A kind of high wear-resistant weather-resistant corrosion-resistant coating for locomotives, preparation method and application thereof

A corrosion-resistant, locomotive technology, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as reducing the protective effect of coatings on metals, difficult-to-adhesion coatings, etc., to achieve stable spraying ratio, balanced curing reaction, Strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

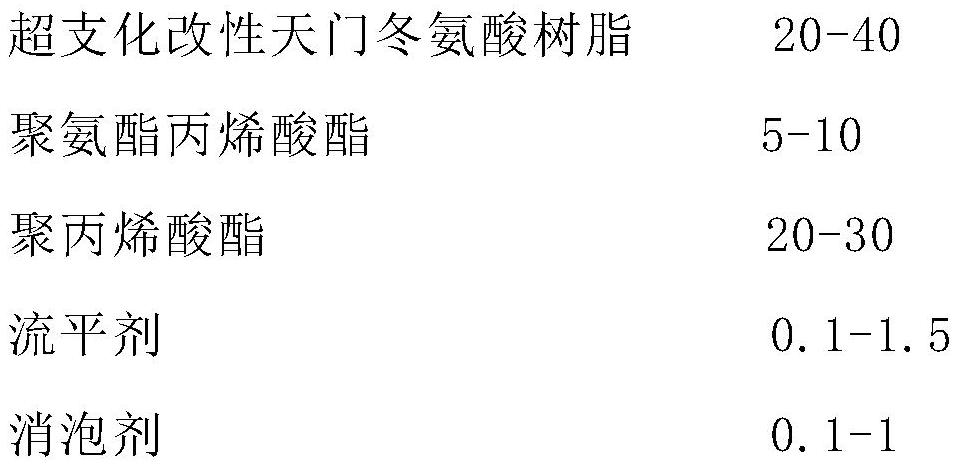

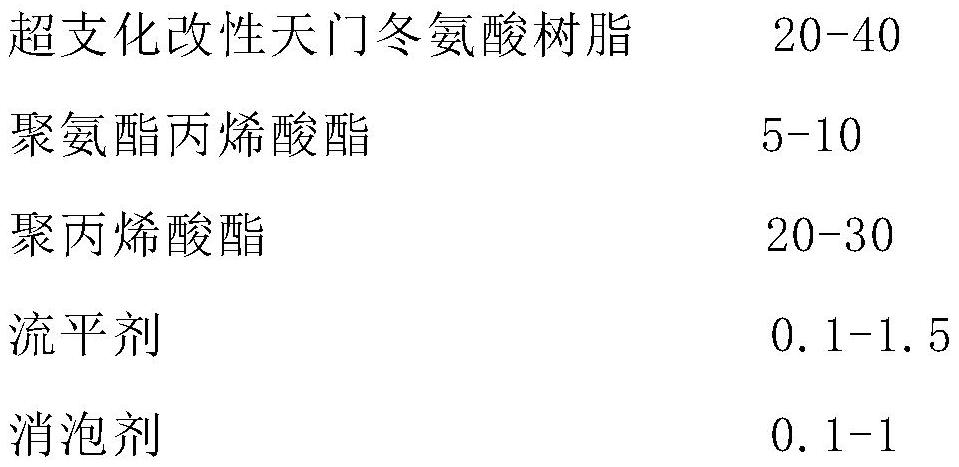

Method used

Image

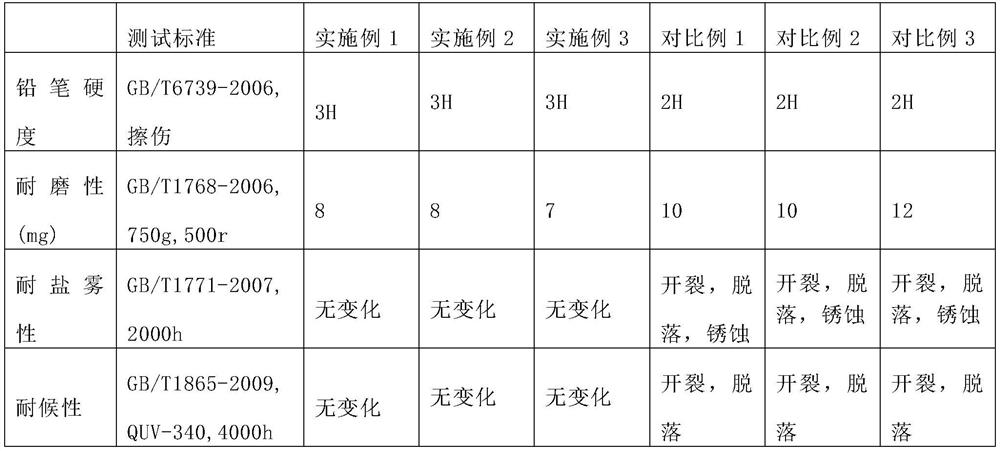

Examples

preparation example Construction

[0033] In one embodiment according to the present invention, the preparation method of the active nano-silica with core-shell structure comprises the following steps: (1) put 100 parts of nano-silicon oxide in absolute ethanol in parts by weight, and ball mill After filtration, continue to ball mill the nano silicon oxide to control the temperature, the temperature is 110-120°C, and the time is 1-5h to obtain pretreated nano silicon oxide; (2) continue to add 10 parts of isocyanate to the pretreated nano silicon oxide, continue ball milling and Control the temperature at 100-110°C for 0.5-2h, then keep ball milling and continue to add butanediamine, the reaction time is 0.5-1h, continue to add dibutyl maleate drop by drop, after the dropwise addition, ball mill for 0.5-1h to get Active nano-silica with core-shell structure.

[0034] In an embodiment according to the present invention, the preparation method of the hyperbranched modified aspartic acid resin comprises the follow...

Embodiment 1

[0052] (1) prepare hyperbranched modified aspartic acid resin:

[0053] (1) In a reaction kettle protected by nitrogen gas, add trichlorosilane ethanol solution with a mass concentration of 10%, add deionized water drop by drop under stirring state, the molar ratio of deionized water to trichlorosilane is 1:3, at temperature React at 75°C for 0.5 hours, then add diisocyanate, and continue to react for 0.5 hours to obtain a pre-reaction solution; (2) water-cooled to control the temperature of the reaction kettle within the range of 15°C, and dropwise in the above-mentioned pre-reaction solution under stirring Add aliphatic primary diamine to end-cap, obtain silicon block branched modified organic diamine reaction solution; (3) Slowly add dialkyl diamine in the above silicon block branched modified organic diamine reaction solution with a titration funnel After the maleic acid ester is added dropwise, the temperature is raised to 90° C. for constant temperature reaction for 10 h...

Embodiment 2

[0060] (1) prepare hyperbranched modified aspartic acid resin:

[0061] (1) In a reaction kettle protected by inert gas, add trichlorosilane ethanol solution with a mass concentration of 30%, add deionized water drop by drop under stirring state, the molar ratio of deionized water to trichlorosilane is 1:3, in React at a temperature of 85°C for 1 hour, then add diisocyanate, and continue the reaction for 1 hour to obtain a pre-reaction solution; (2) water-cooling to control the temperature of the reaction kettle within the range of 20°C, and gradually add in the above-mentioned pre-reaction solution under stirring Add aliphatic primary diamine dropwise to end capping to obtain a silicon block branched modified organic diamine reaction liquid; (3) slowly add dioxane dropwise into the above silicon block branched modified organic diamine reaction liquid with a titration funnel After the dropwise addition of maleic acid ester, the temperature was raised to 100°C for constant temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com