In any of the above schemes, it is preferable that the hydraulic suspension mechanism 1 includes an upper connecting bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com