Production method and system for improving yield of high-speed wire rod production line

A high-speed wire rod and production system technology, which is used in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problem that the head of the rolling piece cannot be rolled at low temperature, the product has poor passability, and the head and tail of the rolling piece cannot be rolled. Dimension difference and other problems, to achieve the effect of improving metal yield, saving manual shearing of head and tail links, and large spacing between rolling mills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

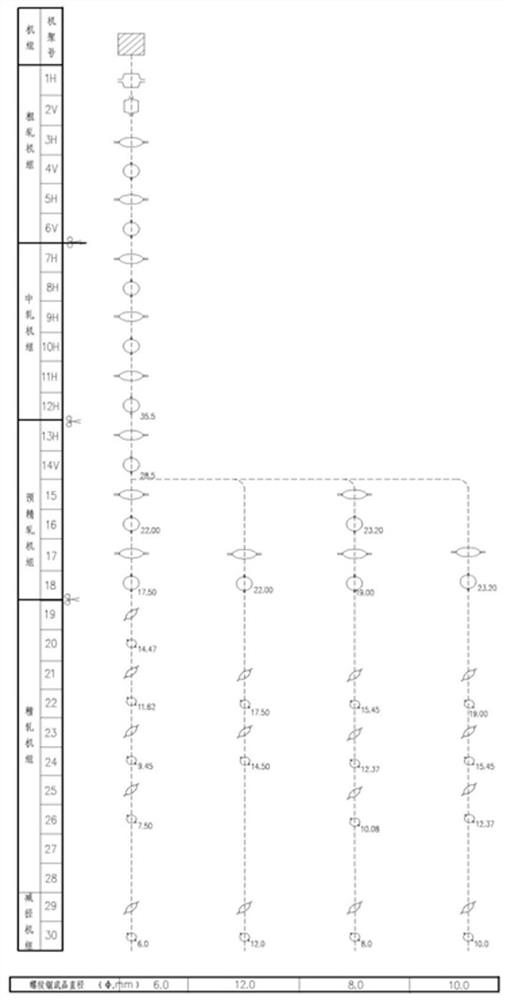

[0055] Such as figure 1 A production method and system for increasing the output of a high-speed wire rod production line as shown, including a heating furnace 1 for heating a steel billet, a rough rolling unit 2 for initially rolling the heated billet, and a head for the rough-rolled wire rod Flying shears for partial shearing after rough rolling 3. Intermediate rolling unit for secondary rolling of wire rods after rough rolling and flying shears 4. Intermediate rolling flying shears for tail shearing of wire rods after intermediate rolling 5. The pre-finishing rolling unit for three-time rolling of the wire rod after intermediate rolling flying shear 6, the pre-finishing cooling box for cooling the pre-finishing wire rod 7, the pre-finishing box for head and tail shearing of the cooled pre-finishing wire rod Finish rolling flying shear machine 8, finish rolling unit for fine rolling the pre-finish rolling wire rod after flying shear cooling 9, finish rolling cooling box 10 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com