System and method for drying anti-curl paper through steam introduction in different cylinders and layers after gluing

An anti-curling paper and cylinder separation technology, applied in the field of papermaking, can solve problems such as excessive deviation of water absorption added value and curling of finished paper, achieve uniform distribution of water molecules, and solve the effect of easy warping and wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

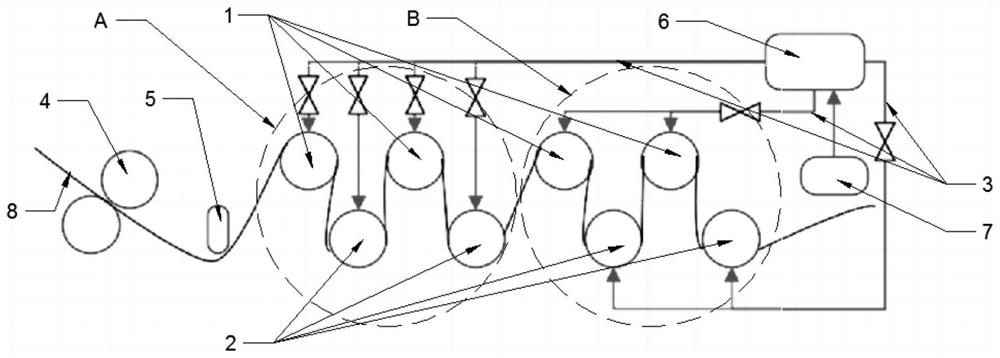

[0028] see figure 1 , the anti-curling paper system provided in this embodiment after gluing is divided into cylinders and layered with steam, and the drying mechanism includes a first surface drying mechanism 1 and a second surface drying mechanism 2, and the first surface drying mechanism is The mechanism 1 and the second surface drying mechanism 2 are respectively arranged on the first surface side and the second surface side of the paper from the glue machine 4, and are used to dry the two sides of the paper in sequence.

[0029] Both the first surface drying mechanism 1 and the second surface drying mechanism 2 use a drying cylinder, which is connected with a steam main pipe 3 that provides heat for the drying cylinder. The drying cylinder can be rolled, and the paper is wound on the surface of the drying cylinder. Rolling facilitates paper movement.

[0030] The first surface drying cylinder of the first surface drying mechanism 1 and the second surface drying cylinder ...

Embodiment 2

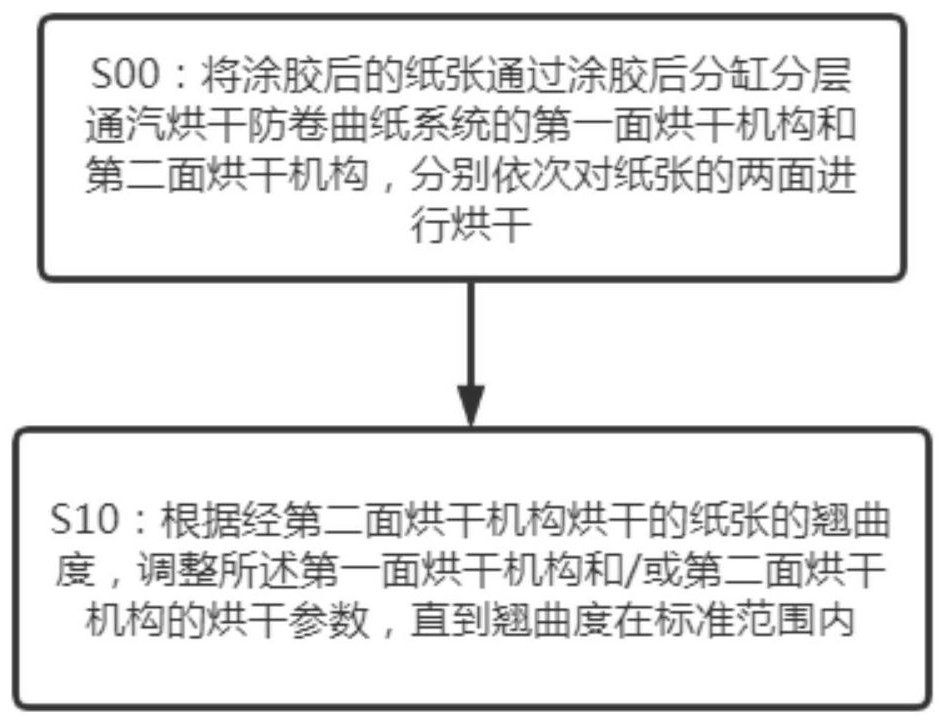

[0037] see figure 2 , the present embodiment provides a process for drying the anti-curl paper in separate cylinders and layered steaming after gluing, including the following steps:

[0038] S00: Pass the glued paper through the first-side drying mechanism and the second-side drying mechanism of the anti-curling paper system of the layered steam drying anti-curl paper system after glueing in Example 1, and then sequentially dry both sides of the paper. Drying; in this embodiment, since the first surface drying mechanism 1 and the second surface drying mechanism 2 each include 4 drying cylinders, the paper first passes through the first surface drying cylinder of the upper layer to dry the paper at the paper input end. One side, then dry the second side of the paper through the first second side dryer on the lower layer, then dry the first side of the paper through the second first side dryer on the upper layer, and then dry the paper through the second second side dryer on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com