Elastic plugging valve for pipeline

A pipeline and valve blocking technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of large engineering volume, sewage infiltration, high cost, low construction cost, reduced workload and quality Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

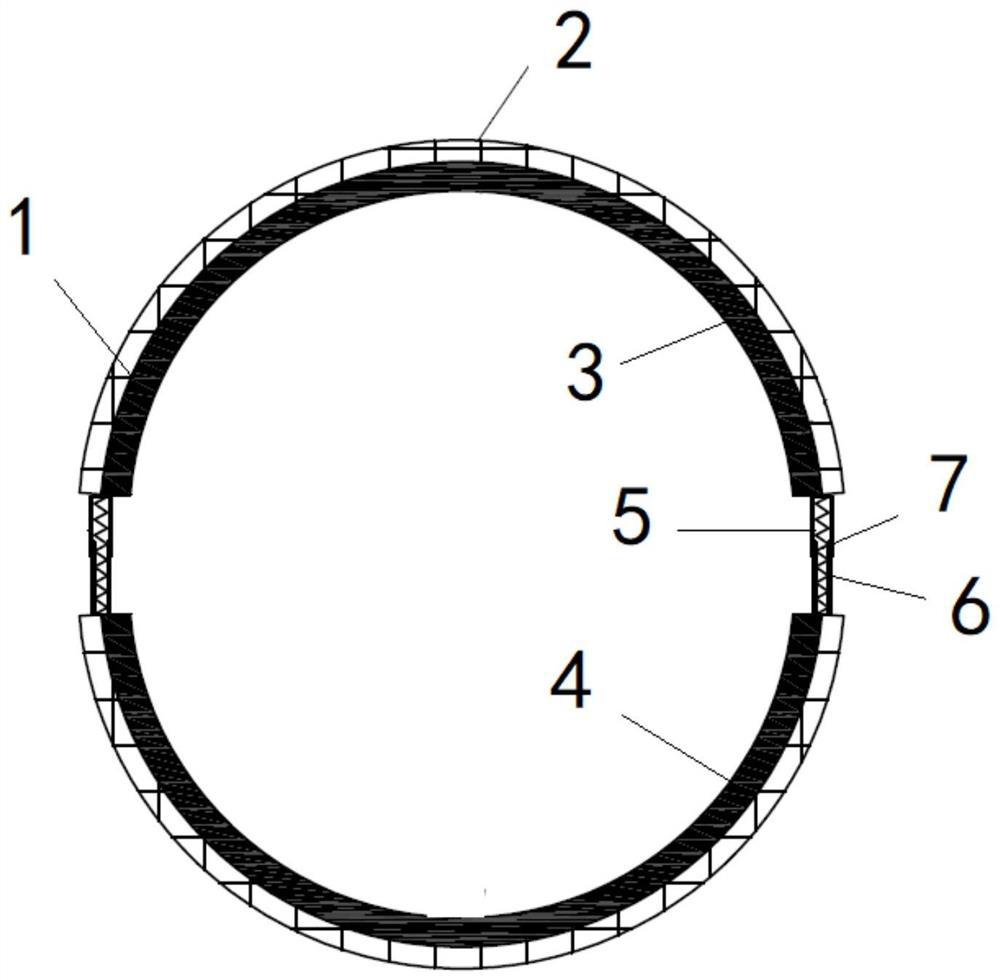

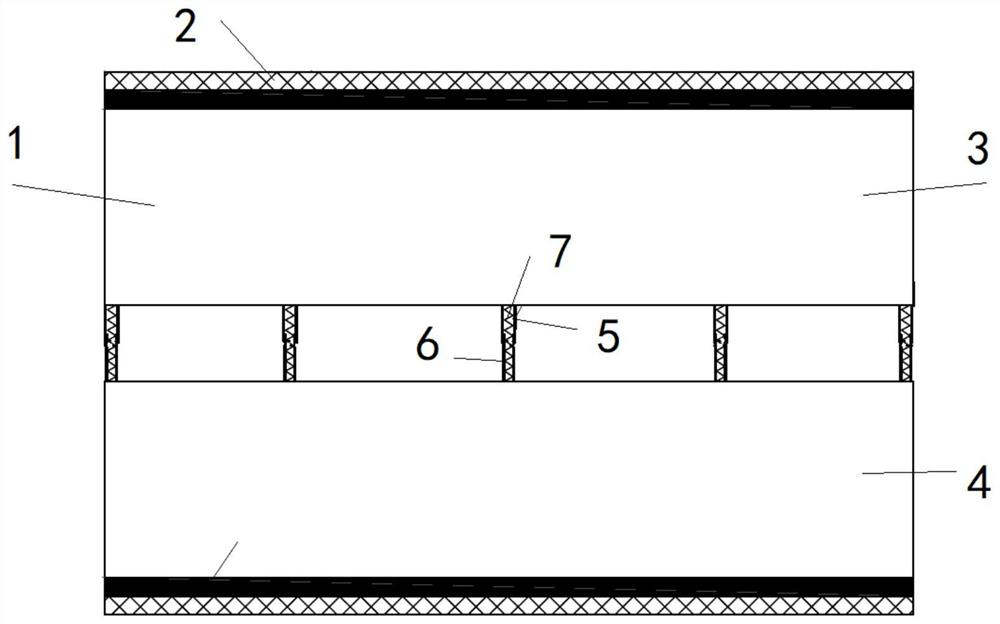

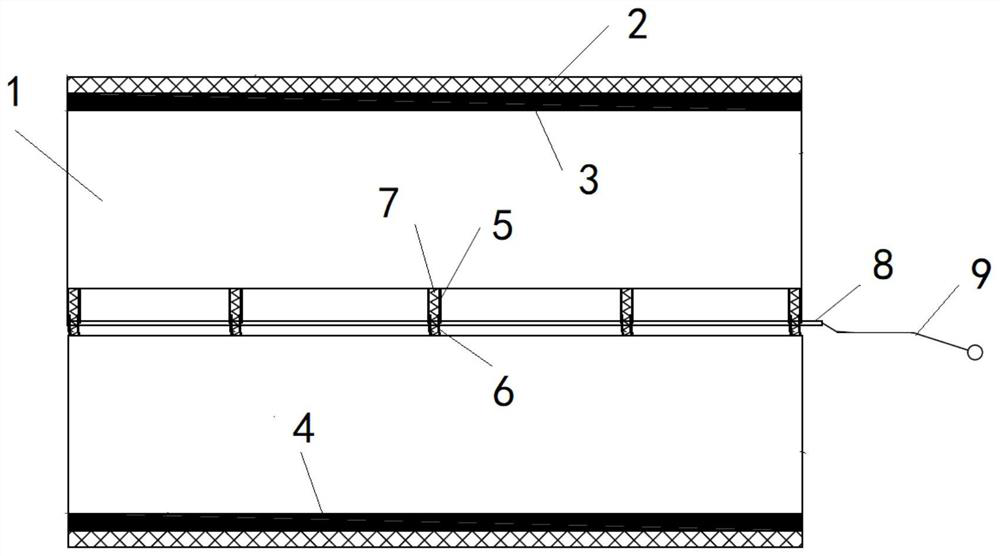

[0030] Embodiment 1: as figure 1 As shown, a pipe elastic plugging valve includes a plugging valve body 1, the plugging valve body 1 is an arc-shaped structure, its outer diameter is compatible with the inner diameter of the pipeline to be repaired, and its radial dimension can be contracted or Zoom in, the plugging valve body 1 is provided with a retractable or expandable elastic mechanism and a retractable locking mechanism, and the outer layer of the plugging valve body 1 is coated with an anti-seepage cushion layer 2; Compatibility means that the outer diameter of the arc-shaped structure of the plugging valve body 1 is smaller than the inner diameter of the pipeline to be repaired after contraction, and can rely on the expansion force of the elastic mechanism of the device to expand the inner diameter and press tightly against the pipe to be repaired after being opened. Repair the inner surface of the pipeline, and use the anti-seepage pad 2 of the outer layer to block th...

Embodiment 2

