Delinting assembly of high-yield sawtooth delinting machine

A sawtooth peeling machine, high-yield technology, applied in the direction of separating plant fibers from seeds, etc., can solve the problems of increasing the volume of the work box, device blockage, shrinking, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

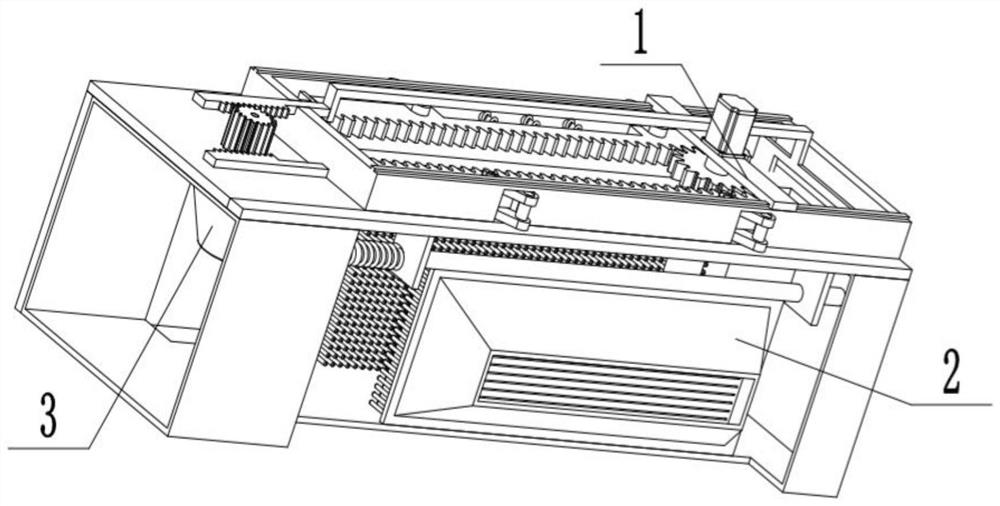

[0020] Example: such as figure 1 The high-yield sawtooth stripping machine velvet assembly shown includes a reversing device, a cotton doffer, and a cotton output device. The reversing device is vertically and fixedly installed on the ground to provide an installation platform for other devices. The cotton devices are all fixedly installed inside the reversing device. The reversing device can realize the rapid reversing movement of the doffer. The doffer is used to separate the cotton shell from the cotton, and the cotton output device is used to take out the detached cotton.

