High-strength energy-saving compartment flower barrier of stake truck or semitrailer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In this embodiment, according to the top size of a semi-trailer compartment, a hollow square tube made of stainless steel is used as the base material to cut the upper frame, lower frame and mullion of the fence frame. Both ends of the hollow square tube are cut with straight openings. Cut 30 pipes at the same time; the length of the upper frame and the lower frame is 4 meters, and the length of the mullion is 1.8 meters. The steel sheet base material made of stainless steel is directly processed by a progressive die to produce an integrated fully enclosed reinforced corner piece.

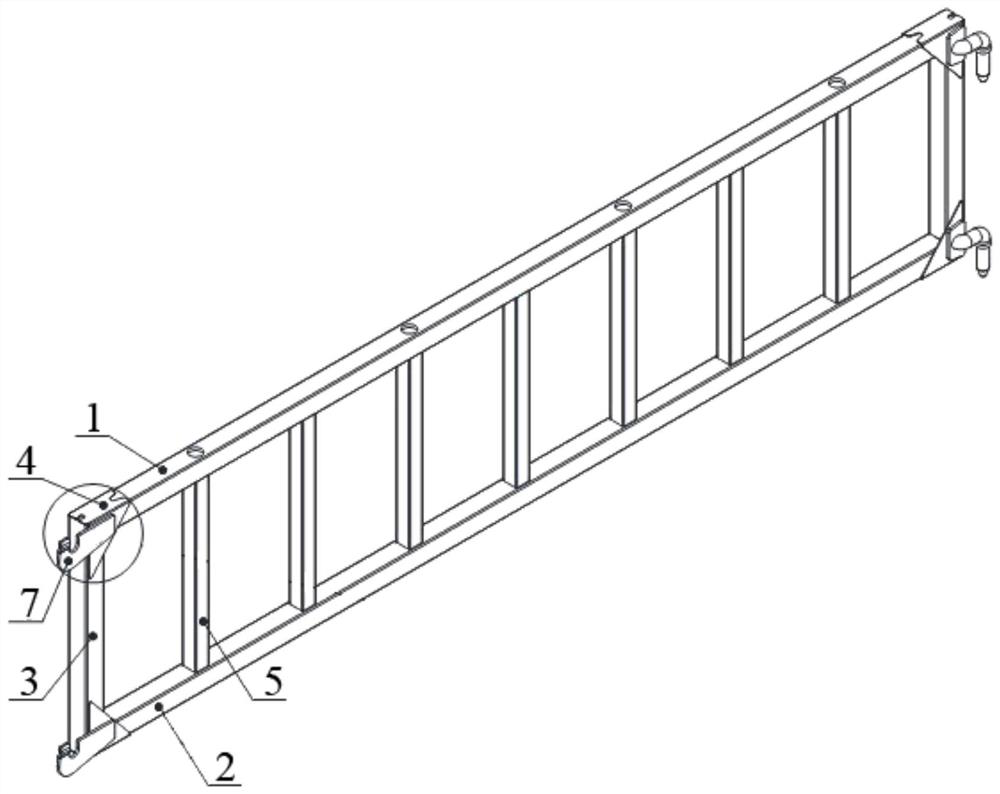

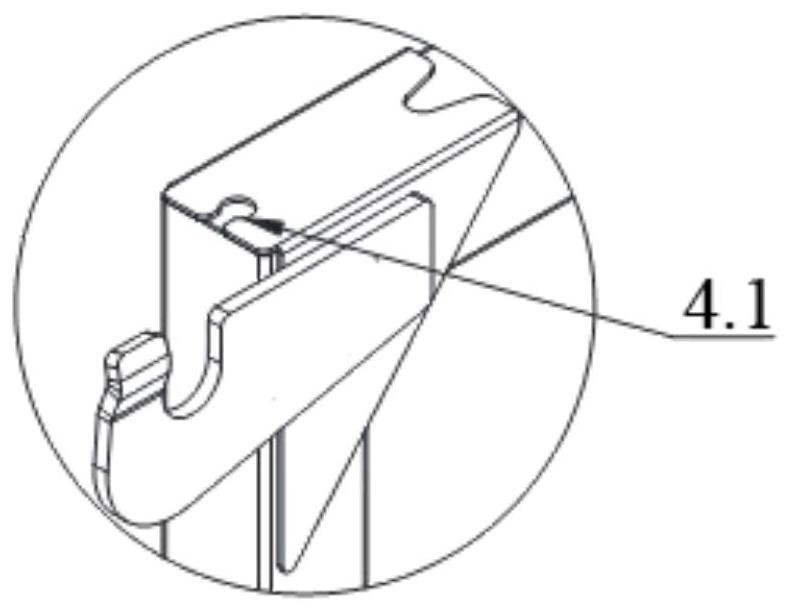

[0055] A high-strength energy-saving car railing for a warehouse-type truck or a semi-trailer, such as Figure 1-13 As shown, the fence frame includes an upper frame 1, a lower frame 2, a mullion 3, a reinforced corner piece 4, a vertical scale 5, a hinge 6 and a door knife 7;

[0056] The two ends of the upper frame 1 are respectively fixedly welded to the upper end sides of the two mullio...

