Substrate combining structure, substrate combining system and substrate combining method

A splicing system and substrate technology, applied in the structural connection of printed circuits, printed circuits, lithography/patterns, etc., can solve the problem that circuit boards cannot be spliced with circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

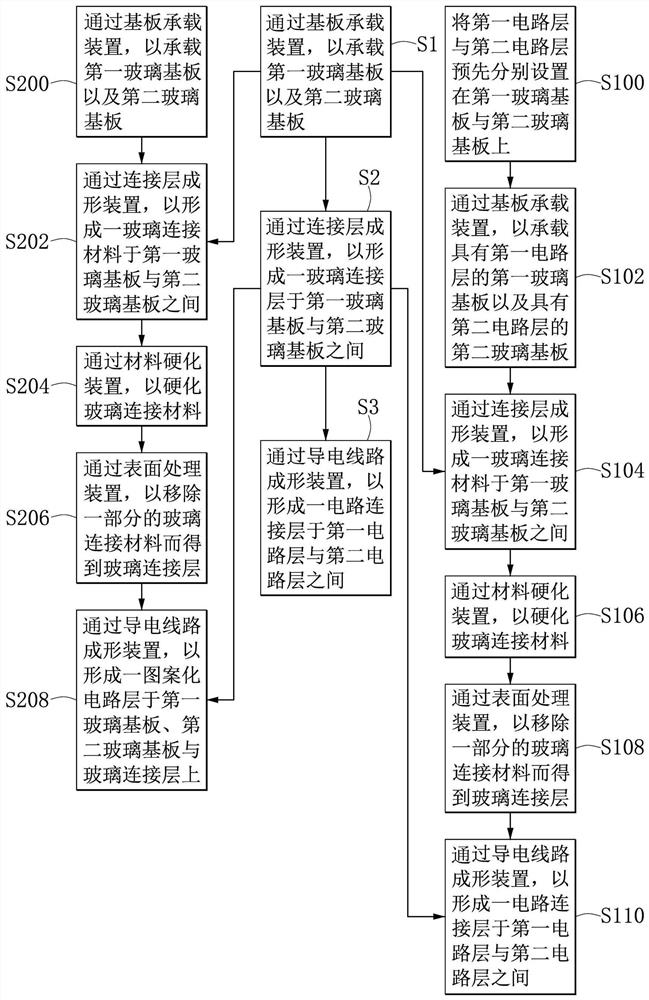

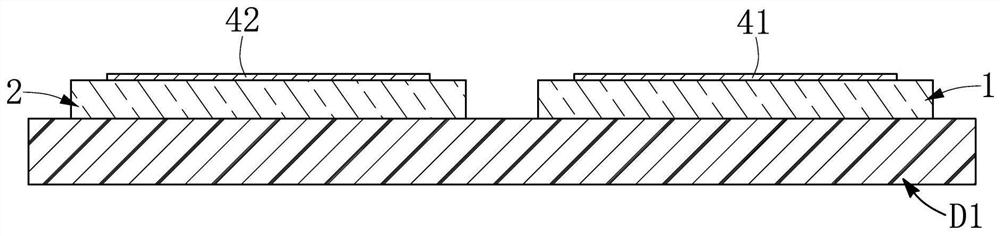

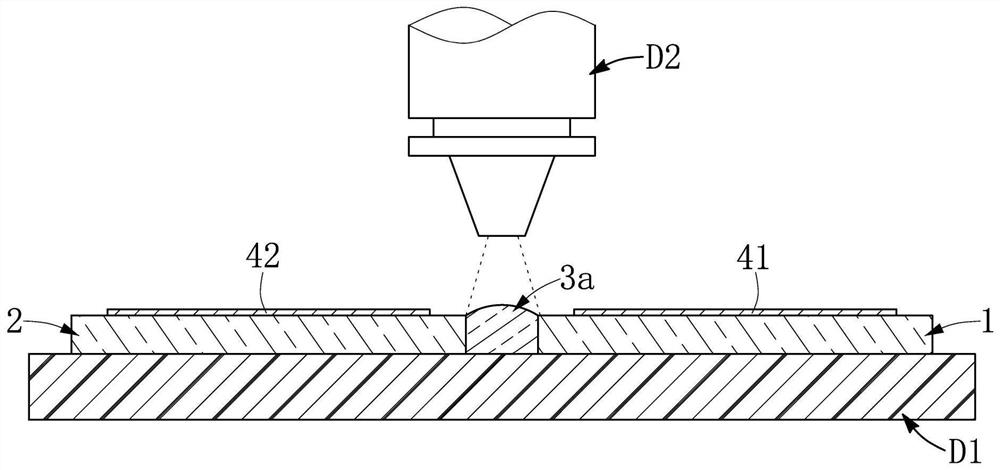

[0038] refer to Figure 1 to Figure 6 As shown, the first embodiment of the present invention provides a substrate splicing method, which includes: first, cooperate figure 1 and figure 2 As shown, a first circuit layer 41 and a second circuit layer 42 are respectively pre-disposed on a first glass substrate 1 and a second glass substrate 2 (step S100); then, cooperate figure 1 and figure 2 As shown, a substrate carrying device D1 is used to carry the first glass substrate 1 with the first circuit layer 41 and the second glass substrate 2 with the second circuit layer 42 (step S102); then, cooperate figure 1 and image 3 As shown, a connecting layer forming device D2 is used to form a glass connecting material 3a between the first glass substrate 1 and the second glass substrate 2 (step S104); figure 1 and Figure 4 As shown, through a material hardening device D3, to harden the glass connection material 3a (step S106); figure 1 , Figure 4 and Figure 5 As shown, a s...

no. 2 example

[0047] Cooperate Figure 7 As shown, the second embodiment of the present invention provides a substrate splicing structure S, which includes: a first glass substrate 1, a second glass substrate 2, a glass connecting material 3a (unprocessed glass connecting layer) and a Jumper wire W. Depend on Figure 7 and Figure 6It can be seen that the biggest difference between the second embodiment of the present invention and the first embodiment lies in: after finishing the production of the glass connecting material 3a (as in the first embodiment image 3 and Figure 4 As shown), the jumper circuit W provided by the second embodiment can be directly connected to the first circuit layer 41 and the Between the second circuit layer 42 .

no. 3 example

[0049] refer to figure 1 as well as Figure 8 to Figure 12 As shown, the second embodiment of the present invention provides a substrate splicing method, which includes: first, cooperate figure 1 and Figure 8 As shown, a substrate carrying device D1 is used to carry a first glass substrate 1 and a second glass substrate 2 (step S200); then, coordinate figure 1 and Figure 9 As shown, a connecting layer forming device D2 is used to form a glass connecting material 3a between the first glass substrate 1 and the second glass substrate 2 (step S202); then, cooperate figure 1 and Figure 10 As shown, through a material hardening device D3, to harden the glass connection material 3a (step S204); Next, cooperate figure 1 , Figure 10 and Figure 11 As shown, a surface treatment device D4 is used to remove a part of the glass connecting material 3a to obtain the glass connecting layer 3 (step S206); figure 1 and Figure 12 As shown, a patterned circuit layer 4 is formed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com