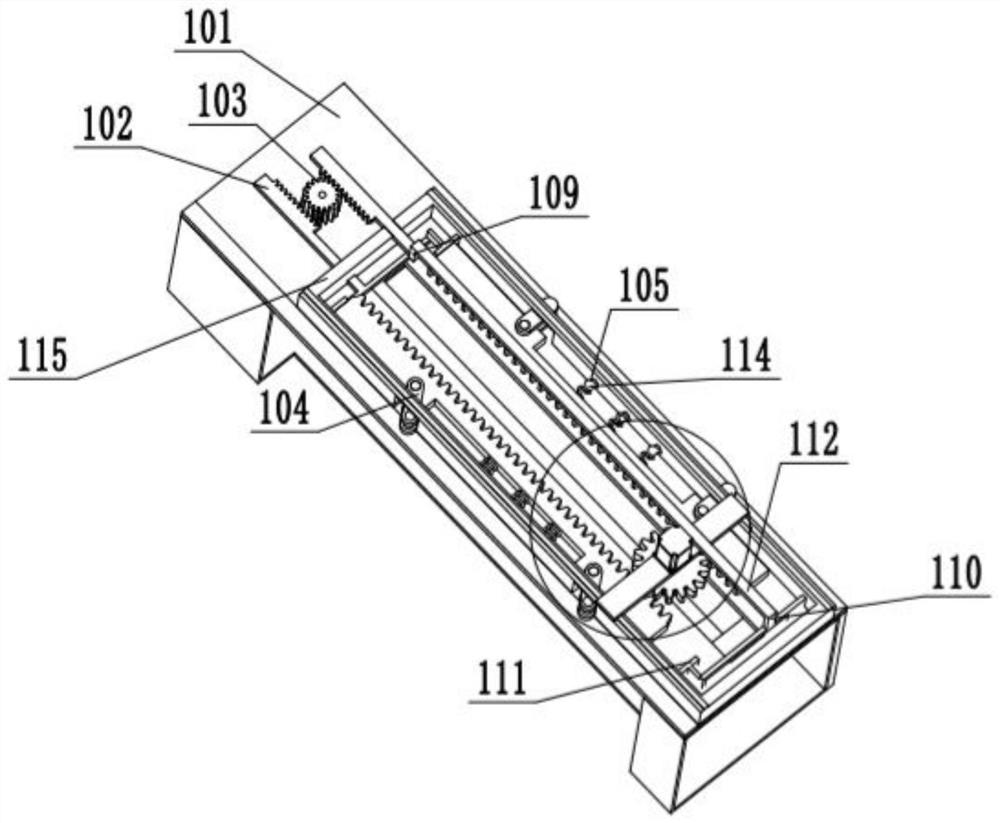

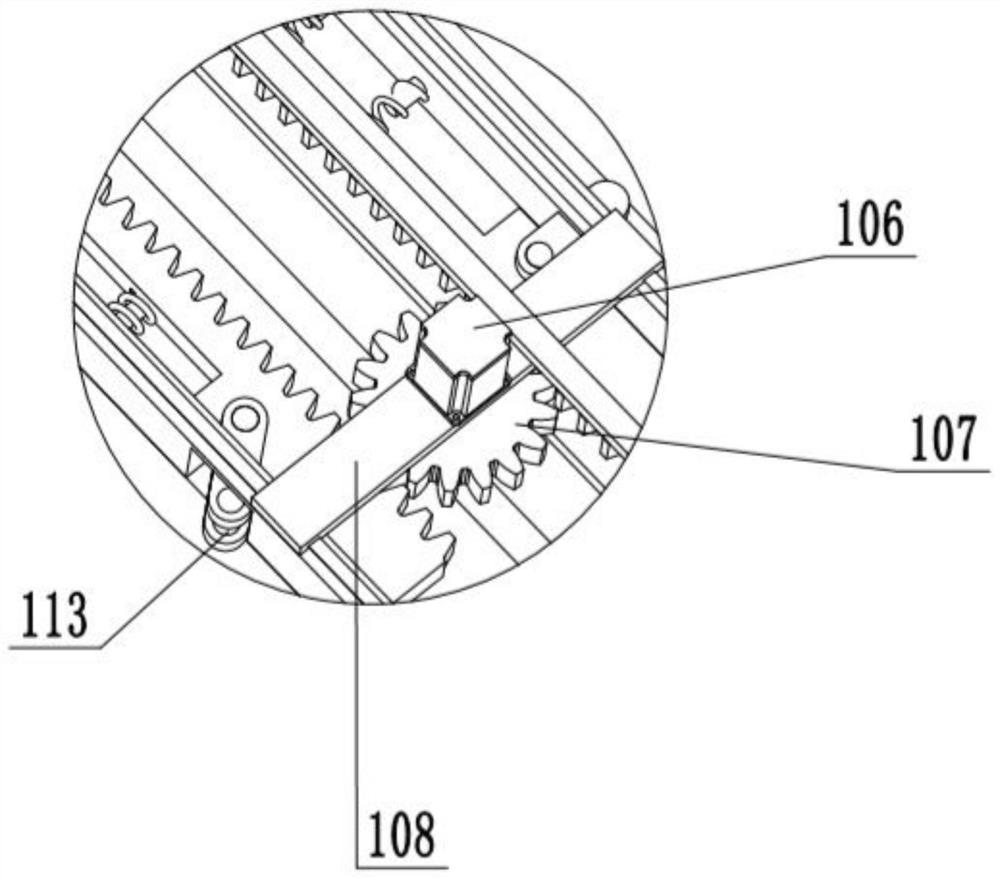

[0021] Such as figure 2 , image 3 The shown reversing device 1 includes a housing 101, a reversing rack 102, a spur gear 103, a rack splint 104, a return spring 105, a driving motor 106, a reversing spur gear 107, a limit push plate 108, a forward Limiting block 109, reverse limiting block 110, rack push plate 111, limiting block connecting plate 112, fixed shaft 113, installation shaft 114, chute p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com