[0034] Embodiment 2: The plugging valve body 1 is made of a non-closed quasi-spiral high-elasticity steel plate 11, the quasi-spiral-shape high-elasticity steel plate 11 is rolled into shape and heat-treated to make its outer diameter larger than that in the free state. The inner diameter of the pipeline to be repaired, the quasi-spiral-shaped high-elasticity steel plate 11 elastically deforms and shrinks under the action of external pressure and closes, and the outer diameter is smaller than the inner diameter of the pipeline to be repaired, and the openings are staggered and superimposed; the two edges of the opening are provided with a retractable locking mechanism The retractable locking mechanism includes at least two superimposed coaxial lugs 10 fixedly connected to the two edges of the opening of the quasi-spiral high-elasticity steel plate 11, and two lugs 10 corresponding to the upper and lower edges. A pair of locks, all the through holes of each pair of locks are ins...

Embodiment 3

[0038] Embodiment 3: The plugging valve body is made of a non-closed quasi-cylindrical high-elastic steel plate 12 that is rolled up similar to Embodiment 2, but one side of the opening is provided with a step 13 using an inwardly turning structure. All the other structures, materials and techniques are the same as in Example 2. The quasi-cylindrical high-elastic steel plate can make the roundness better after the locking mechanism is released, and its elastic force is much greater than that of the coil spring, which is more conducive to fitting and adapting to the shape of the pipeline to be repaired. see Figure 6 , Figure 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com