Backpressure-free liquid return system and high-flow plunger pump

A back pressure-free, plunger pump technology, used in fluid pressure actuation system testing, piping systems, components of pumping devices for elastic fluids, etc. Liquid resistance along the way, the influence of the normal operation of the hydraulic support, etc., to ensure the normal return of liquid and work, to overcome the resistance along the way.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-5 The application is described in further detail.

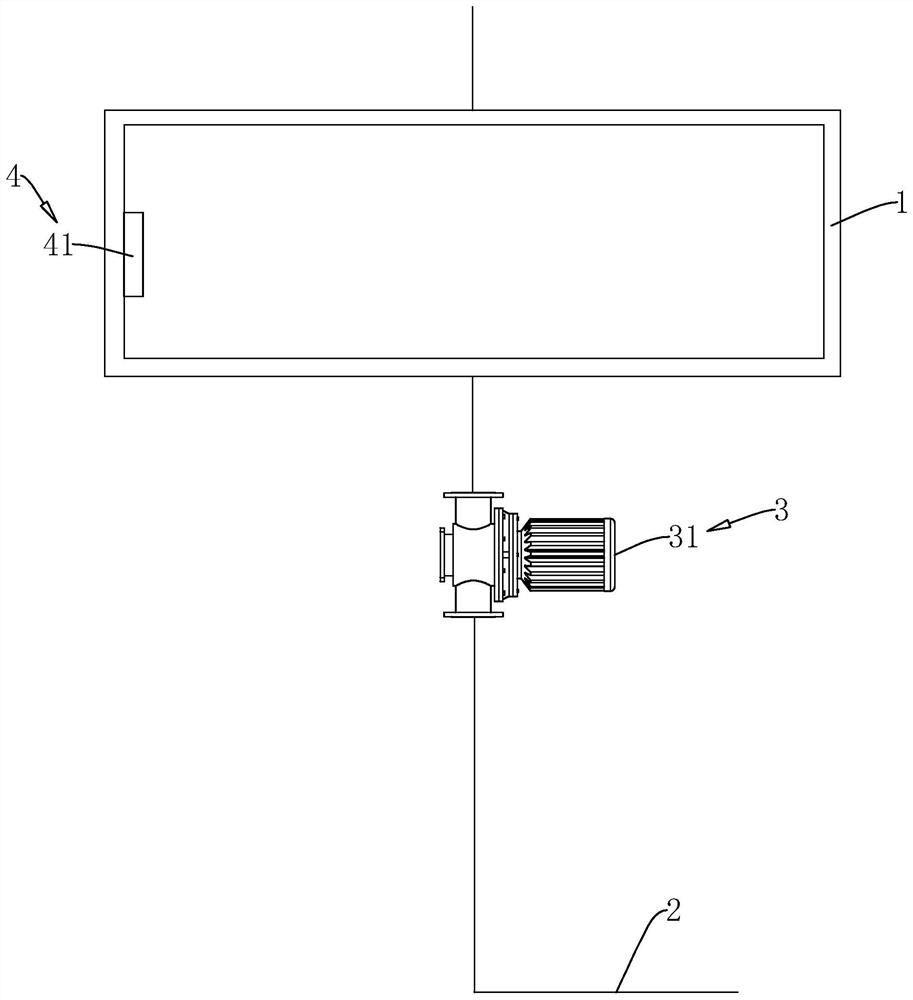

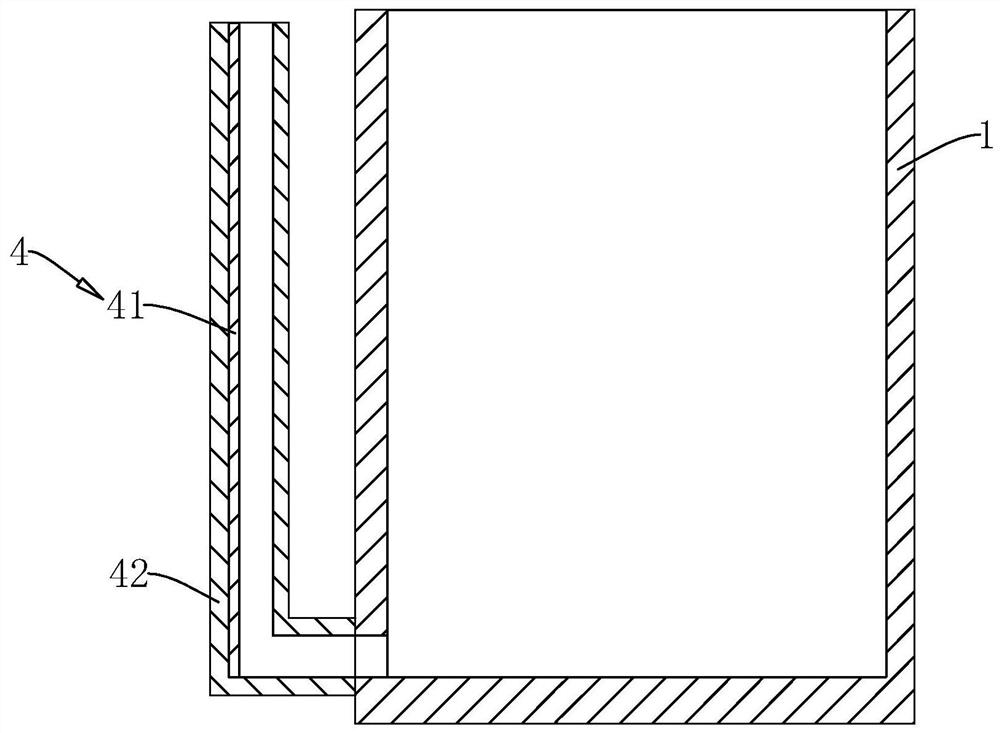

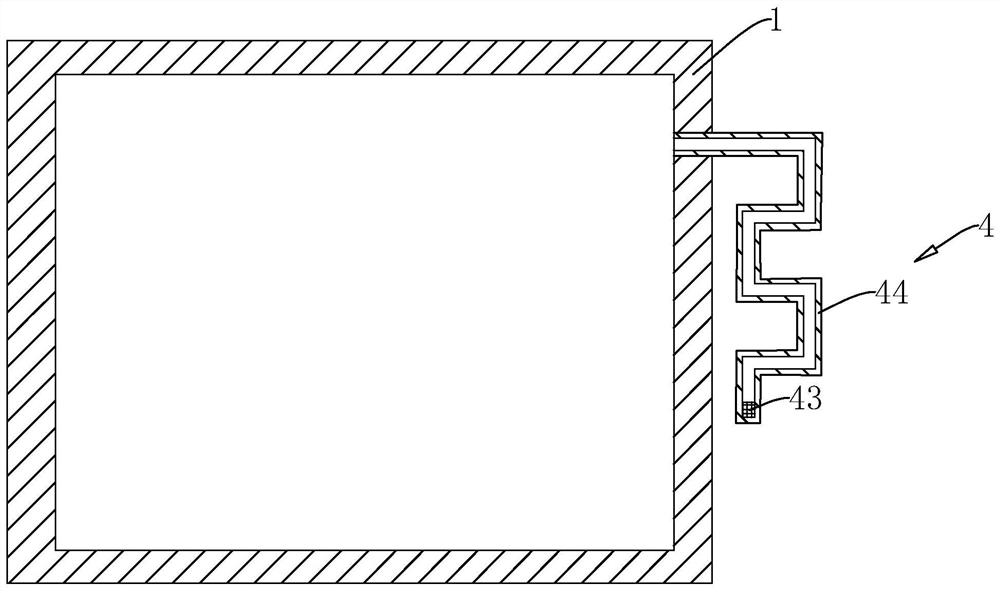

[0036] The embodiment of the present application discloses a liquid return system without back pressure. refer to figure 1 , the liquid return system includes a liquid return tank 1 arranged at the liquid outlet of the hydraulic support for collecting the emulsion flowing out of the hydraulic support, a liquid return pipe 2 connected between the liquid return tank 1 and the emulsion pump station, and a set The liquid return pipe 2 is used to transport the emulsion in the liquid return tank 1 to the power unit 3 of the emulsion pump station through the liquid return pipe 2 . When in use, the emulsion flowing out from the hydraulic support can directly flow to the return tank 1 to be collected, and then the power unit 3 can provide power for the emulsion to flow back from the return tank 1 to the emulsion pump station, so that the emulsion can overcome The resistance along the way d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com