Magnetic grinding device and method for bead-shaped inner spherical surface

A technology of magnetic grinding and inner spherical surface, applied in the direction of spherical grinding machine, grinding drive device, surface polishing machine tool, etc., can solve the problem of lack of processing device, etc., and achieve the effect of simple operation, good reliability and novel method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

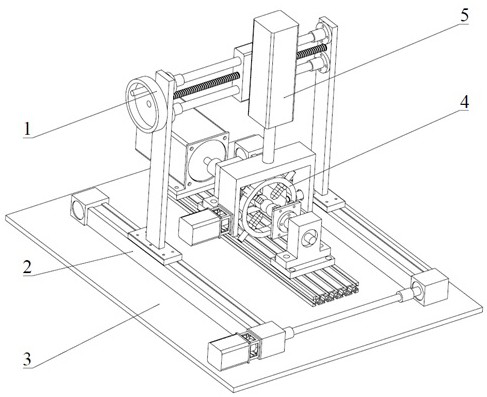

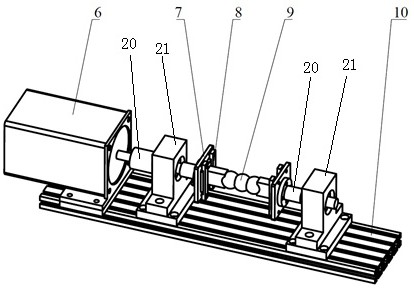

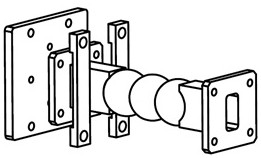

[0028] Such as Figure 1-4 Shown:

[0029] A magnetic grinding device for a beaded inner spherical surface, which includes a hand-operated screw system 1 (consisting of a hand wheel, a screw, a slider, a guide shaft, a shaft support, and a mounting frame, which is easy to purchase), a synchronous belt combination module Group 2 (composed of motors, guide rails, timing belts, etc., easy to purchase), workbench 3, swing magnetic field generator 4 (magnetic pole rings, support frames can be processed by ourselves, and magnet groups, bearings, and servo motors are easy to purchase), electric thrust Cylinder 5, speed regulating motor 6, mounting plate 7 (generally composed of two pieces, front and rear, to facilitate the clamping of workpieces, and can be designed according to different workpieces), pressure plate 8 (can be designed according to different workpieces, mainly used to The workpiece is clamped on the mounting plate, which is a general fixture), the workpiece 9, the pr...

Embodiment 2

[0032] Embodiment two. A magnetic grinding device and method for a beaded inner spherical surface, comprising the following steps:

[0033] 1) Fill the workpiece 9 with a certain amount of magnetic abrasive and grinding fluid, and clamp the workpiece 9 to one end of the speed-regulating motor 6 .

[0034] 2) Adjust the motor of the synchronous belt assembly module 2 so that the center of the magnetic pole ring on the swinging magnetic field generator 4 and the center of the spherical inner cavity of the workpiece are on the same vertical plane.

[0035]3) Adjust the handwheel of the hand-operated screw system 1 so that the center of the magnetic pole ring on the oscillating magnetic field generator 4 and the center of the spherical inner cavity of the workpiece are on the same vertical line.

[0036] 4) Adjust the electric thrust cylinder 5 so that the center of the magnetic pole ring on the swing-type magnetic field generator 4 coincides with the center of the inner spherica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com