Embodiment 2

[0070] In this embodiment, according to the top size of a semi-trailer compartment, a hollow square tube made of stainless steel is used as the base material to cut the upper frame, lower frame and mullion of the fence frame. Both ends of the hollow square tube are cut with straight openings. Cut 40 pipes at the same time; the length of the upper frame and the lower frame is 4.5 meters, and the length of the mullion is 2 meters. The steel sheet base material made of stainless steel is directly processed by a progressive die to produce an integrated fully enclosed reinforced corner piece.

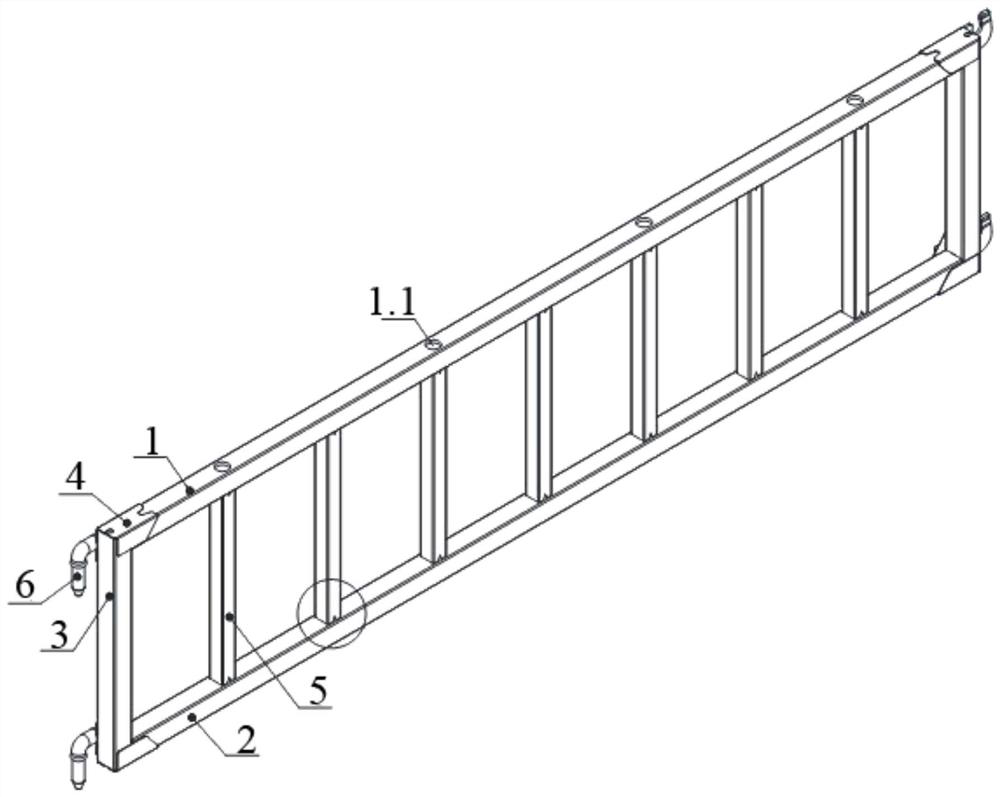

[0071]A high-strength energy-saving railing frame for a warehouse-type truck or a semi-trailer. The railing frame includes an upper frame 1, a lower frame 2, a mullion 3, a reinforcing corner piece 4, a vertical scale 5, a hinge 6, a door knife 7 and Horizontal name 8; Wherein, the structure of a section flower railing is shown in the accompanying drawing with embodiment, and two-section typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com