Industrial waste gas emission monitoring method and system, terminal and storage medium

A technology of industrial waste gas and monitoring terminals, which is applied in the direction of electrical components, 2D image generation, telemetry/remote control selection devices, etc., can solve the problems of increasing labor intensity, save labor intensity, reduce the possibility of detection, and reduce labor intensity. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The application will be described in further detail below in conjunction with all the accompanying drawings.

[0068] The embodiment of the present application discloses a method for monitoring industrial waste gas discharge.

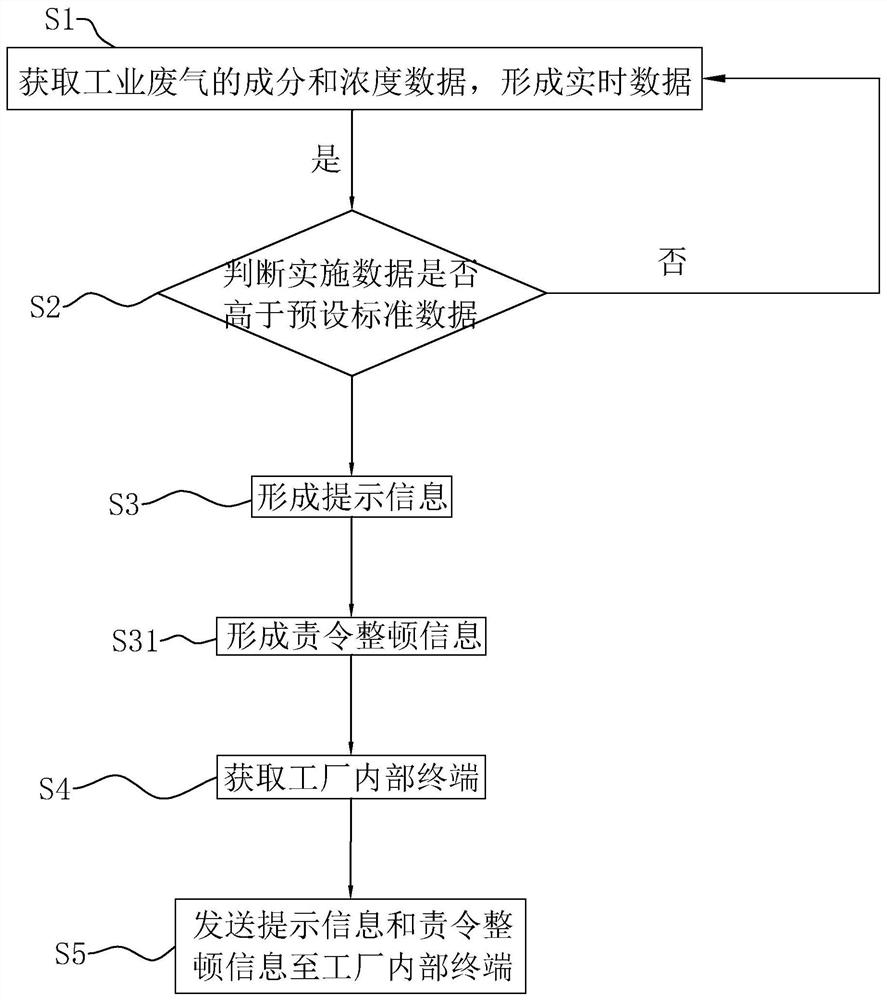

[0069] refer to figure 1 , S1: Obtain the data of the composition and concentration of the factory exhaust gas, and form real-time data.

[0070] Specifically, by installing a gas detection device in the factory, for example, the gas detection device is a gas detector, which is used to detect the composition and concentration data of the exhaust gas emitted by the factory.

[0071] S2: Judging whether the implementation data is higher than the preset standard data.

[0072] If the judgment is yes, jump to S3.

[0073] If the judgment is no, continue to execute S1.

[0074] Among them, the preset standard data is entered in advance by the personnel of the environmental protection department, and the preset standard data is different for differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com