High-performance core foamed concrete insulating brick and production process thereof

A foamed concrete, high-performance technology, used in other home appliances, applications, building materials, etc., can solve the problems of thermal insulation, poor compressive strength, and inability to meet, and achieve good compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

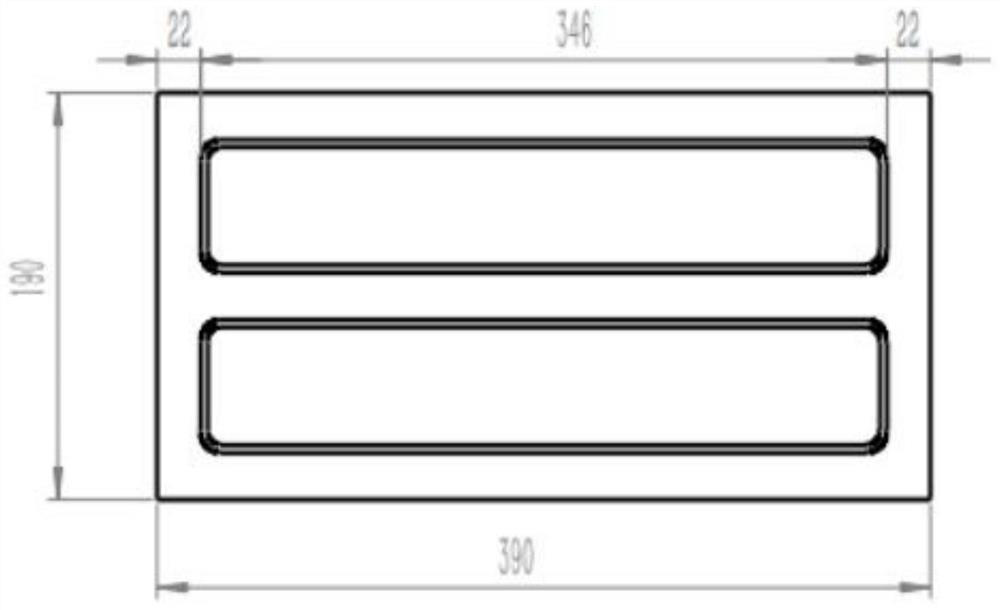

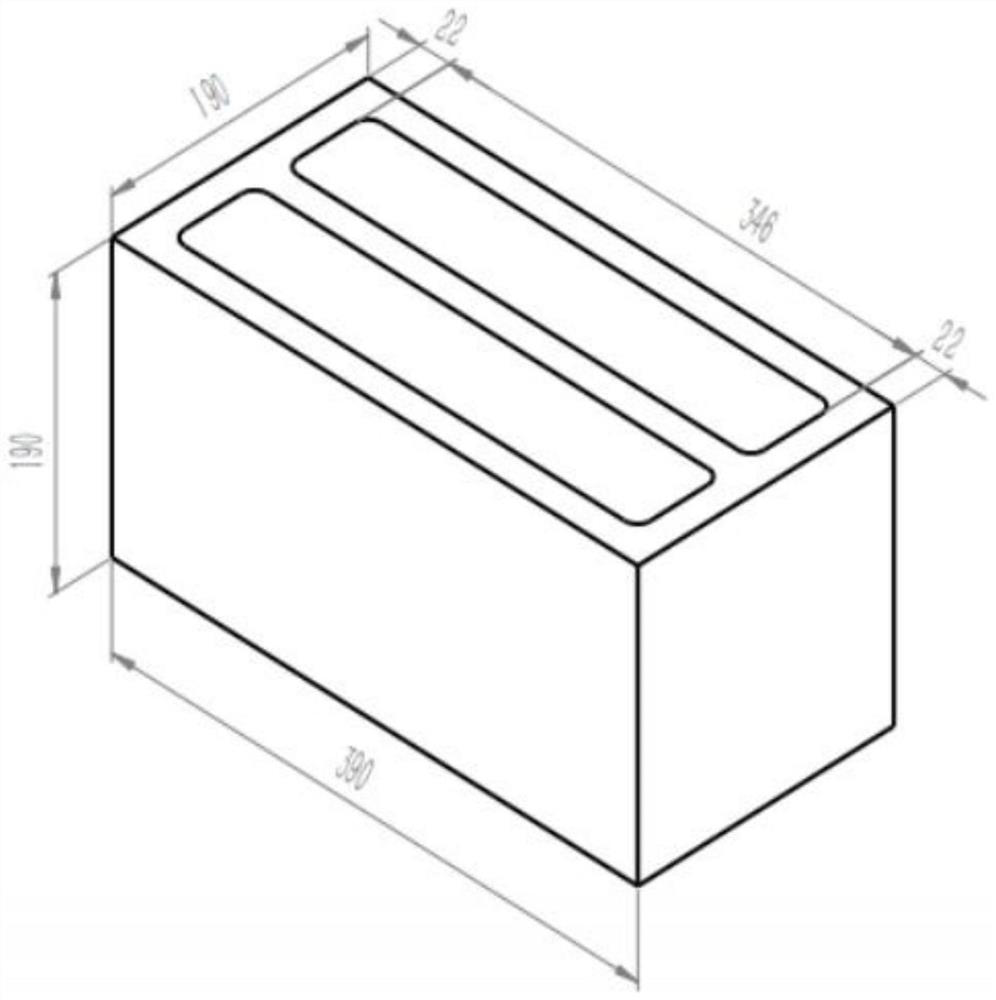

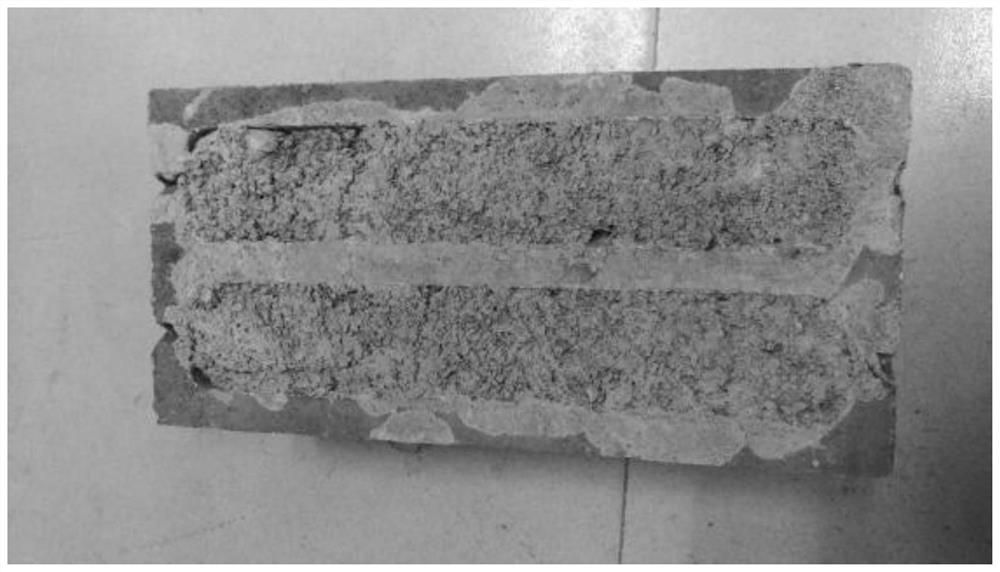

[0046] A high-performance core foamed concrete insulation brick, including a hollow brick as a brick shell (see figure 1 , figure 2, specification is 390mm * 190mm * 190mm) and the core cell foam concrete filled in the cavity of the brick body, in parts by weight, the core cell foam concrete includes the following materials: 72 parts of cement, 3.4 parts of calcium chloride 2.6 parts of aluminum sulfate, 4.3 parts of sodium sulfate, 14 parts of hydrogen peroxide, 2.5 parts of water reducing agent, 0.5 parts of foaming agent, 0.2 parts of foam regulator, 0.2 parts of foam stabilizer, 2 cyclohexyl peroxydicarbonate 3 parts, 3 parts of 3-N-tert-butoxycarbonylaminocyclobutylamine, 1.2 parts of 2,2-dihydropropane peroxide, 4.2 parts of sodium starch octyl succinate, 380 parts of water;

[0047] Described cement is portland cement;

[0048] The mass concentration of described hydrogen peroxide is 25%;

[0049] The water reducing agent is naphthalenesulfonate formaldehyde condens...

Embodiment 2

[0061] A high-performance core foamed concrete insulation brick, including a hollow brick as a brick shell (see figure 1 , figure 2 , specification is 390mm * 190mm * 190mm) and the core cell foamed concrete filled in the cavity of the brick body, in parts by weight, the core cell foamed concrete