Method for making semiconductor device

A technology for semiconductors and devices, applied in the field of semiconductor devices and their manufacturing, can solve problems such as increasing the number of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, an embodiment of a method for manufacturing a semiconductor device according to the present invention will be described in detail with reference to related drawings.

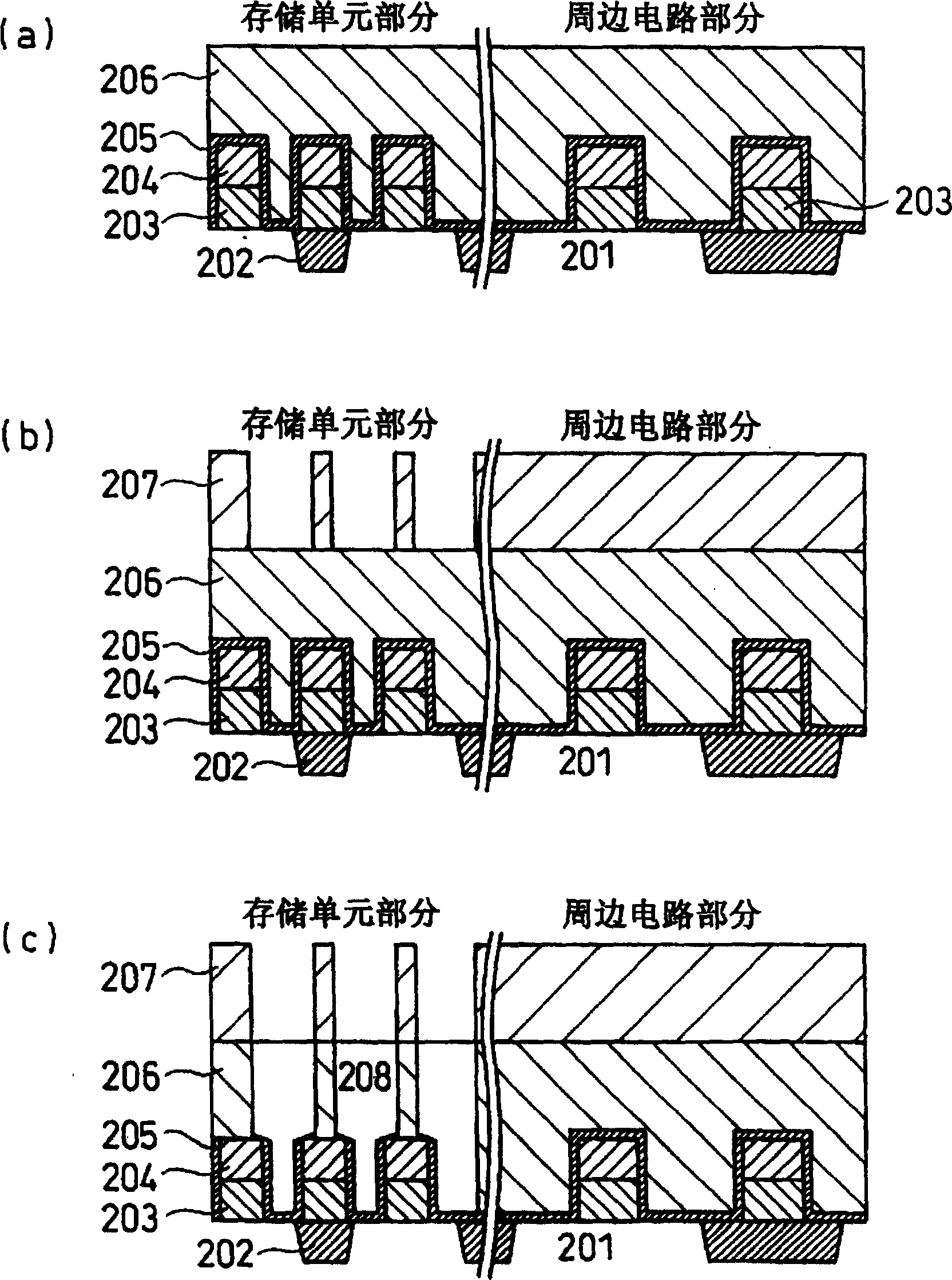

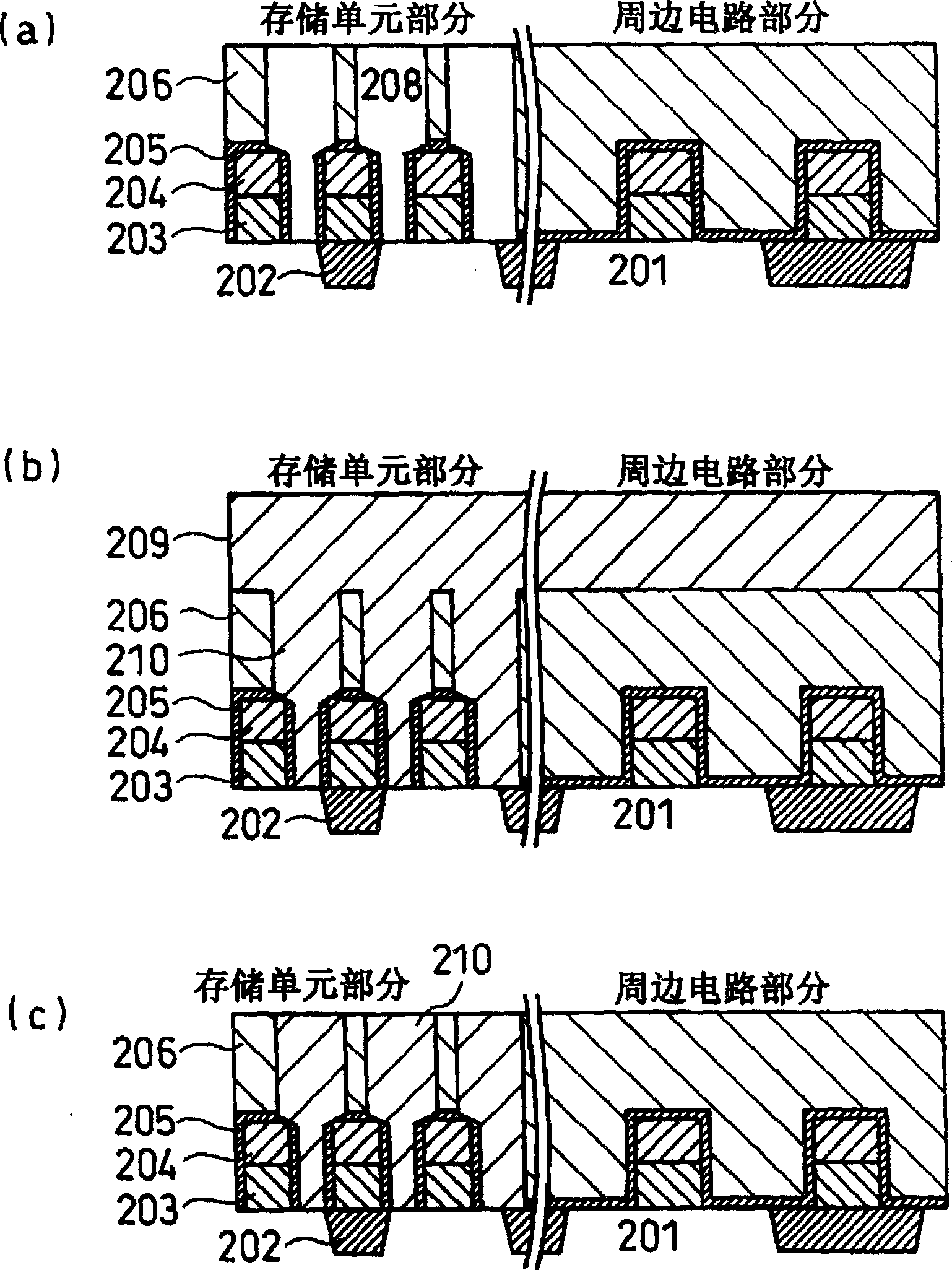

[0026] figure 2 Figure 6 A method of manufacturing a semiconductor device according to the present invention is shown.

[0027] In these drawings, figure 2 (a) represents a first step whereby a polysilicon film 203 and an insulating film 204 are formed on a semiconductor substrate 201, and then the polysilicon film 203 and the insulating film 204 are etched into a predetermined shape to form a gate electrode 203, and thereafter, the An etching stopper film 205 and an interlayer insulating film 206 are formed on the entire surface thereof.

[0028] figure 2 (c) represents a second step whereby a contact hole 208 reaching the semiconductor substrate is formed in the interlayer insulating film 206 so as to expose the etching stopper film 205 on the semiconductor substrate.

[0029] im...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap