Method for real-time industrial control passive identification of Rokwell equipment

A technology of Rockwell and equipment, applied in the field of real-time industrial control passive identification of Rockwell equipment, can solve the problems of affecting main network communication, main network attack, and untargeted accurate identification method of Rockwell equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

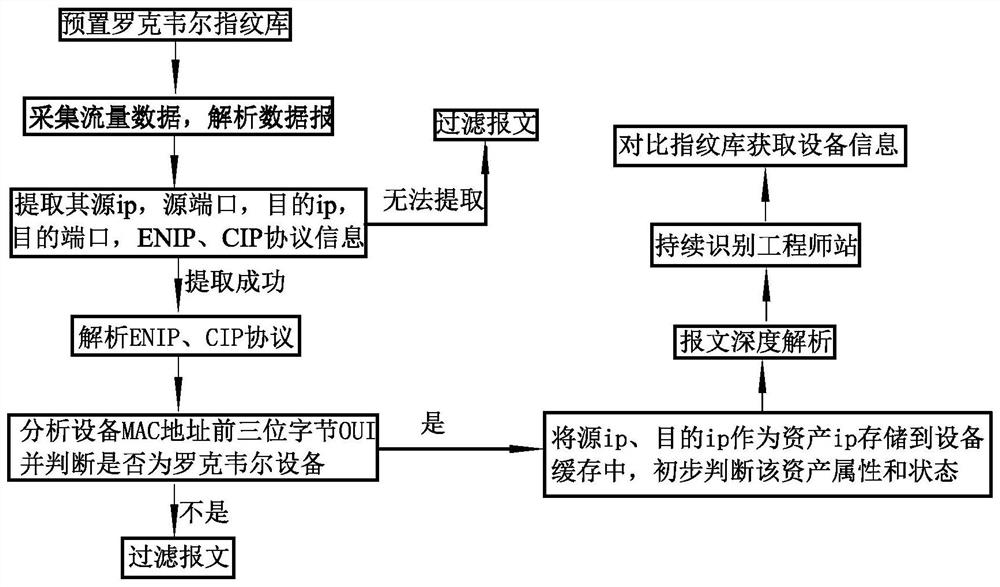

[0064] A real-time method for industrial control to passively identify Rockwell equipment, such as figure 1 shown, including the following steps:

[0065] ⑴Preset Rockwell fingerprint library;

[0066] (2) Preliminary analysis of messages: collect traffic data in the network environment, analyze datagrams, extract source ip, source port, destination ip, destination port, ENIP, CIP protocol information; if the above information cannot be extracted, it means that the message has no valid information , filter the message, and do not continue to process the message;

[0067] (3) Backup of basic equipment information: analyze the ENIP and CIP protocols, and determine whether the equipment is a Rockwell equipment by analyzing the first three bytes OUI of the MAC address of the equipment:

[0068] If so, store the source ip and destination ip as asset ip in the device cache, and preliminarily judge that the asset belongs to Rockwell PLC and Rockwell operator station according to th...

Embodiment 2

[0074] Adopt the method for the real-time industrial control passive identification Rockwell equipment of embodiment 1, wherein the specific process of step (1) preset Rockwell fingerprint storehouse is:

[0075] Extract key information from all Rockwell devices in the public network, encode the types and series of these devices, set rules for matching message application layer information, and form a fingerprint library.

Embodiment 3

[0077] Adopt the method for the real-time industrial control passive identification Rockwell equipment of embodiment 1, wherein the specific process of step (1) preset Rockwell fingerprint storehouse is:

[0078] Extract key information from all Rockwell devices in the public network, encode the types and series of these devices, set rules for matching message application layer information, and form a fingerprint library;

[0079] The specific operation steps of step ⑶ are:

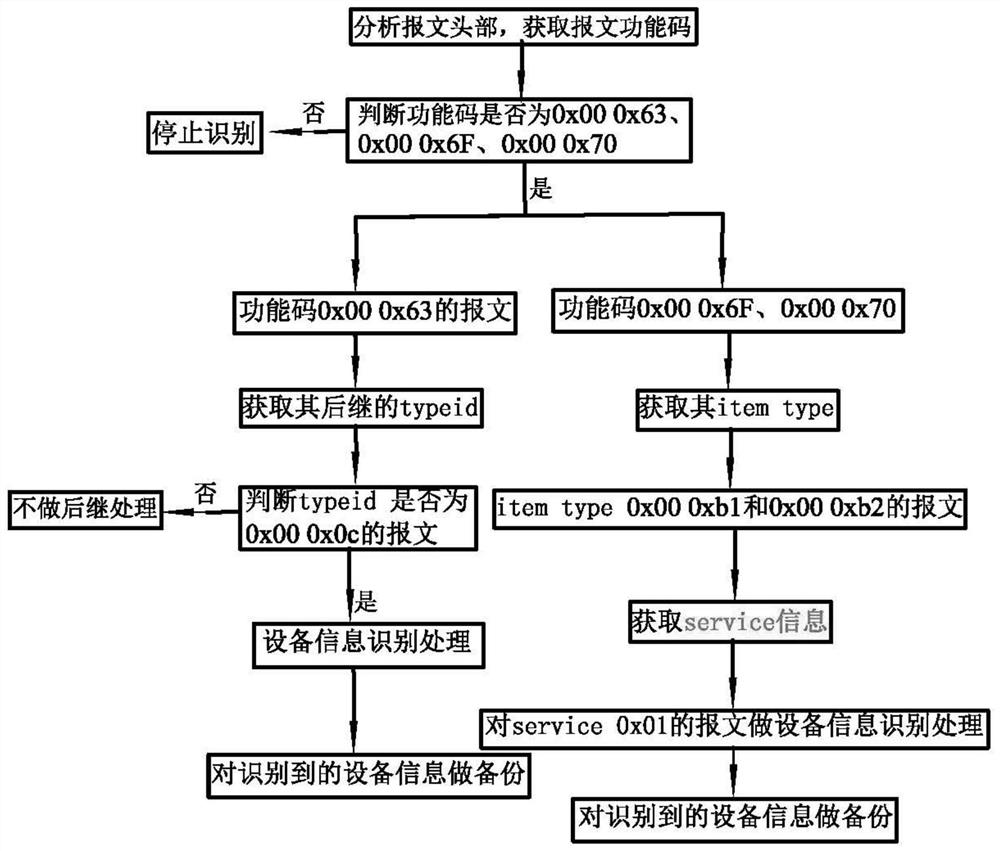

[0080] Preliminary analysis of the first two bytes of the application layer of the ENIP protocol. If these two bytes belong to the Rockwell command, and the source or destination port in the message is 44818, it means that there is a Rockwell device in the message. The flow generated by the operation; the ip corresponding to port 44818 in the message is Rockwell PLC, and the other ip is tentatively designated as the Rockwell operator station; if the operation flow is recognized at the same time, it means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com