includes the following materials: 62 parts of cement, 3 parts of calcium chloride 2 parts, 2 parts of aluminum sulfate, 4 parts of sodium sulfate, 11 parts of hydrogen peroxide, 2 parts of water reducer, 0.3 parts of foaming agent, 0.1 part of foam regulator, 0.2 parts of foam stabilizer, 1 part of dicyclohexyl peroxydicarbonate 2 parts, 2 parts of 3-N-tert-butoxycarbonylaminocyclobutylamine, 0.9 parts of 2,2-dihydropropane peroxide, 3 parts of sodium starch octyl succinate, 330 parts of water;

[0062] Described cement is portland cement;

[0063] The mass concentration of the hydrogen peroxide is 23%;

[0064] The water reducing agent is naphthalenesulfonate formaldehyde condens...

Embodiment 3

[0076] A high-performance core foamed concrete insulation brick, including a hollow brick as a brick shell (see figure 1 , figure 2 , specification is 390mm * 190mm * 190mm) and the core cell foamed concrete filled in the cavity of the brick body, in parts by weight, the core cell foamed concrete includes the following materials: 78 parts of cement, 4 parts of calcium chloride 3 parts, 3 parts of aluminum sulfate, 5 parts of sodium sulfate, 15 parts of hydrogen peroxide, 3 parts of water reducer, 0.6 parts of foaming agent, 0.2 parts of foam regulator, 0.3 parts of foam stabilizer, 3 parts of dicyclohexyl peroxydicarbonate 4 parts of 3-N-tert-butoxycarbonylaminocyclobutylamine, 1.4 parts of 2,2-dihydropropane peroxide, 5 parts of sodium starch octyl succinate, 390 parts of water;

[0077] Described cement is portland cement;

[0078] The mass concentration of the hydrogen peroxide is 27%;

[0079] The water reducing agent is naphthalenesulfonate formaldehyde condensation p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| loss rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com